Energy-saving phase-change interior wall water-based paint and preparation method thereof

A technology for interior walls and water-based paints, applied in the field of coatings, can solve the problems of affecting the effect of phase change energy storage of coatings, reducing the use efficiency of phase change materials, and affecting the service life of coatings, etc., so as to enhance the antioxidant capacity and improve the temperature adjustment effect , the effect of improving the efficiency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

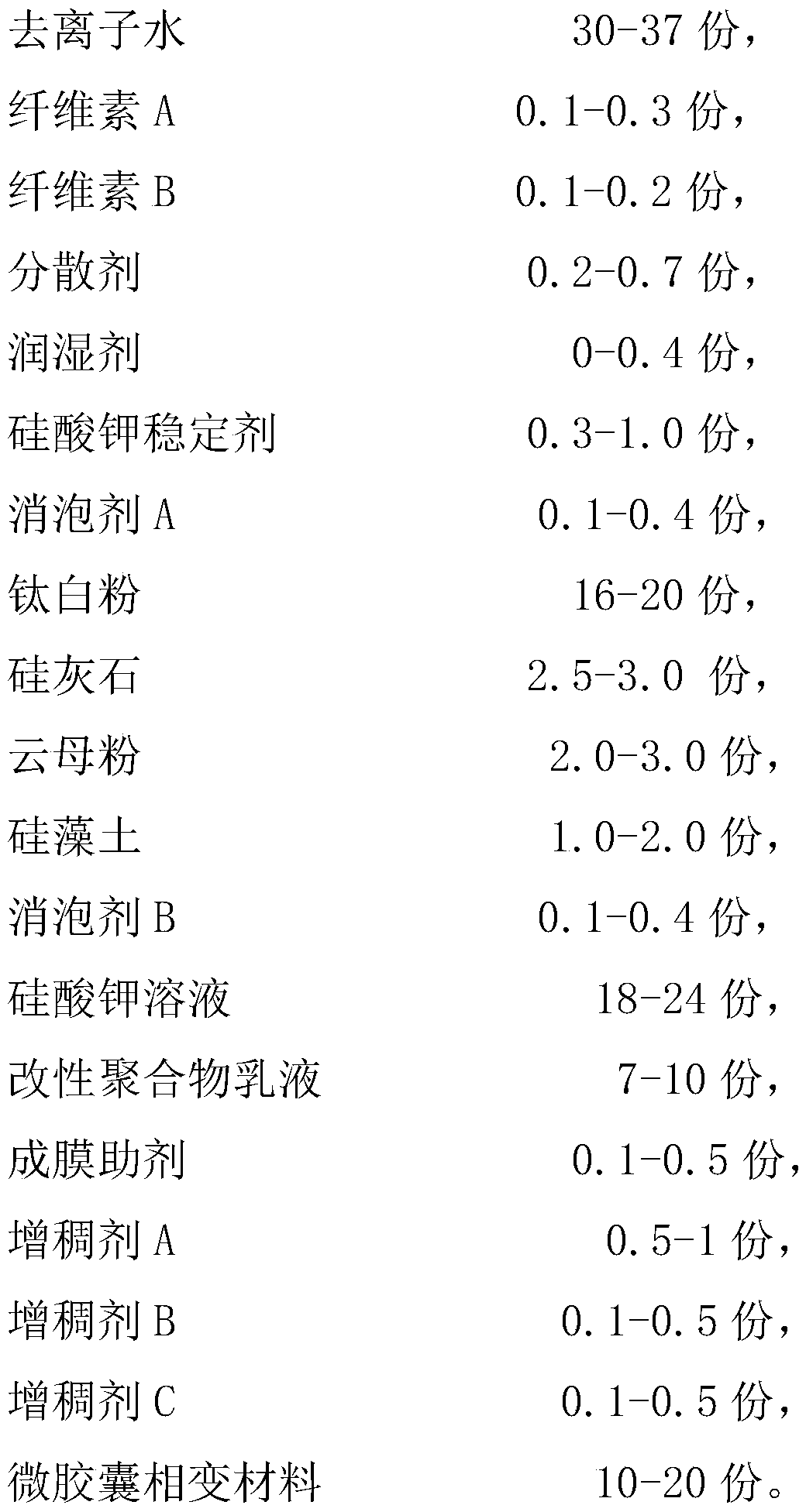

[0031] An energy-saving phase-change interior wall water paint, comprising the following raw material components in mass percentage:

