Heat-shrinkable mandrel airbag and its manufacturing process and application method

A manufacturing process and heat-shrinkable technology, applied in the field of heat-shrinkable mandrel airbags, can solve the problems of demanding molding conditions and difficult to achieve, and achieve the effects of avoiding structural deformation of the mandrel, facilitating stress transfer, and convenient laying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

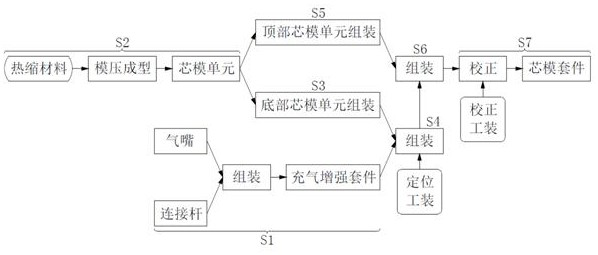

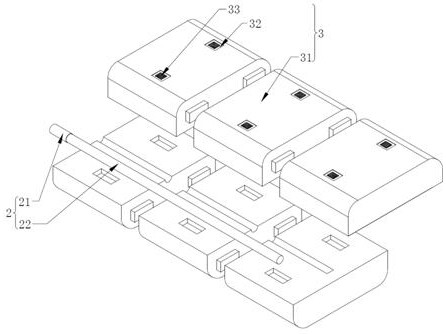

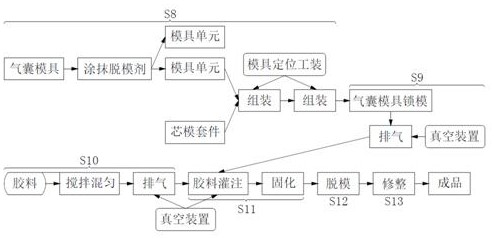

[0038] Please also see figure 1 and figure 2 , respectively are the production process flow chart and structural diagram of the core mold set in the manufacturing process of the heat-shrinkable mandrel airbag provided by the present invention.

[0039] The manufacturing process of heat-shrinkable mandrel airbag specifically comprises the following steps:

[0040] S1: Manufacture the inflation enhancement kit 2, including the gas nozzle 21 and the connecting rod 22.

[0041] Wherein said gas nozzle 21 is copper gas nozzle, adopts hexagonal brass tube to process, and carries out surface treatment before use, to increase the adhesion with the air bag. The connecting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com