Open-end spinning rotor for textile machine producing cross-wound packages

A cross-winding bobbin and free-end technology, which is applied to the continuous winding spinning machine, free-end spinning machine, spinning machine, etc., can solve the problem of unfavorable control technology for the positioning of the spinning rotor and achieve the minimum moment of inertia effect of uniformity, load uniformity, and simplified actuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

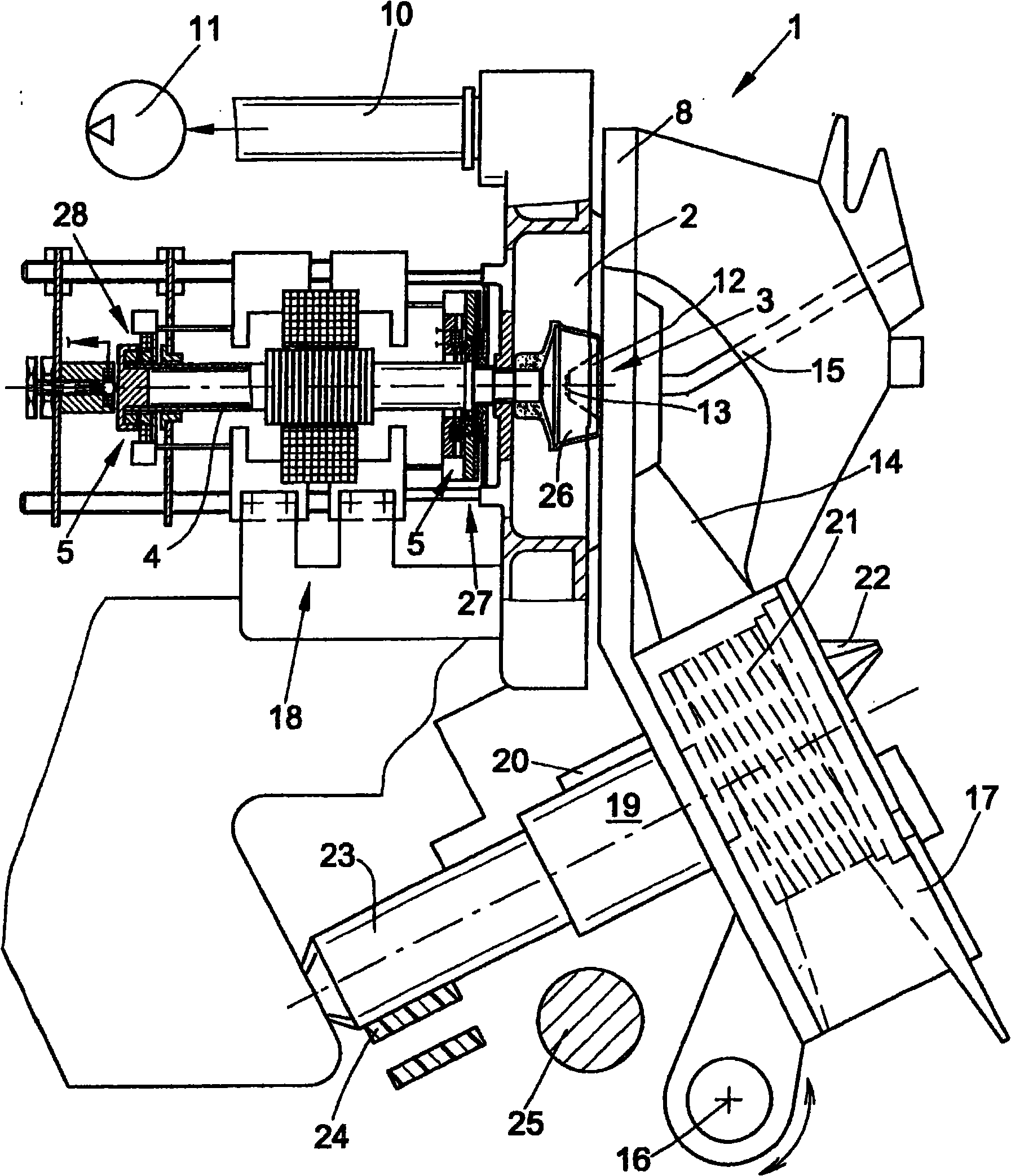

[0024] figure 1 An open-end spinning device 1 is shown with a spinning rotor 3 magnetically mounted and driven by a separate motor.