[0032]

[0033]

[0034] The preparation method of the energy-saving phase-change interior wall water paint comprises the following steps:

[0035] (1) Under the stirring state of 450r / min, add cellulose A and B respectively to the deionized water, carry out the mixing treatment with the stirring rate of 700r / min, the stirring time is 8min, and obtain the first material;

[0036] (2) Add dispersant, wetting agent, potassium silicate stabilizer, and defoamer A to the first material in sequence, and carry out mixing treatment at a stirring rate of 700r / min, and the stirring time is 8min, to obtain the second blend;

[0037] (3) Add titanium dioxide, wollastonite, mica powder, and diatomaceous earth to the second mixed material in sequence, and mix with a stirring rate of 1700r / min for 35 minutes to obtain a third mixed material;

[0038] ...

Embodiment 2

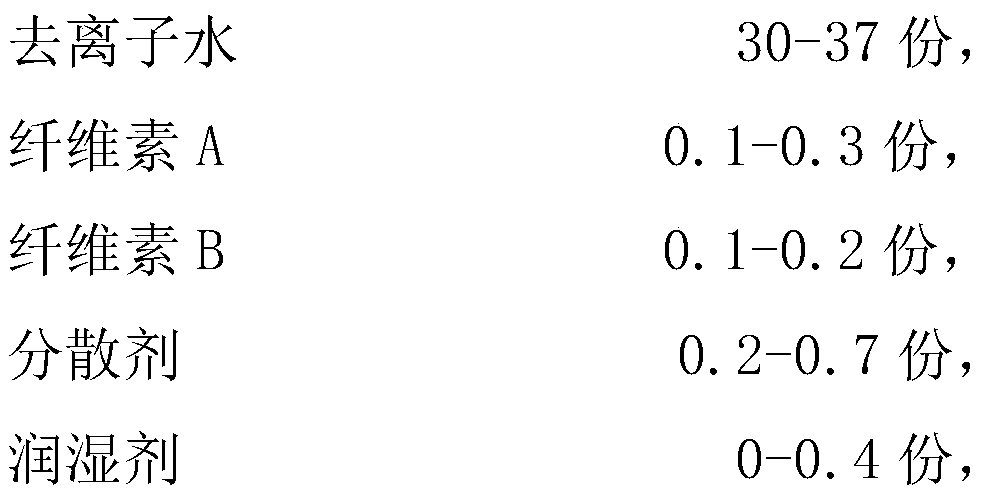

[0040] An energy-saving phase-change interior wall water paint, comprising the following raw material components in mass percentage:

[0041]

[0042]

[0043] The preparation method of the energy-saving phase-change interior wall water paint comprises the following steps:

[0044] (1) Under the stirring state of 480r / min, cellulose A and B were respectively added to the deionized water, and the mixing process was carried out at a stirring rate of 690r / min, and the stirring time was 7min to obtain the first material;

[0045] (2) Add dispersant, wetting agent, potassium silicate stabilizer, and defoamer A to the first material in sequence, and carry out mixing treatment at a stirring rate of 750r / min, and the stirring time is 9min, to obtain the second blend;

[0046] (3) Add titanium dioxide, wollastonite, mica powder, and diatomaceous earth to the second mixed material in sequence, and mix at a stirring rate of 1600r / min for 37 minutes to obtain a third mixed material; ...

