Full automatic washing machine with big and small washing becks

A fully automatic washing machine and washing tub technology, applied in the field of washing machines, can solve the problems of wasting electric energy and water resources, time-consuming and laborious washing clothes, etc., and achieve the effects of saving water and electricity costs, reasonable washing methods, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

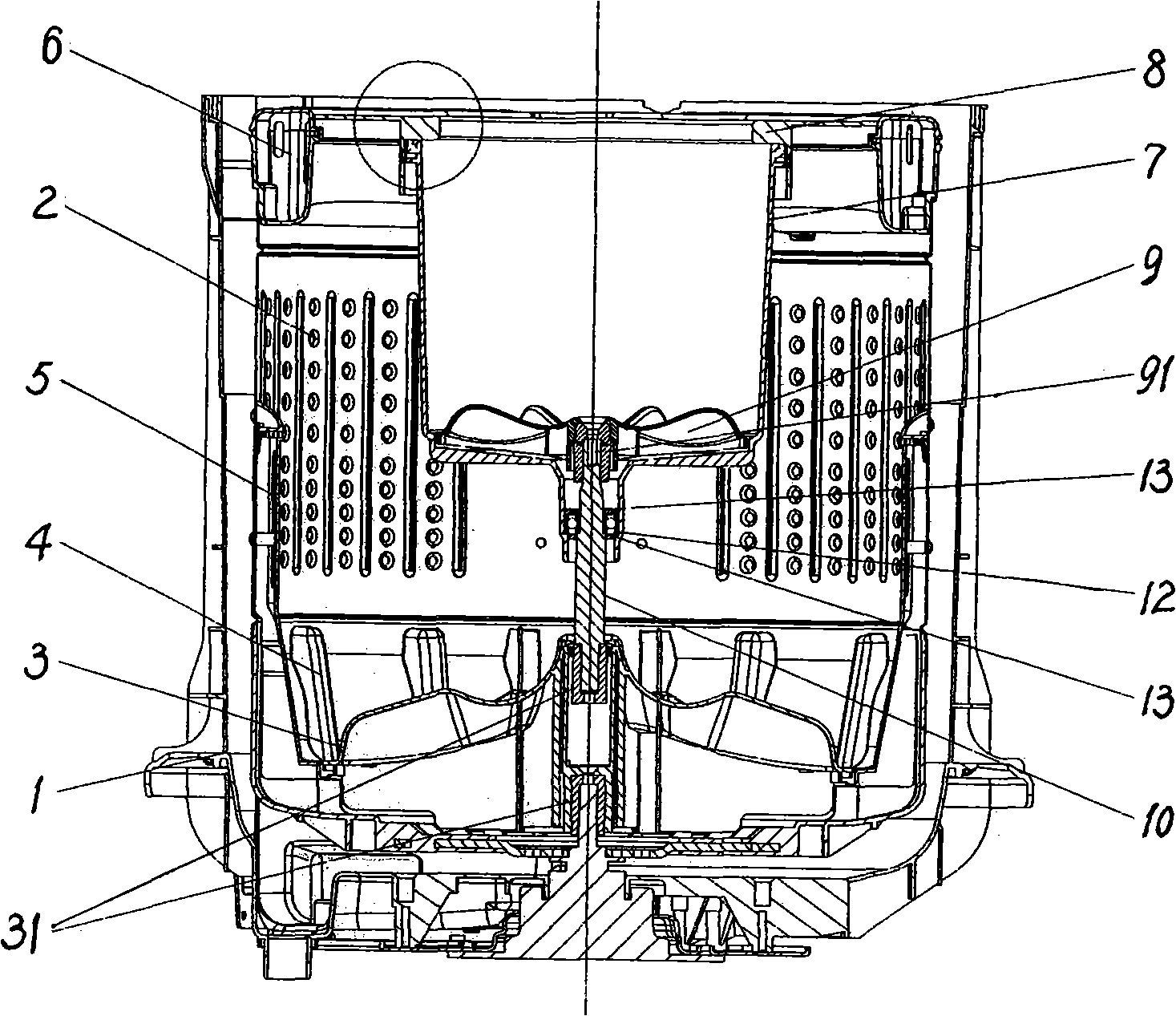

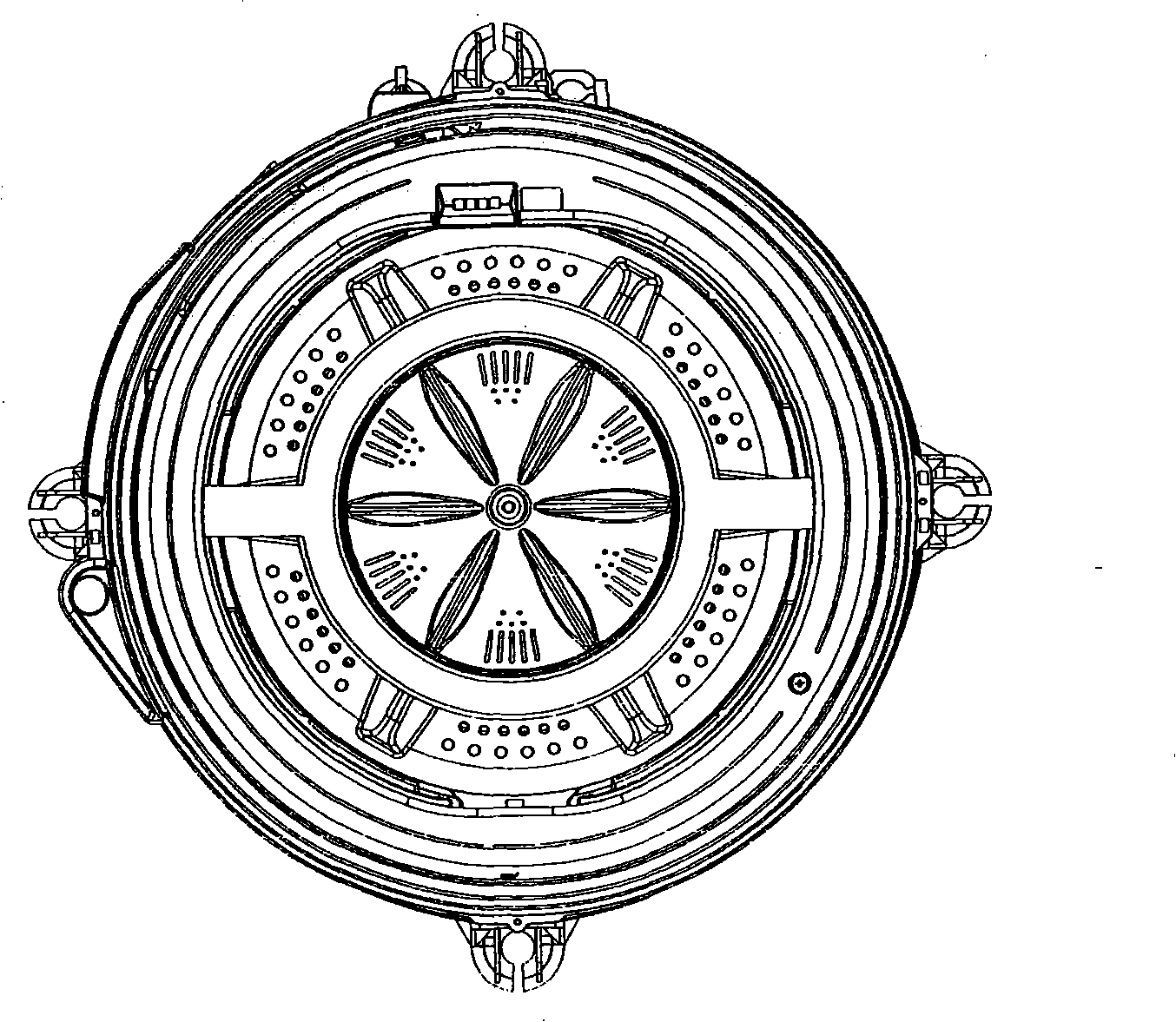

[0021] see Figure 1 to Figure 4 , a kind of full-automatic washing machine with large and small washing buckets of the present invention is equipped with bucket 1, big washing dehydration bucket 2, big bucket pulsator 3, dehydration bucket base 4, middle fountain plate 5 and balance ring 6.

