Plastic-blasting surface decoration firing technique

A technology of plastic spraying and object surface, which is applied in the fields of technology and decorative art for producing decorative surface effects, and can solve the problems of not meeting aesthetic needs and poor aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

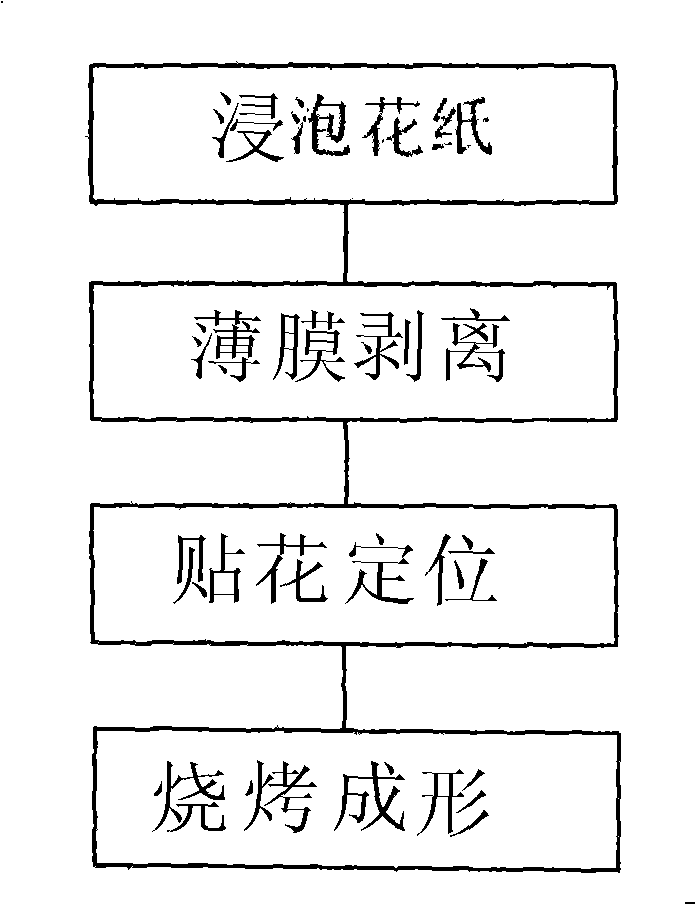

[0016] Put the decal paper into warm water, soak the decal paper for a soak time, it is advisable to separate the decal paper bottom paper from the film sticker with the pattern, usually about 10 seconds.

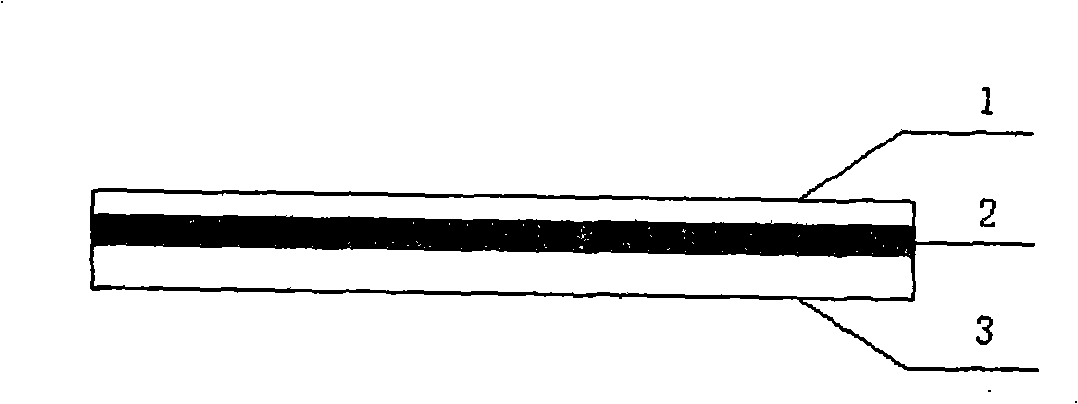

[0017] Separate the bottom paper of flower paper from the film sticker with pattern, stick the separated side of the film sticker and the bottom paper on the predetermined position on the surface of the object after spraying, squeeze out the air to make it closely adhere to the surface of the object Combine, and then separate the sticker surface film from the pattern film.

[0018] Put the processed object into the barbecue oven and grill. The processing temperature and processing time required by different plastic spraying materials are slightly different. Generally, the processing temperature is required to be between 180°C and 220°C, and the processing time is between 15 and 20 minutes.

[0019] After roasting, the color pattern film is fixed on the surface of the spraye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com