Automobile lower body structure

A body and automobile technology, applied in load-bearing body structures, superstructures, vehicle components, etc., can solve the problems of occupant living space compression, insufficient vehicle rigidity, and poor NVH performance of the vehicle, so as to improve the noise problem and increase the carrying capacity ability, the effect of improving the bending stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

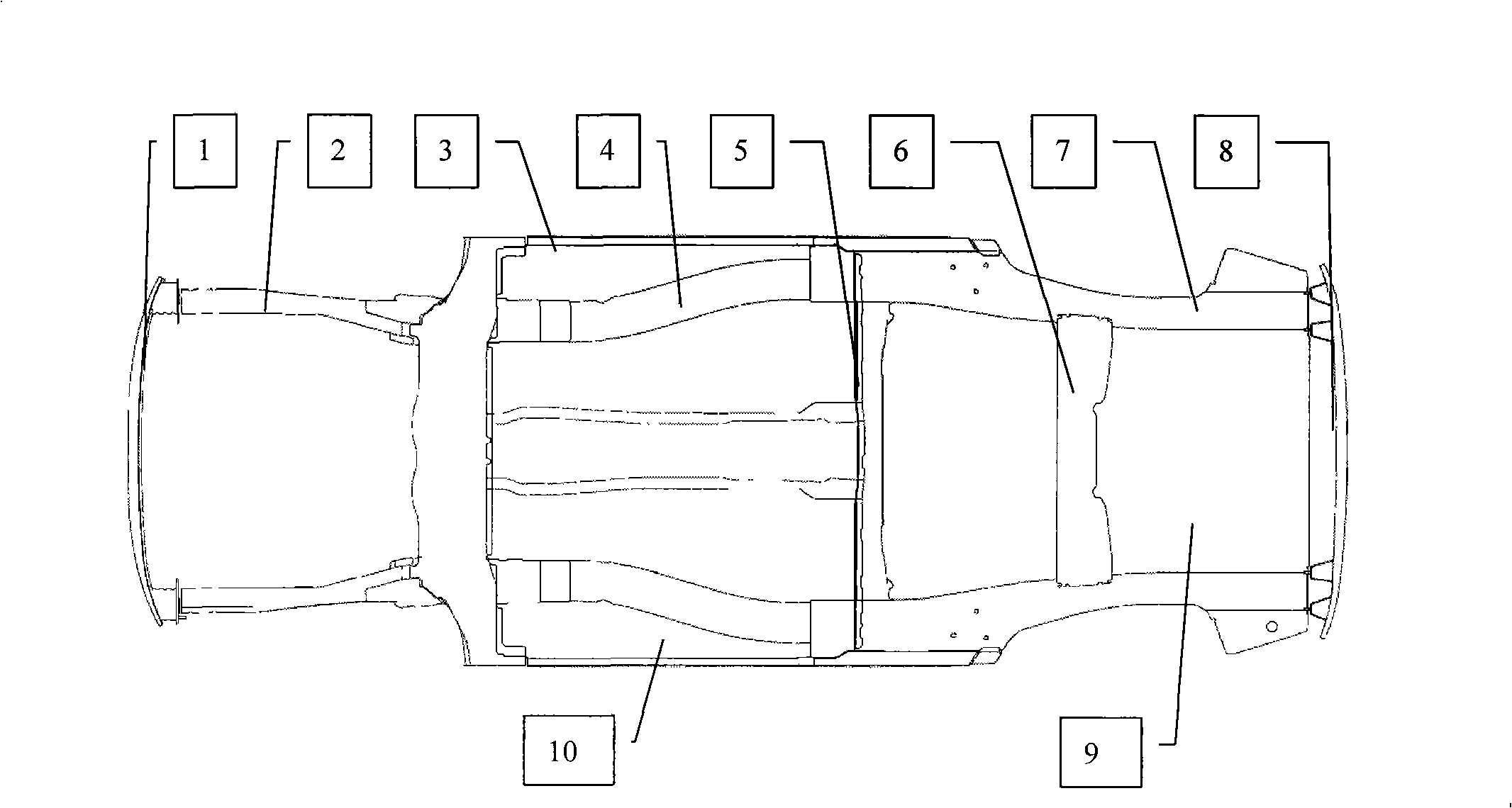

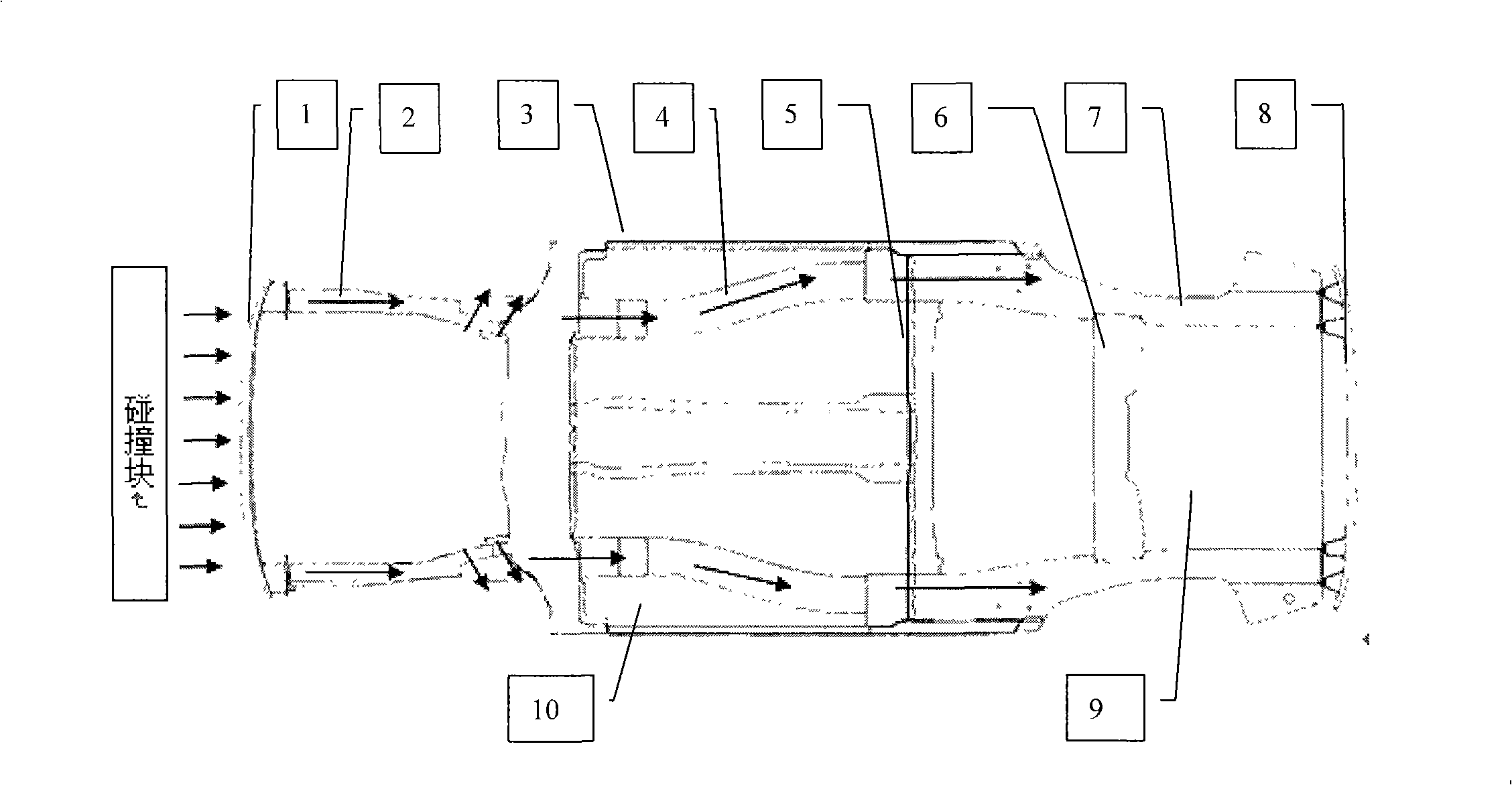