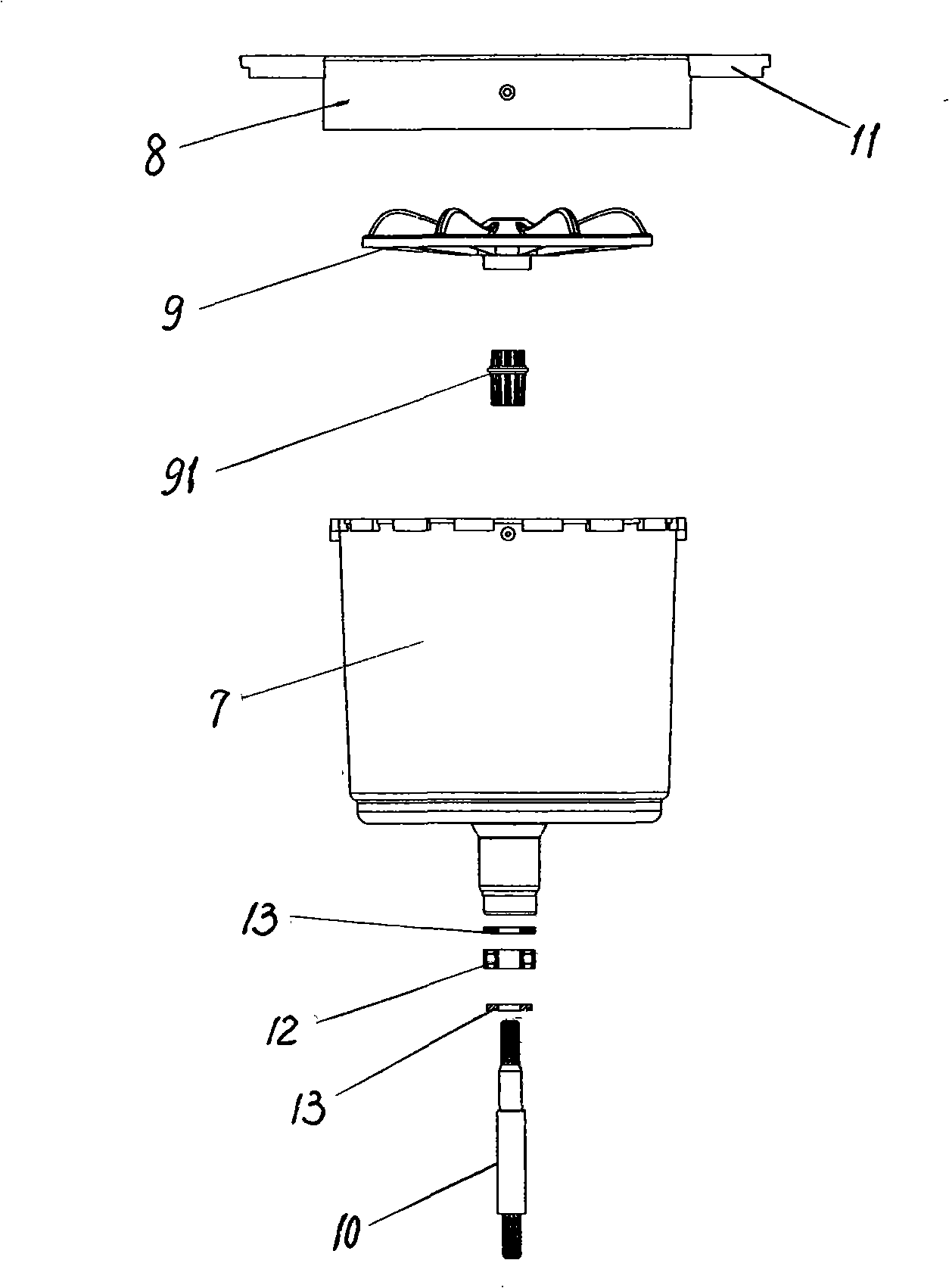

[0022] A small washing and dehydrating bucket 7 is housed in the large washing and dehydrating bucket 2, and the small washing and dehydrating bucket 7 is connected with the large washing and dehydrating bucket 2. Connect a small washing and dehydrating bucket cover 8 on the small washing and dehydrating bucket 7, and be connected by screws or by hooks, or directly welded between the small washing and dehydrating bucket 7 and the small washing and dehydrating bucket cover 8.

[0023] Small bucket impeller 9 is installed at the bottom of little washing and dehydrating bucket 7 insides. A transmission shaft 10 connects the keg pulsator 9 and the large keg pulsator 3, that is, one end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com