Indexable end-milling insert

A technology of end milling and inserts, which is applied in the field of indexable end milling inserts, can solve the problems of damaging the extruded body, etc., and achieve the effects of long service life, good chip formation, uniform and slow wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

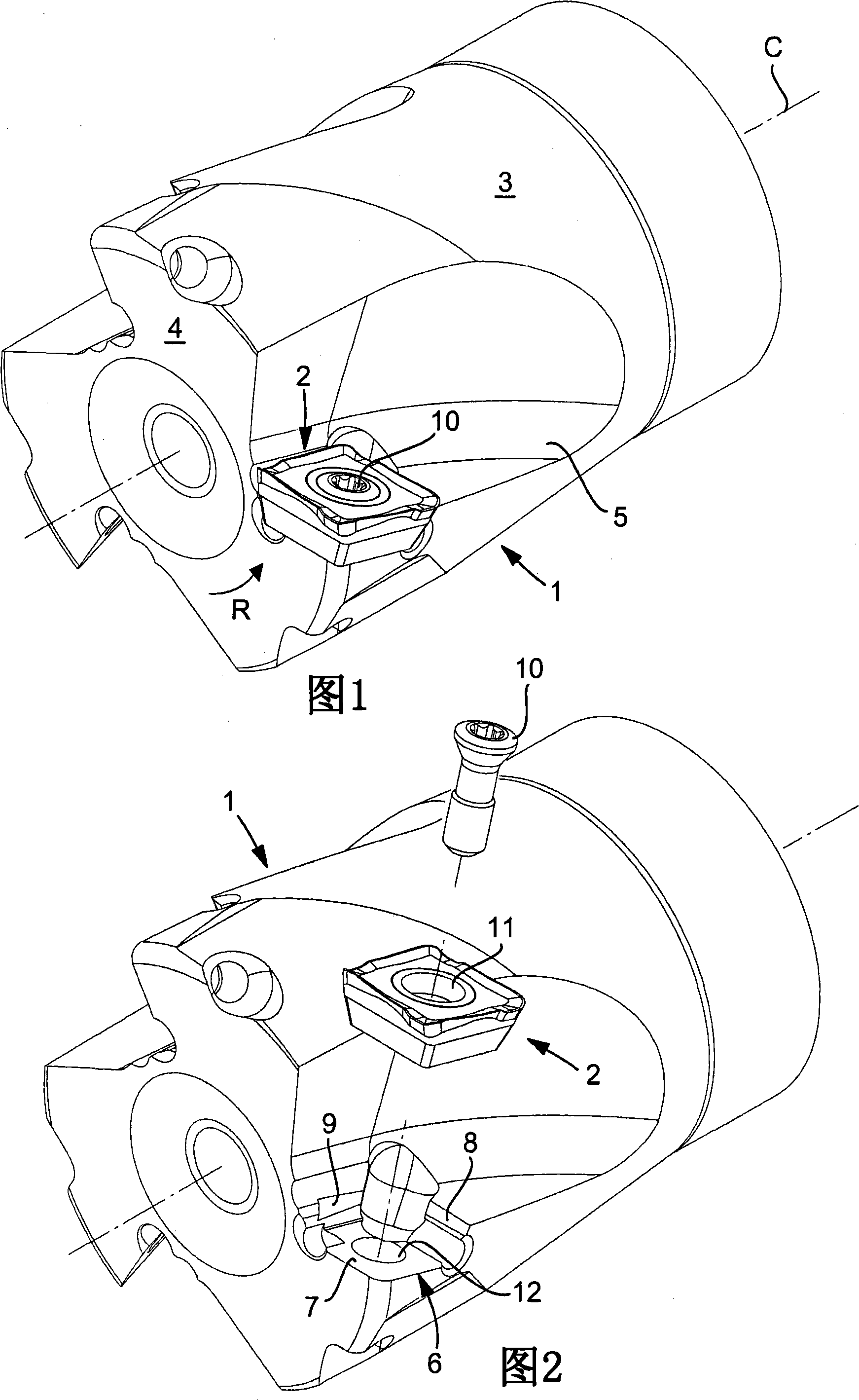

[0029] Hereinafter, preferred embodiments of the cutting insert according to the present invention will be described in detail with reference being made to different drawings. First, the milling body or base body cooperating with the cutting insert will be described in more detail, and then the cutting insert itself will be described.