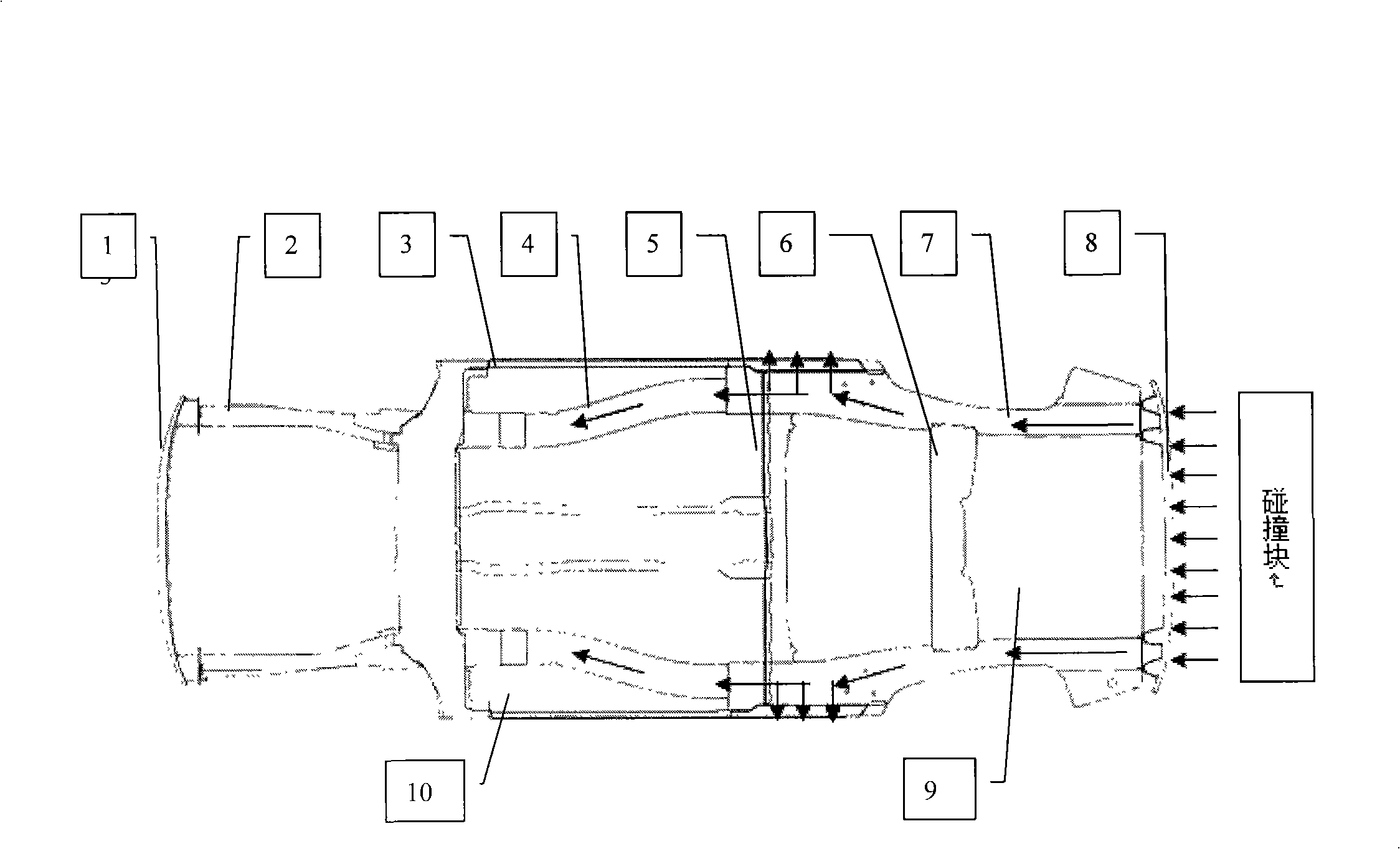

[0023] refer to figure 1 Schematic diagram of the vehicle lower body structure of the present invention, in a preferred embodiment of the present invention, it can be seen that the automobile lower body structure of the present invention comprises a front bumper beam 1, a front longitudinal beam 2, a side sill 3, and a front floor lower longitudinal beam 4. Rear floor front beam 5, rear floor center beam 6, rear longitudinal beam 7, rear bumper beam 8, rear floor 9, front floor 10. Usually, the collision energy is transmitted through the lower frame of the vehicle body. The important connection in this design is that the front bumper beam 1 is connected with the front longitudinal beam 2 through bolts, the front longitudinal beam 2 is welded with the lower longitudinal beam 4 of the front floor, and the lower longitudinal beam 4 is connected with the lower longitudinal beam of the front floor. The rear longitudinal beam 7 is welded, and the rear longitudinal beam 7 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com