Aluminum alloy rod bar mould

A technology for aluminum alloys and rods, which is applied in the direction of metal extrusion dies, etc., can solve the problems of increasing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention are specifically described below through several examples, but the present invention is not limited to the following examples.

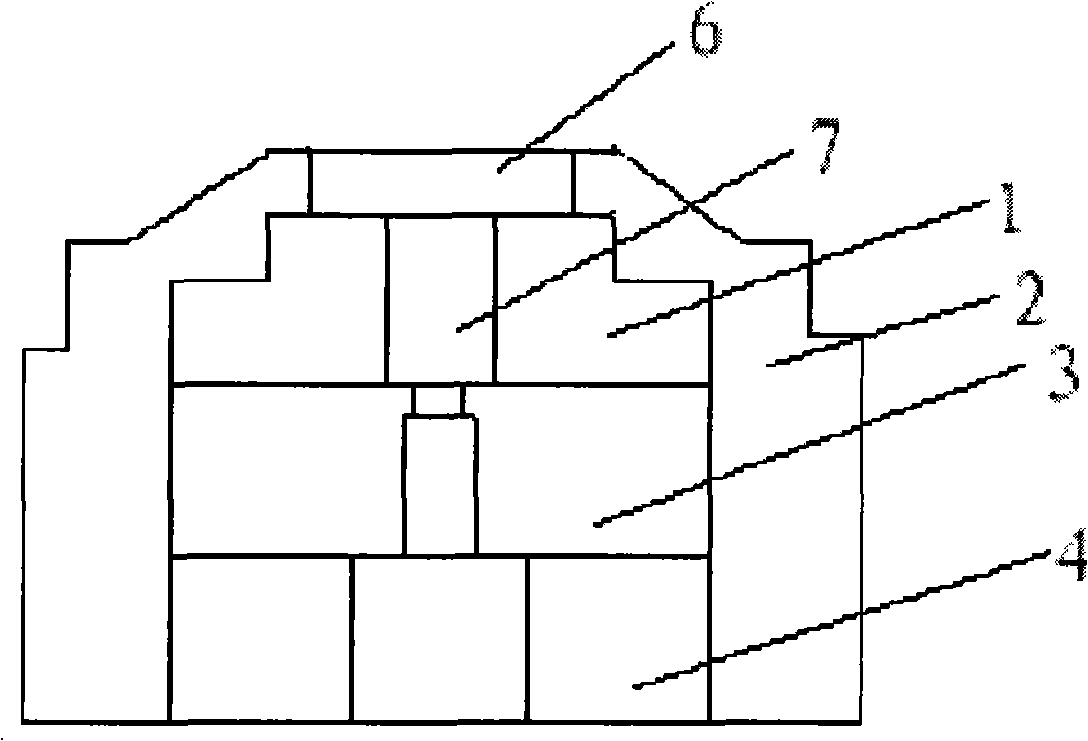

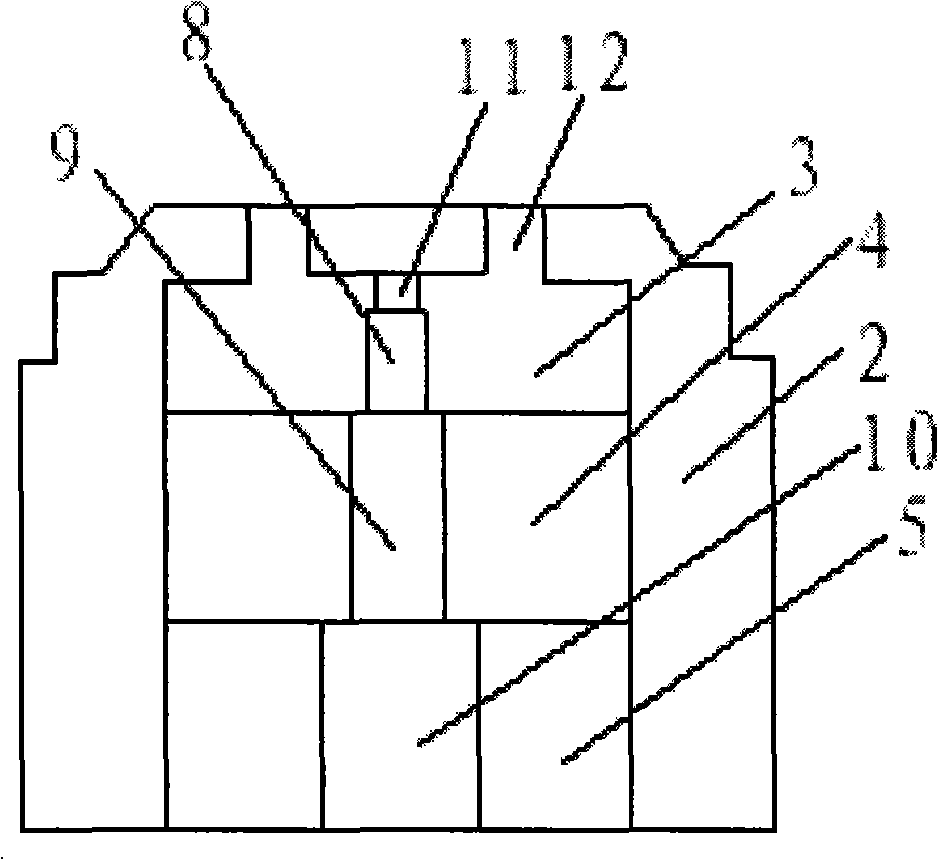

[0015] refer to figure 1 , 2 , an aluminum alloy bar mold, the deflector is removed, the mold body is directly in contact with the aluminum rod for extrusion, the production and process have been changed accordingly, by controlling the extrusion speed and the temperature of the aluminum rod Wait for a series of parameters to control the layering phenomenon at the end of the bar; remove the transition area of the mold sleeve, let the mold directly expose to the outside for extrusion, and through such rectification, the layering phenomenon of the bar is basically solved.

[0016] An aluminum alloy bar mold, the guide plate 1 is removed, the transition area 6 of the mold cover 2 is removed, and a rear mold pad 5 is added, including the mold sleeve 2, the mold body 3, the mold pad 4, and the rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com