Embodiment 3

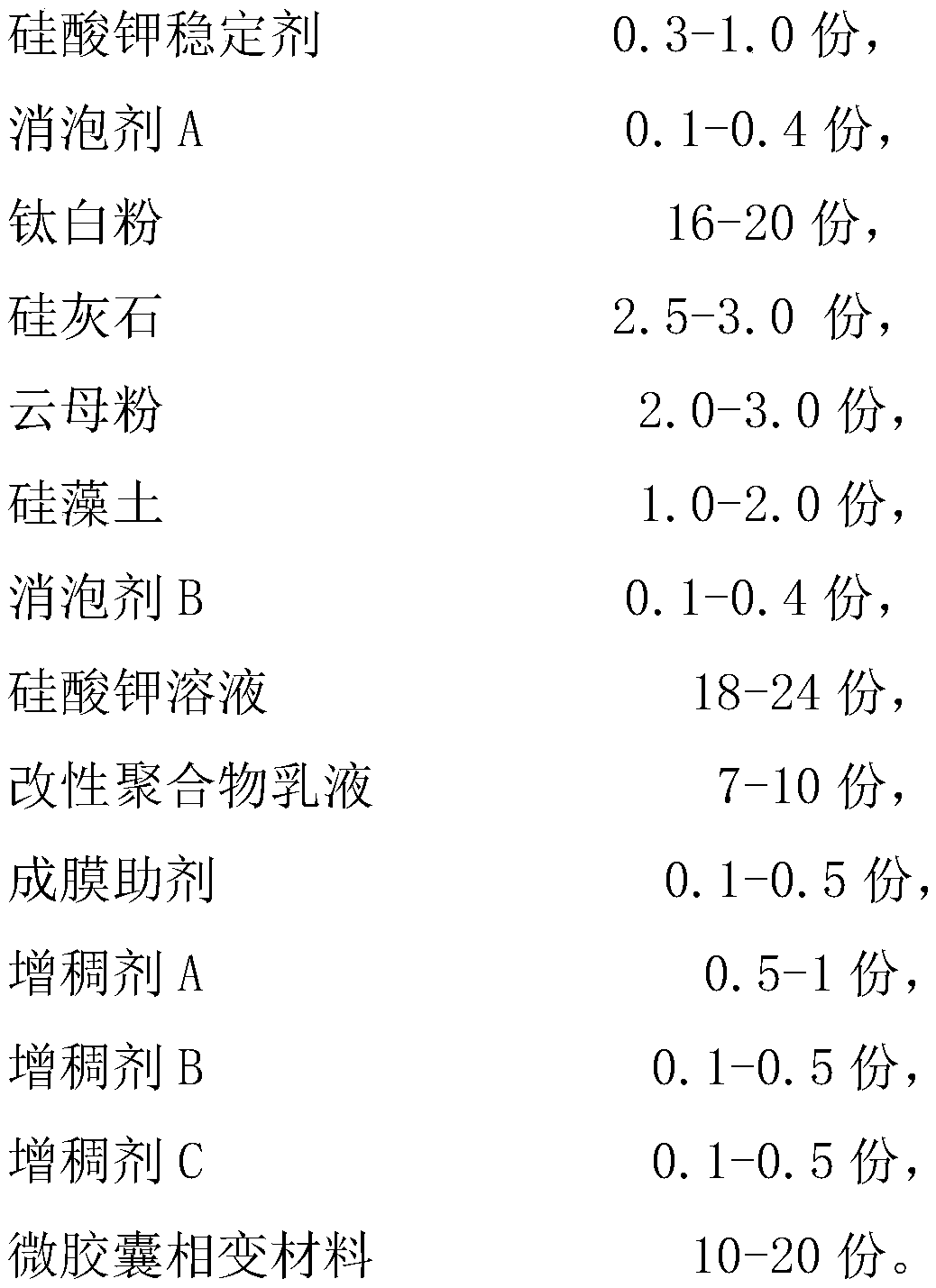

[0049] An energy-saving phase-change interior wall water paint, comprising the following raw material components in mass percentage:

[0050]

[0051]

[0052] The preparation method of the energy-saving phase-change interior wall water paint comprises the following steps:

[0053] (1) Under the stirring state of 400r / min, add cellulose A and B respectively to the deionized water, carry out the mixing treatment with the stirring speed of 800r / min, the stirring time is 5min, and obtain the first material;

[0054] (2) Add dispersant, wetting agent, potassium silicate stabilizer, and defoamer A to the first material in sequence, and carry out mixing treatment at a stirring rate of 800r / min, and the stirring time is 5min, to obtain the second blend;

[0055] (3) Add titanium dioxide, wollastonite, mica powder, and diatomaceous earth to the second mixed material in sequence, and mix with a stirring rate of 1800r / min for 30 minutes to obtain a third mixed material;

[0056]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com