Simulated temperature measuring method for rubber tires

A technology of rubber tires and temperature measuring devices, applied to thermometers, thermometers using directly heat-sensitive electric/magnetic elements, measuring devices, etc., can solve the problem of less number of temperature measurements, affecting data accuracy, consuming a lot of material and financial resources, etc. problem, to achieve the effect of optimizing formula, shortening vulcanization time and improving tire quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

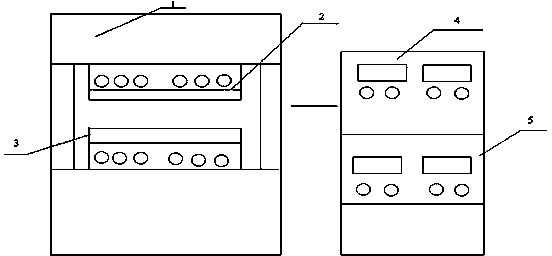

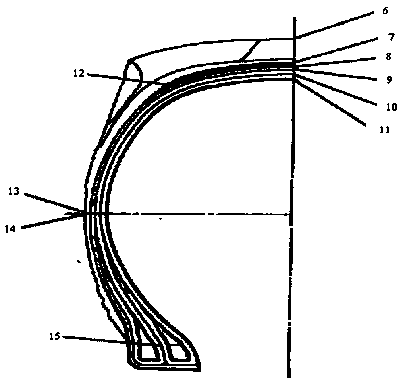

[0017] Such as figure 1 As shown, the rubber tire simulation device of the present invention includes a frame 1 and an upper template 2 and a lower template 3 installed on the upper and lower parts of the frame 1, and the upper and lower templates are respectively controlled by the upper template temperature measuring and controlling instrument 4 and the lower template temperature measuring and controlling instrument 5. For temperature measurement and control. The E-type thermocouple used as the hot end temperature measuring probe has a diameter of 0.3mm and a diameter of 0.6 mm after being covered with a polytetrafluoroethylene insulating layer. It is pre-embedded in the designated temperature measuring position during the tire building process. The designated temperature measurement site (such as figure 2 shown) E-type thermocouples coated with polytetrafluoroethylene are buried in the designated positions during the tire building process. figure 2 6 is model-tread, 7 tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com