Method for removing foreign flavor of silicon rubber products

A technology of silicone rubber and thermally vulcanized silicone rubber, which is applied in the field of silicone rubber products vulcanized by organic peroxide vulcanizing agents to eliminate the peculiar smell of silicone rubber products. It can solve the problems of inability to eliminate odors, pungent and unpleasant odors, etc. Sexual Odor Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Add 16g of β-cyclodextrin to the kneader, 400g of hydroxyl-terminated polydimethylsiloxane with a molecular weight of 3400, and 2000g of 50% p-toluyl peroxide, mix well, grind evenly, and get a paste Composite vulcanizing agent finished product. Take 10Kg of thermally vulcanized silicone rubber, add 200g of the above-mentioned pasty compound vulcanizing agent finished product, and knead evenly on an open mill. The compounded rubber is often vulcanized by hot air, the temperature of the tunnel oven is 300°C, and the residence time of the extruded rubber hose in the oven is 45s. Squeeze Hose is completely odorless.

Embodiment 2

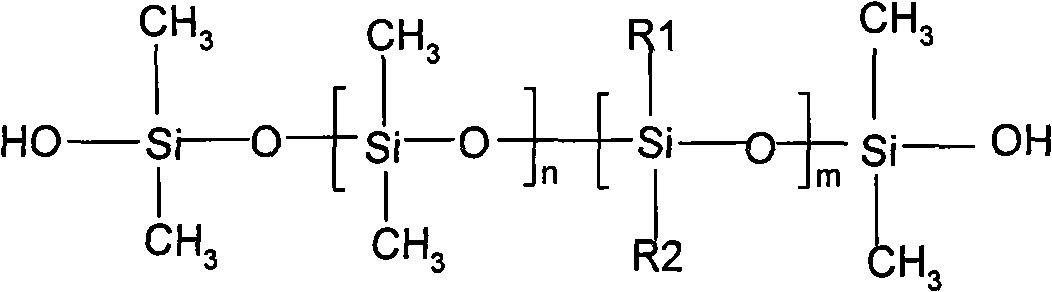

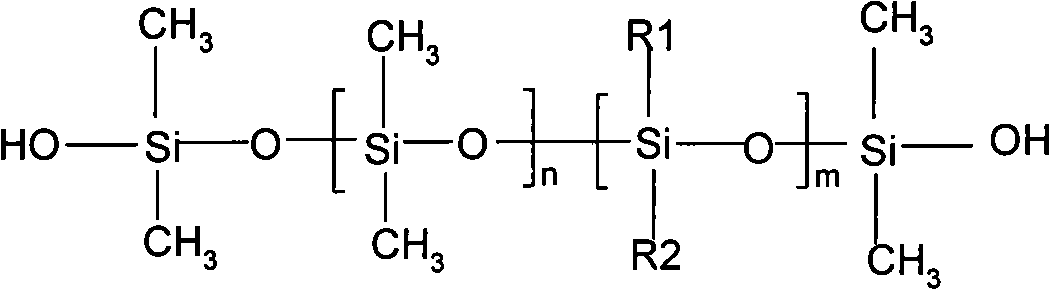

[0023] Add 40g of α-cyclodextrin to the kneader, 300g of hydroxyl-terminated dimethyl vinyl polysiloxane with a molecular weight of 2800, and 2000g of 50% o-toluyl peroxide, mix well, and grind evenly , to obtain the finished product of pasty compound vulcanizing agent. Take 10Kg of hot vulcanized silicone rubber, add 150g of the above-mentioned pasty compound vulcanizing agent finished product, mix evenly on an open mill, add 10g of cetyl secondary amine paste accelerator with a content of 20%, and mix evenly again. The compounded rubber is often vulcanized by hot air, the temperature of the tunnel oven is 300°C, and the residence time of the extruded rubber hose in the oven is 45s. Squeeze Hose is completely odorless.

Embodiment 3

[0025] Add 60g of γ-cyclodextrin to the kneader, 160g of hydroxyl-terminated dimethylmethylphenylpolysiloxane with a molecular weight of 2000, 2000g of 50% p-methoxybenzoyl peroxide, mix well, and grind Evenly, the finished product of pasty compound vulcanizing agent is obtained. Take 10Kg of thermally vulcanized silicone rubber, add 120g of the above-mentioned pasty compound vulcanizing agent finished product, mix evenly on an open mill, add 10g of cetyl secondary amine paste accelerator with a content of 20%, and mix evenly again. The compounded rubber is often vulcanized by hot air, the temperature of the tunnel oven is 300°C, and the residence time of the extruded rubber hose in the oven is 45s. Squeeze Hose is completely odorless.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com