[0025] An open-end spinning device 1 of this type is known and described in relatively detail, for example, in EP 0 972 868 A2. Each of these open-end spinning devices 1 has a rotor housing 2 in which the spinning rotor 26 of the spinning rotor 3 rotates at high speed.

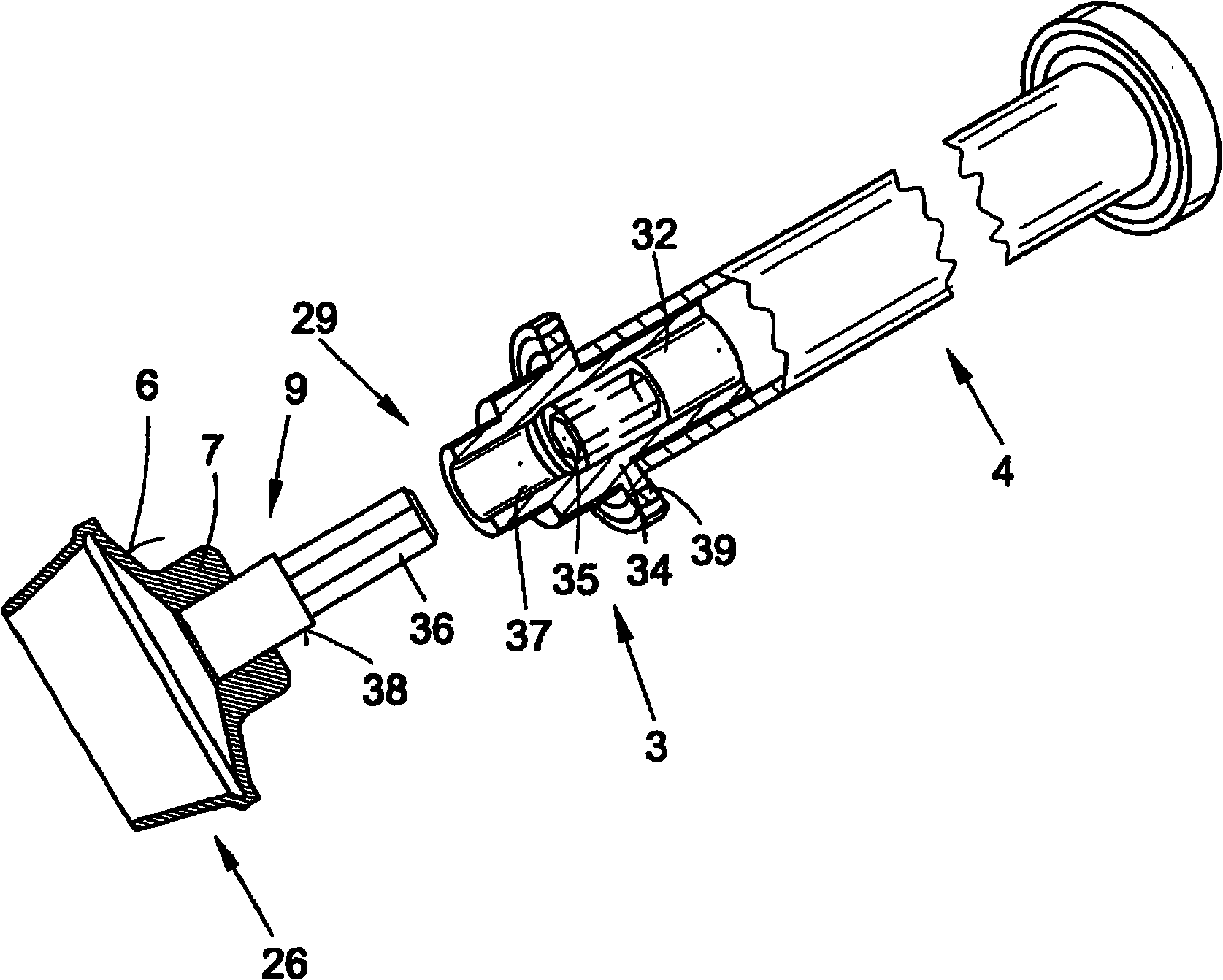

[0026] In the present example, the spinning rotor 3 is preferably driven by a separate electric motor drive 18 and is supported by its rotor shaft 4 on the front bearing point 27 and the rear bearing point 28 of the magnetic bearing structure 5, both bearing points radially The spinning rotor 3 is positioned upward again in the axial direction.

