Camera module group image test system and method

A camera module and testing system technology, applied in the camera body, camera, photography and other directions, can solve the problems of large light box, waste of test man-hours, large space required for testing, etc., to reduce test space and test man-hours. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

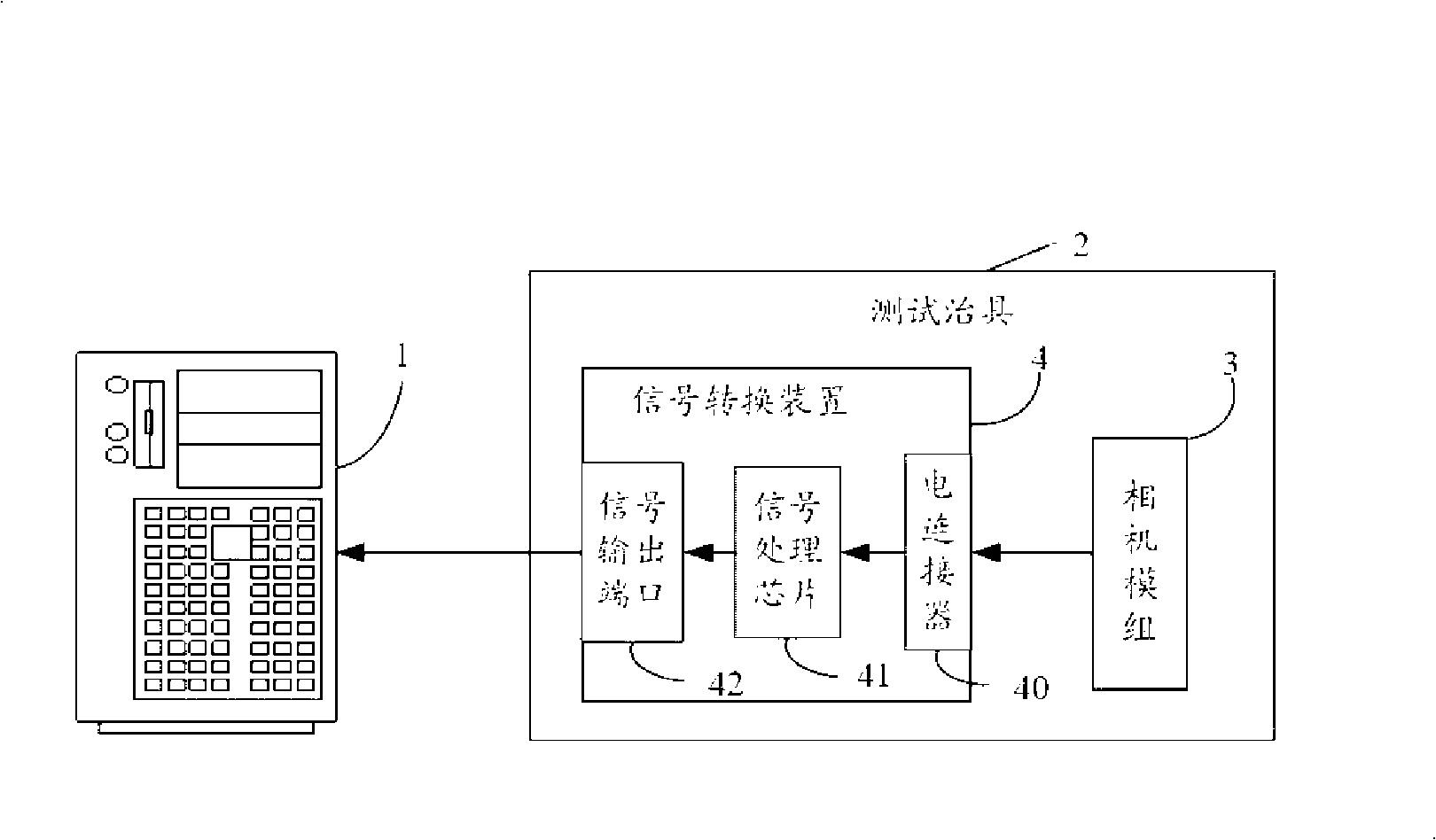

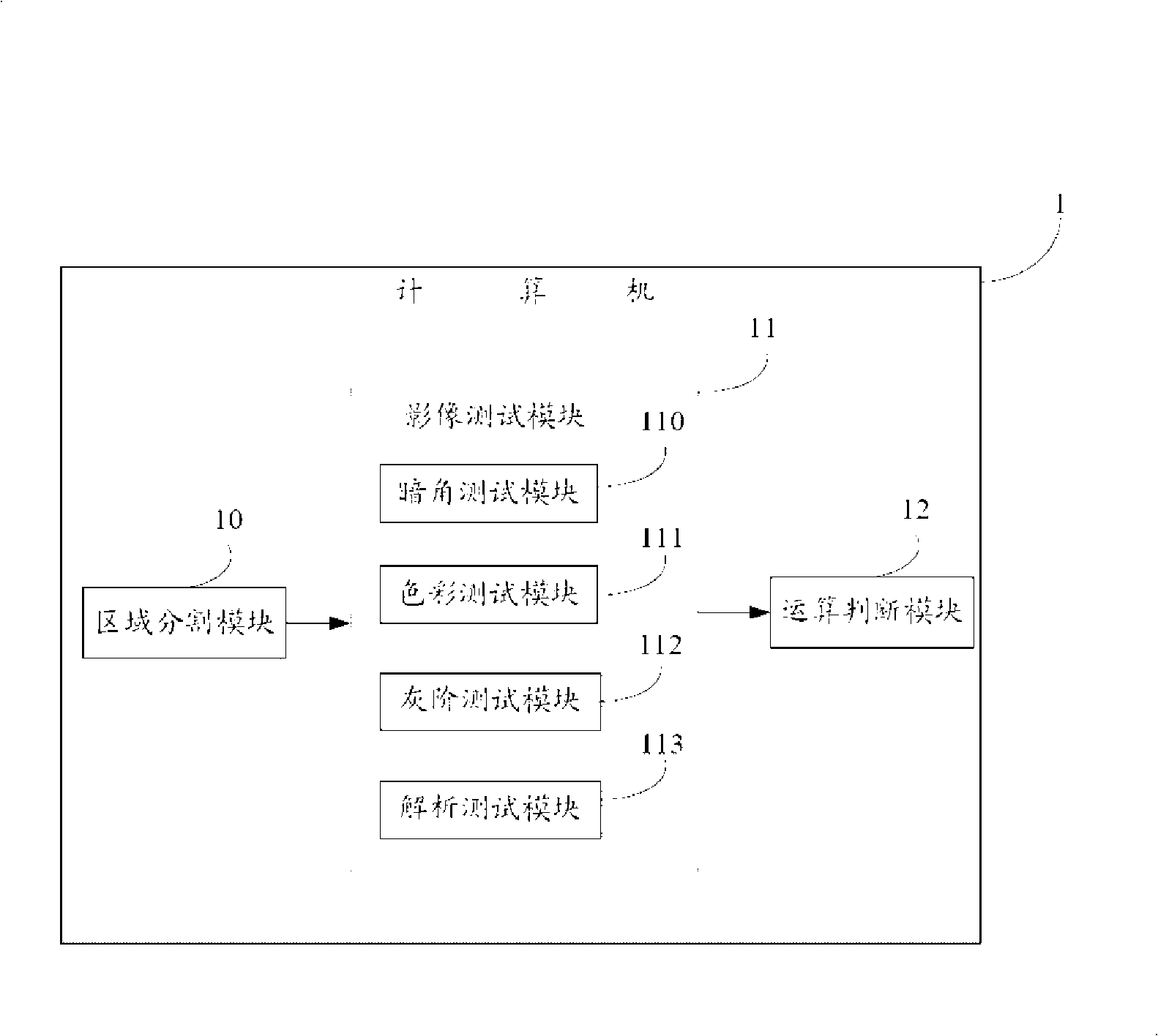

[0023] refer to figure 1 Shown is a system architecture diagram of a preferred embodiment of the image testing system for the camera module of the present invention. The video test system mainly includes a computer 1 and a test fixture 2 . The test fixture 2 is used to install the camera module 3 to be tested, and is provided with a mounting hole for the camera module 3 to be installed and a fastener (not shown) on the edge of the mounting hole. The measured camera module 3 is stably fixed on the mounting hole. A signal conversion device 4 is installed on the test fixture 2 for converting the image signal output by the camera module 3 to be tested into an image signal format that can be recognized by the computer 1 . The signal conversion device 4 includes an electrical connector 40 for connecting the camera module 3 to be tested, at least one signal processing chip 41 for signal conversion and a signal output port 42 for connecting to the computer 1 . The electrical connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com