Countershaft combination of reverse gear embedded engine

An engine and countershaft technology, applied in the direction of engine components, machines/engines, engine lubrication, etc., can solve the problems of working surface ablation, power consumption, component heating, etc., to achieve good lubrication, reduce frictional resistance, and prevent heat generation. and wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

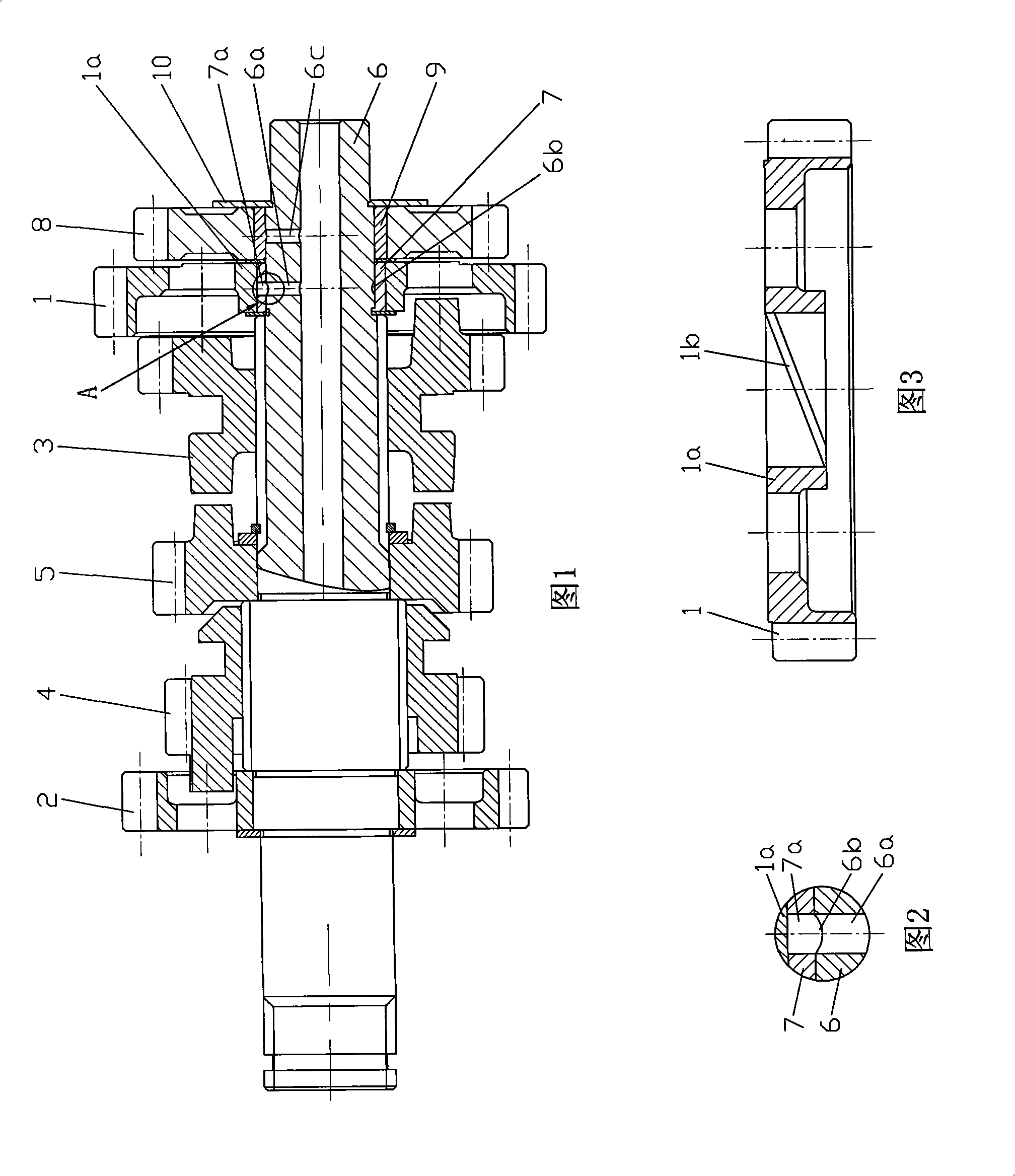

[0012] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0013] As shown in Fig. 1, Fig. 2 and Fig. 3, the present invention is made up of auxiliary shaft 6, first gear 1, second gear 2, third gear 3, reverse gear 5, fourth gear 4, starting gear 8 and axle sleeve 7 and other components. Among them, the third gear 3 and the fourth gear 4 are installed on the countershaft 6 through the key and keyway with clearance fit respectively, and the first gear 1, the second gear 2, the reverse gear 5 and the starting gear 8 are also set on the countershaft 6 , the reverse gear 5 is located between the third gear 3 and the fourth gear 4, the second gear 2 is located outside the fourth gear 4, the first gear 1 is located outside the third gear 3, and the sleeve 7 is located on the first gear 1. Between the central annular boss 1a and the countershaft 6, a countershaft oil hole 6a radially penetrating to its central hole is ope...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap