Flat Shoulder Plastic Extrusion Flat Die

A die head and plastic technology, applied in the field of flat-shouldered plastic extrusion flat die head, can solve the problems of incomplete thickness in the horizontal direction of the product, deviation and unevenness of the die head clam shell, etc., and achieve consistency in thickness and physical properties Good, avoid clam shell deviation and reduce the scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

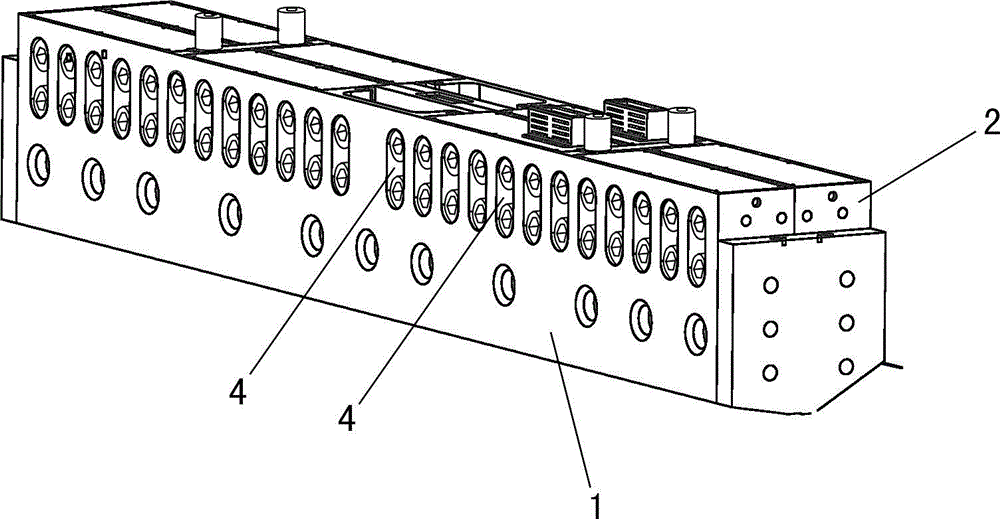

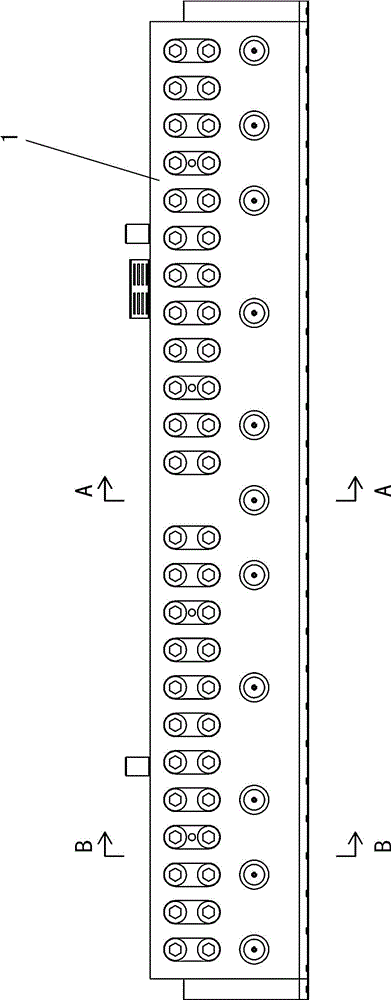

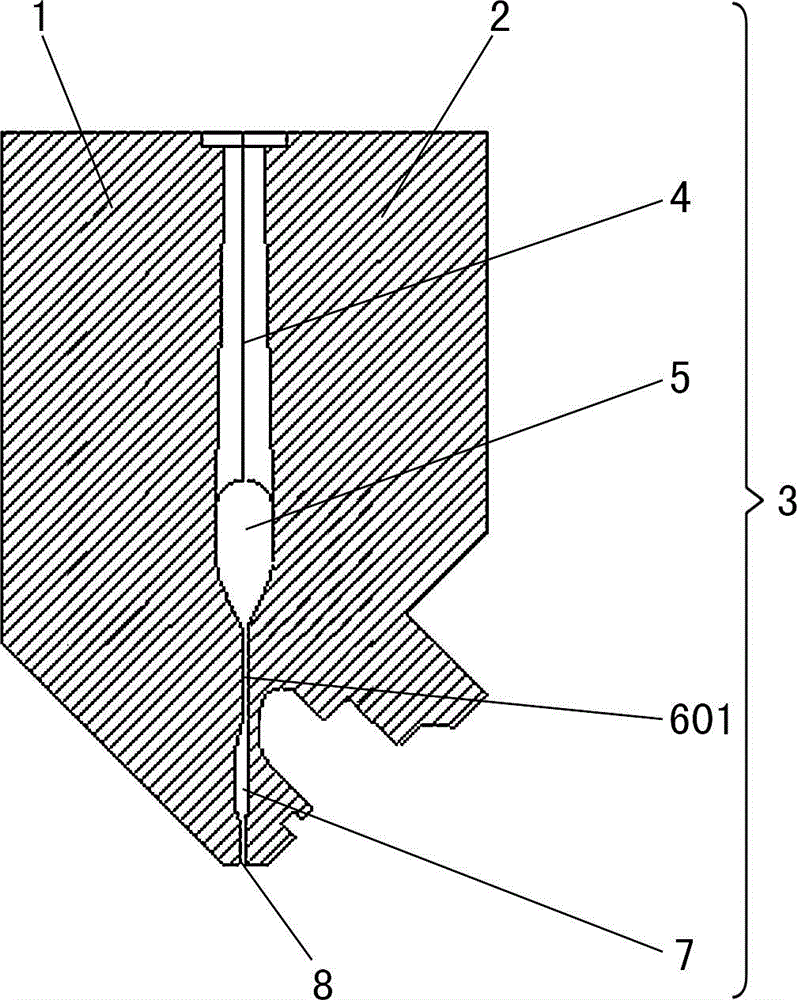

[0017] Such as Figure 1-5 As shown, the flat-shoulder plastic extrusion flat die in this embodiment includes a first die assembly 1 and a second die assembly 2, the inner side of the first die assembly 1 and the inner side of the second die assembly 2 An extrusion flow channel 3 is formed therebetween, and the extrusion flow channel 3 sequentially includes a feed zone 4, a diffusion zone 5, a distribution zone 6 and an extrusion zone 7 from top to bottom.

[0018] The top edge of the diffusion zone 5 is a straight line segment, and the top edge of the diffusion zone 5 is parallel to the die lip 8 at the bottom end of the flat-shoulder plastic extrusion die. The die lip 8 at the bottom of the flat-shoulder plastic extrusion die refers to the bottom edge of the flat-shoulder plastic extrusion die.

[0019] The distribution area 6 includes a first-level choke distribution area 601 and two second-level distribution areas 602. The bottom of the first-level choke distribution area 601 ...

Embodiment 2

[0027] The difference between the flat-shoulder plastic extrusion flat die in this embodiment and the first embodiment is:

[0028] The gap range at the apex of the first-level choke distribution area 601 is 0.5 mm, and the gap range at the outer end of the first-level choke distribution area 601 is 4.5 mm; the second-level distribution area 602 is The gap range at the intersection of the central axis 9 of the outlet flow channel is 0.5 mm, and the gap range at the outer end of the second-level distribution area 602 is 4.5 mm.

Embodiment 3

[0030] The difference between the flat-shoulder plastic extrusion flat die in this embodiment and the first embodiment is:

[0031] The gap range at the apex of the isosceles triangle of the first-level choke distribution area 601 is 0.4 mm, and the gap at the outer end of the first-level choke distribution area 601 is 3.8 mm; the second-level distribution area 602 is The gap range at the intersection of the central axis 9 of the outlet flow channel is 0.4 mm, and the gap range at the outer end of the second-level distribution area 602 is 3.8 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com