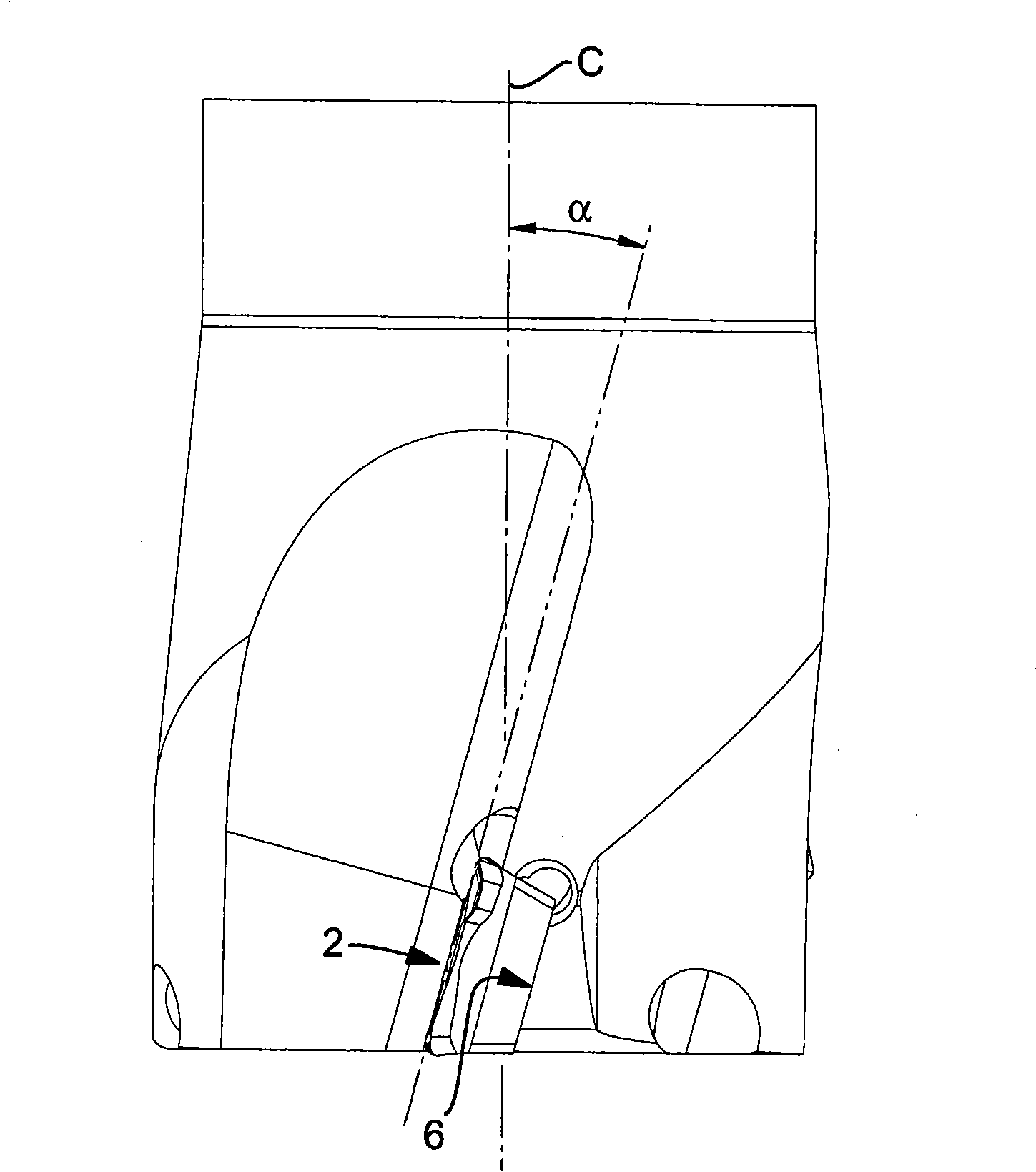

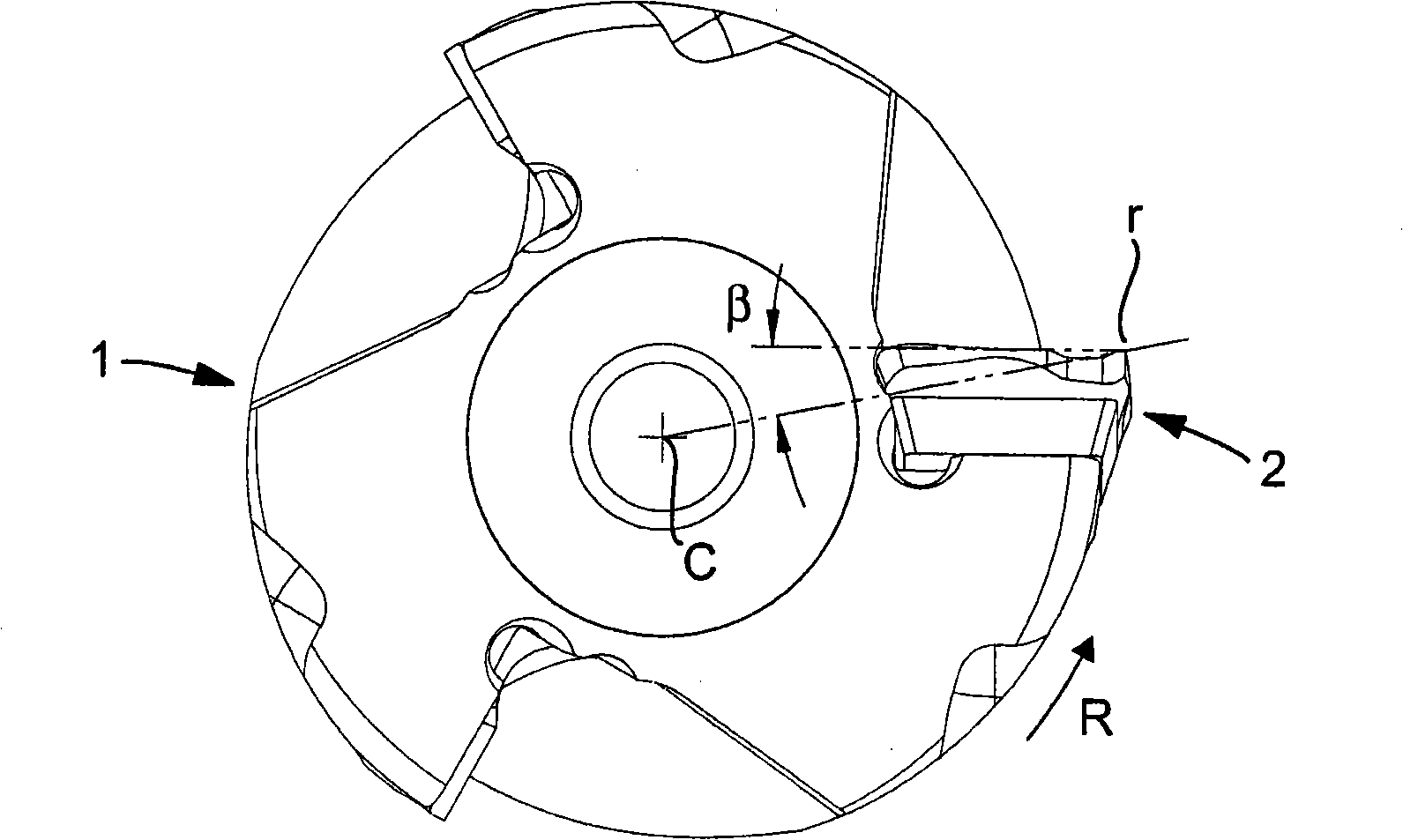

[0030] The assembled milling cutter tool shown in Figures 1-4 comprises a base body 1 and a plurality of cutting inserts 2, only one of which is shown in the respective figure. The basic body or milling cutter body 1 is rotatable about a central axis marked C in a direction of rotation R and has a rotationally symmetrical envelope surface 3 and a front face 4 . A plurality of chip pockets 5 are opened in the envelope surface and the front face, each of said plurality of chip pockets 5 comprising a seat 6 for receiving a cutting insert 2 . In the example, the number of flutes and cutting inserts are three each.

[0031] In this case, the seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com