An ink-cartridge for printers

A technology for printers and ink cartridges, applied in printing and other directions, can solve the problems of smaller space for filling ink, increased manufacturing costs, and poor quality of output products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

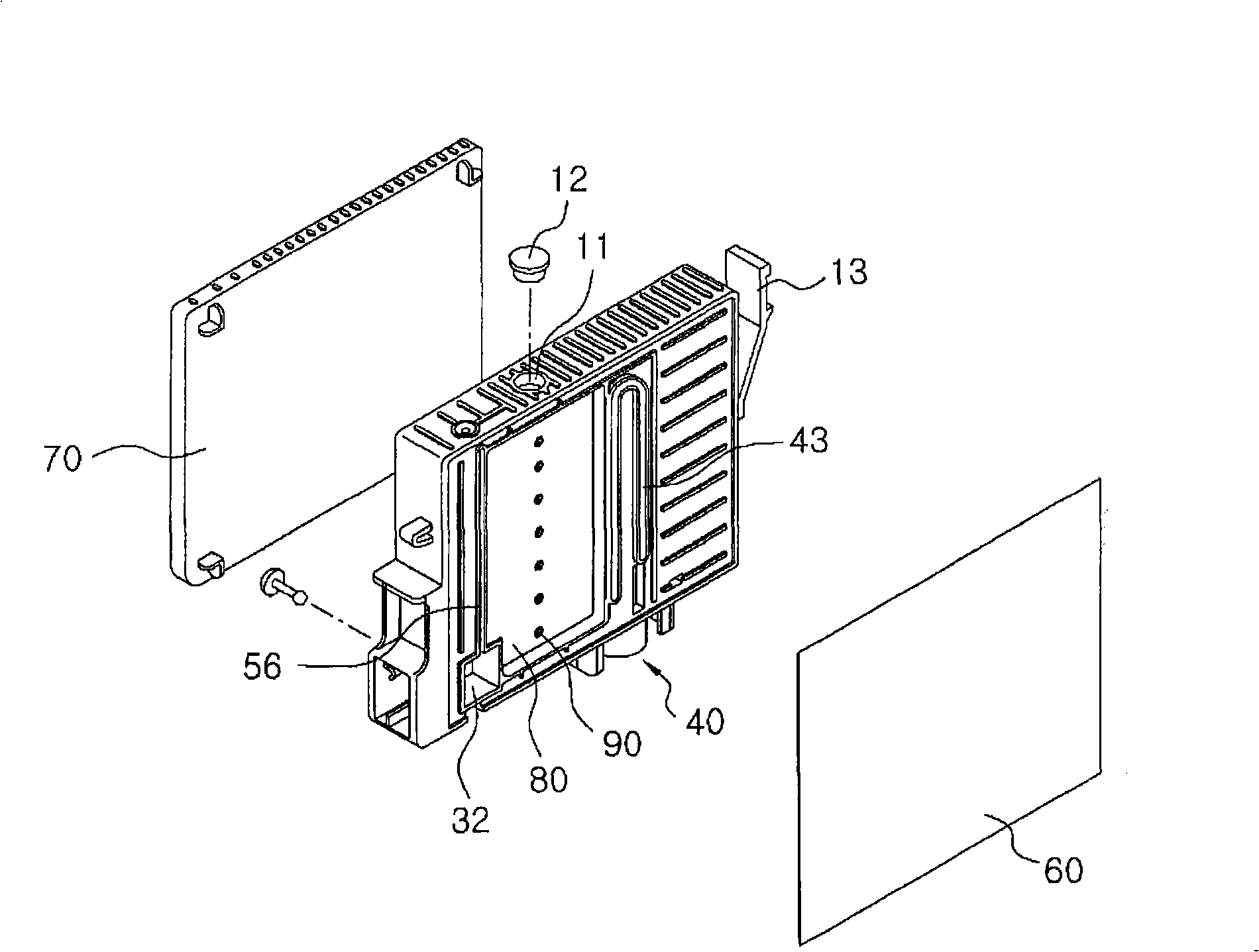

[0040] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

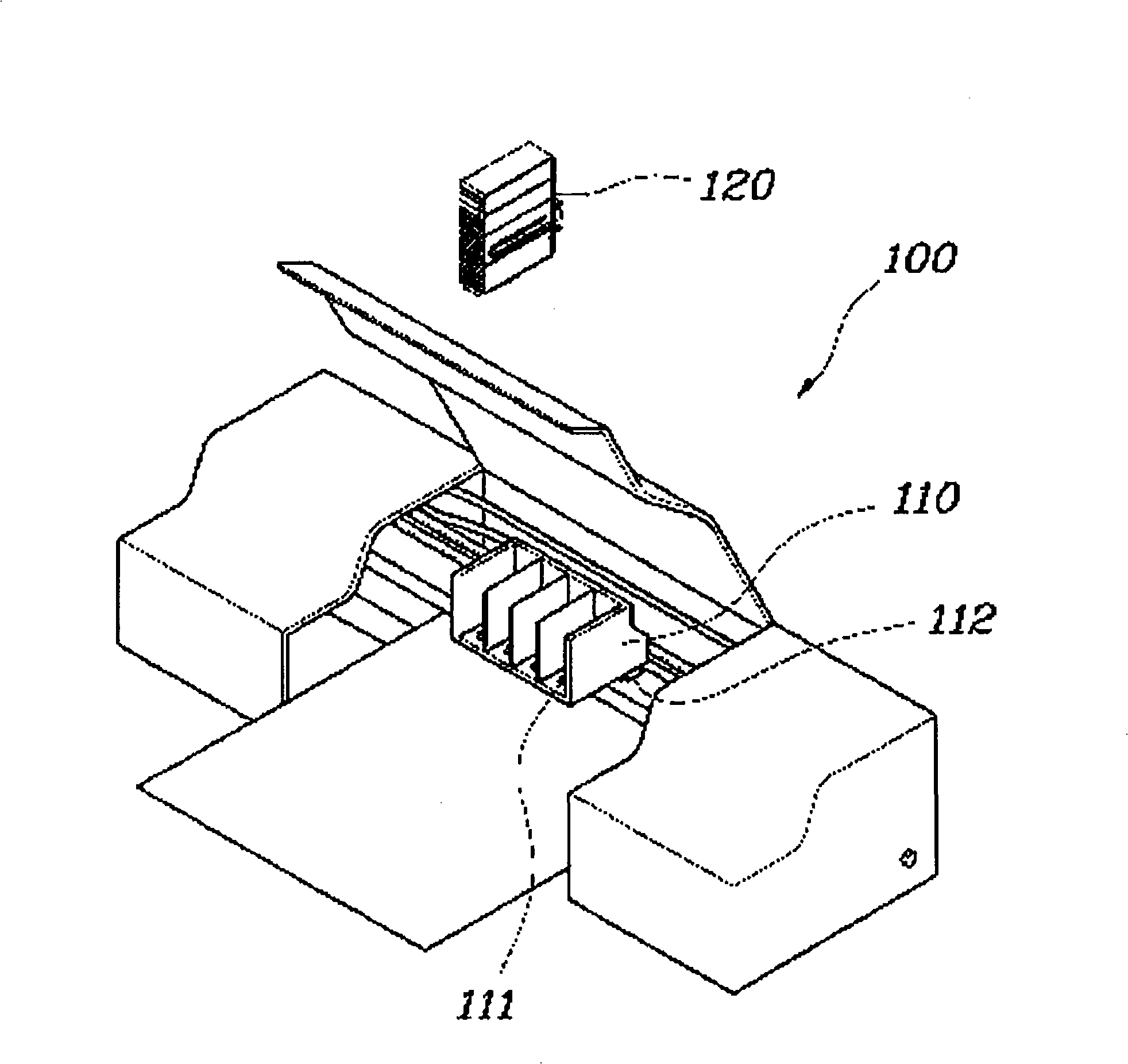

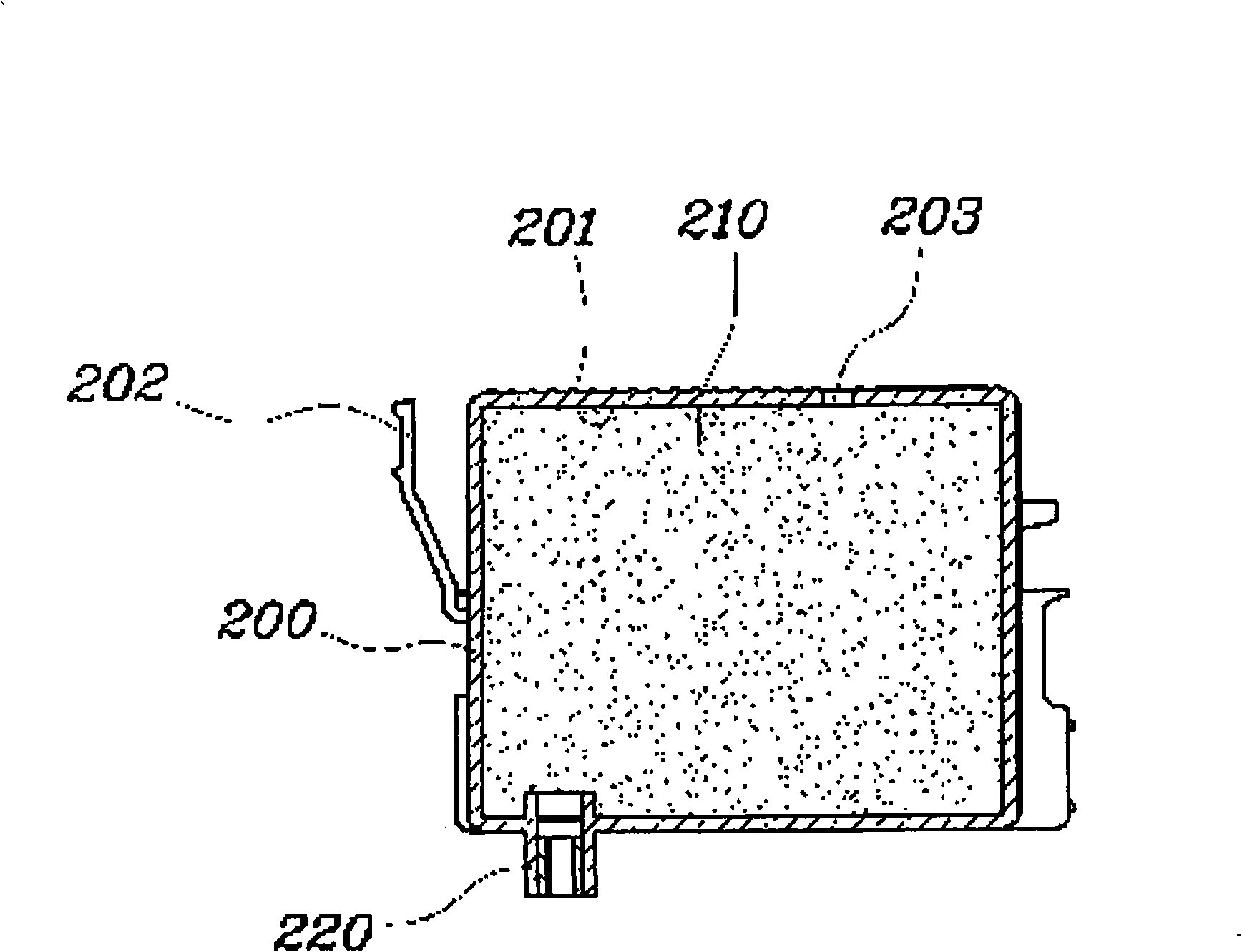

[0041] image 3 is an exploded perspective view showing an ink cartridge according to the present invention, Figure 4 is a front view showing an ink cartridge according to the present invention, Figure 5 is a rear view illustrating the ink discharge process of the ink cartridge according to the present invention.

[0042] As described herein, the present invention is provided with a body 10 formed into a predetermined size, a filling hole 11 is formed at the top surface of the body 10, the filling hole 11 is plugged by a rubber stopper 12 after ink is filled, and the outer side surface of the body 10 A retaining arm 13 is formed at to generate a retaining force when engaged to a head mounted on the printer. In addition, a pressure regulating part 80 is formed on the outer wall surface of the body 10, the pressure regulating part communicates with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com