Efficient energy-saving full-automatic electric magnesium melting revolving furnace

A fully automatic, fused magnesium technology, used in furnaces, furnace types, lighting and heating equipment, etc., can solve the problems of electrode sintering dead corners, furnace penetration, external leakage, etc., to save resources and energy, ensure a stable rise, guarantee The effect of operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

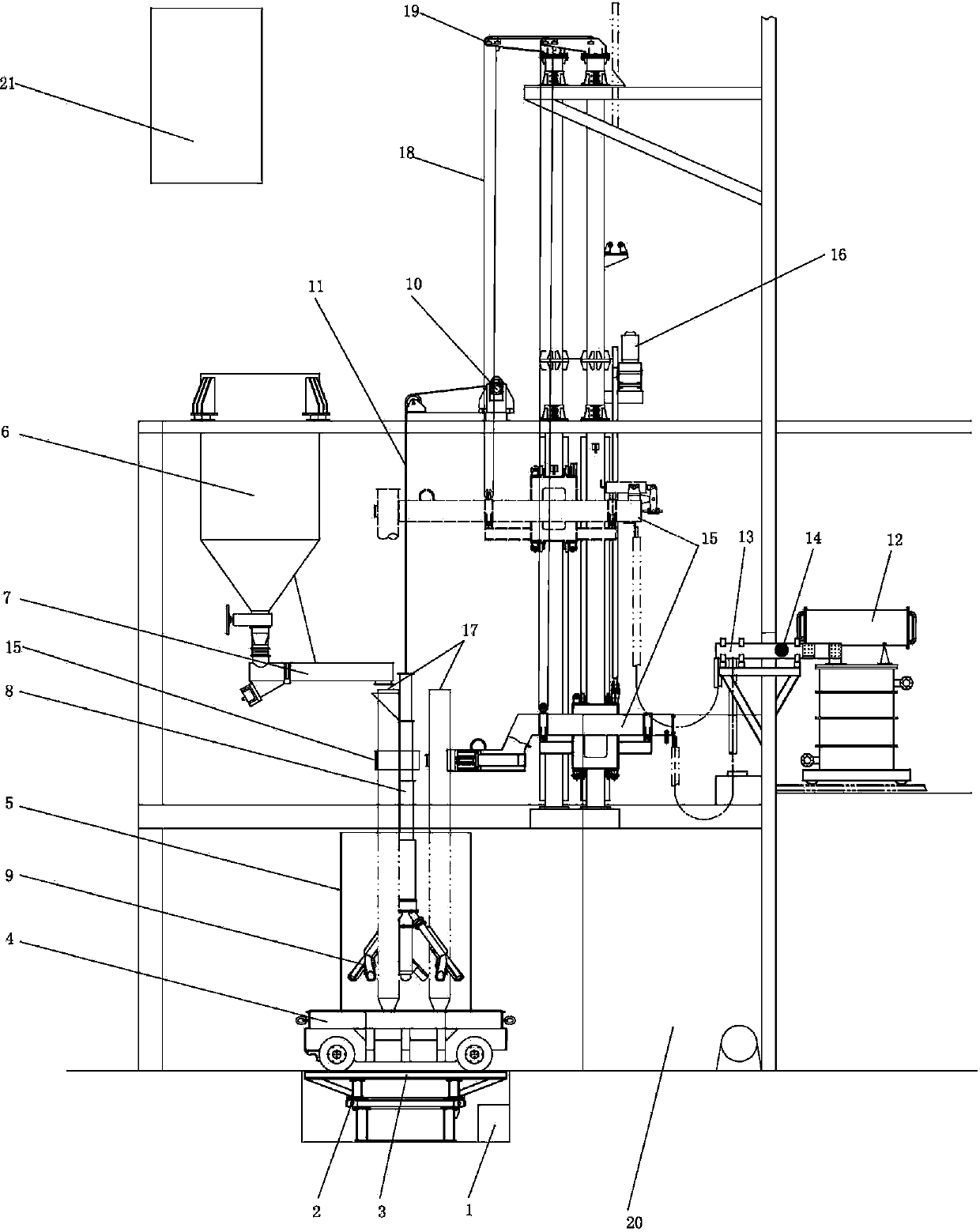

[0008] Such as figure 1 As shown, the high-efficiency and energy-saving electric fused magnesium automatic converter: the furnace bottom rotary reducer (1) drives the furnace bottom rotary plate (3) to rotate through the rotating gear (2), and the furnace bottom rotary plate (3) is equipped with a furnace bottom car ( 4), the furnace bottom car (4) is provided with a converter (5).

[0009] The silo (6) communicates with the cloth lifting telescopic pipe (8) through the tube type vibrating feeder (7). The cloth lifting telescopic pipe (8) is a four-section telescopic pipe, and the end of the cloth lifting telescopic pipe (8) Evenly distribute the six-claw spreader (9), and the hoist (10) drives the cloth lifting telescopic tube (8) to expand and contract through the wire rope I (11), and then drives the six-claw spreader (9) to move up and down.

[0010] The transformer (12) is connected with the short network system (13), and the short network system (13) is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com