[0027] The rotor hood 2 , which itself is open to the front, is closed during the spinning operation via a pivotably mounted cover part 8 and is connected via a corresponding pneumatic line 10 to a source of negative pressure 11 , whi...

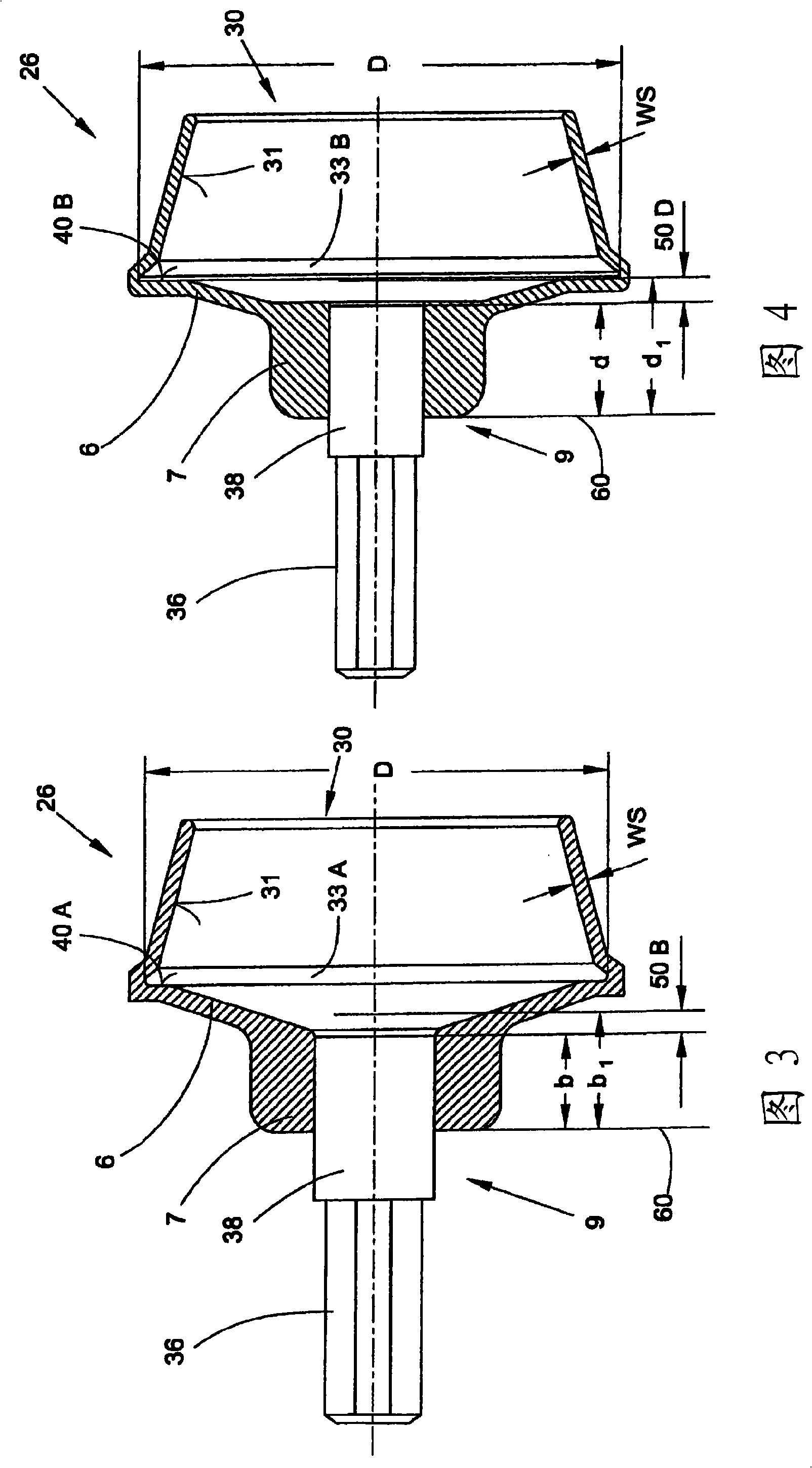

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap