A kind of intelligent control method for electrode lifting of fused magnesium furnace

A technology of electrode lifting and fused magnesia furnace, applied in electric heating devices, electrical components, improving energy efficiency, etc., can solve the problems of unstable control, low content of high-grade products, and high energy consumption of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

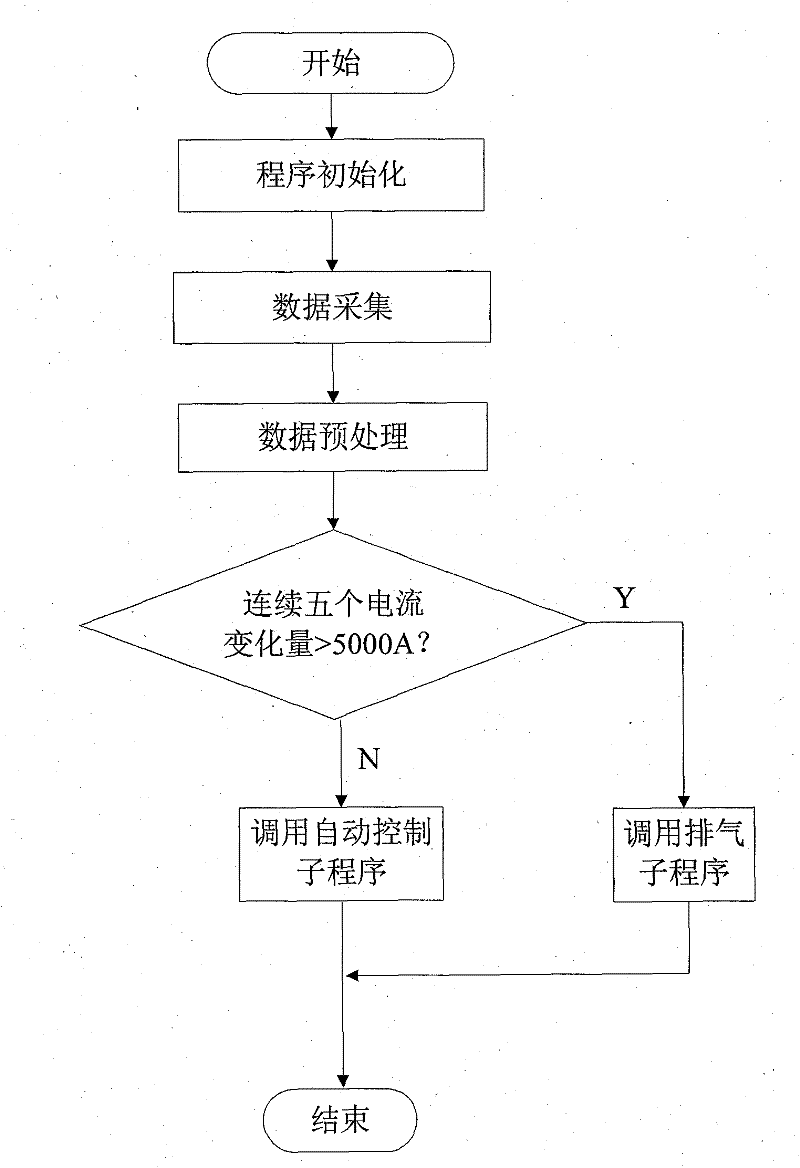

[0218] Such as figure 1 As shown, an intelligent control method for the lifting of electrodes of a fused magnesium furnace, which uses a lifting device for an electrode of a fused magnesium furnace, includes the following steps:

[0219] Step 1: Perform program initialization;

[0220] Program initialization includes setting the program interrupt time, assigning initial values to variables, clearing flags, etc.

[0221] Step 2: Carry out data collection;

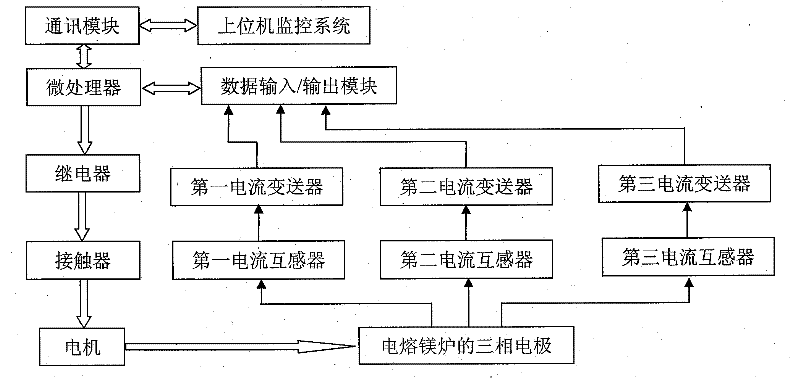

[0222] The real-time instantaneous value of the three-phase current is collected through the data input / output module EM235 and stored in the PLC memory.

[0223] Step 3: Preprocessing the collected data;

[0224] During the smelting process of fused magnesia, the working conditions in the furnace change drastically and the interference is serious. These disturbances have a serious impact on the instantaneous value of the three-phase current in the process data, so it is necessary to filter the collected instantaneous ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com