Polyethylene resin composition for injection molding container cover

A polyethylene resin, injection molding technology, applied in applications, household components, household appliances, etc., can solve problems such as widening molecular weight distribution, difficulty in injection molding, and inability to cut bridges, so as to maintain stress crack resistance, Effect of improving injection moldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0104]

[0105] A Ti-based catalyst prepared by a solvent extraction method is used as a solid catalyst component. Its production method is as follows.

[0106] The inside of a 1-liter three-necked flask equipped with a stirrer and a cooler is fully replaced with nitrogen, and then 250 ml of dry hexane, 11.4 g of anhydrous magnesium chloride and 110 ml of n-butanol that have been pulverized in a 3-liter vibration mill for 1 hour are added. , heated at 68°C for 2 hours to obtain a homogeneous solution (1a). After cooling this solution (1a) to room temperature, 8 g of methylpolysiloxane having a kinematic viscosity of 25 cSt at 25° C. was added thereto, followed by stirring for 1 hour to obtain a uniform solution (1b). After the solution (1b) was cooled with water, 50 ml of titanium tetrachloride and 50 ml of dry hexane were added dropwise thereto over 1 hour using a dropping funnel to prepare a solution (1c). The solution (1c) was homogeneous, and no complex compound of the...

Embodiment 2~3

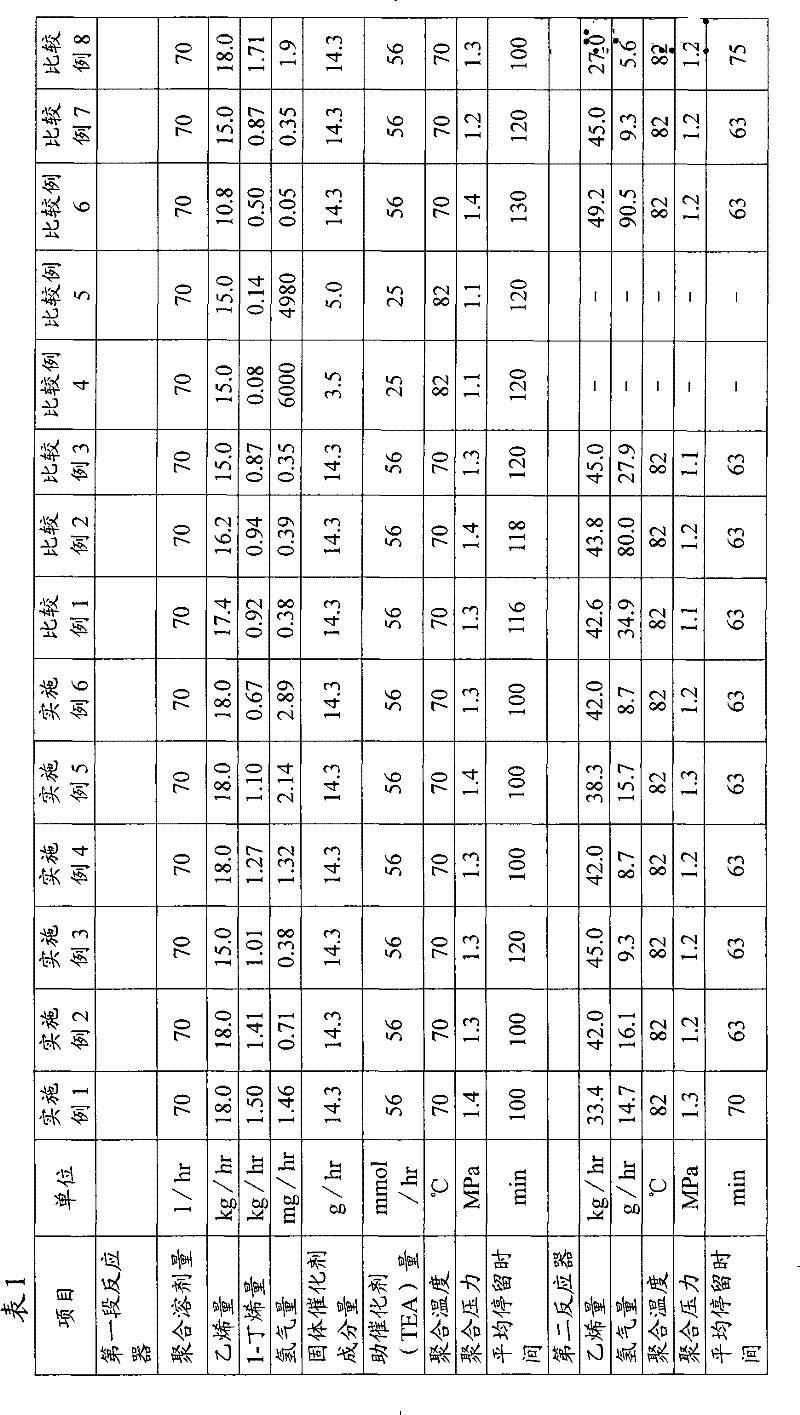

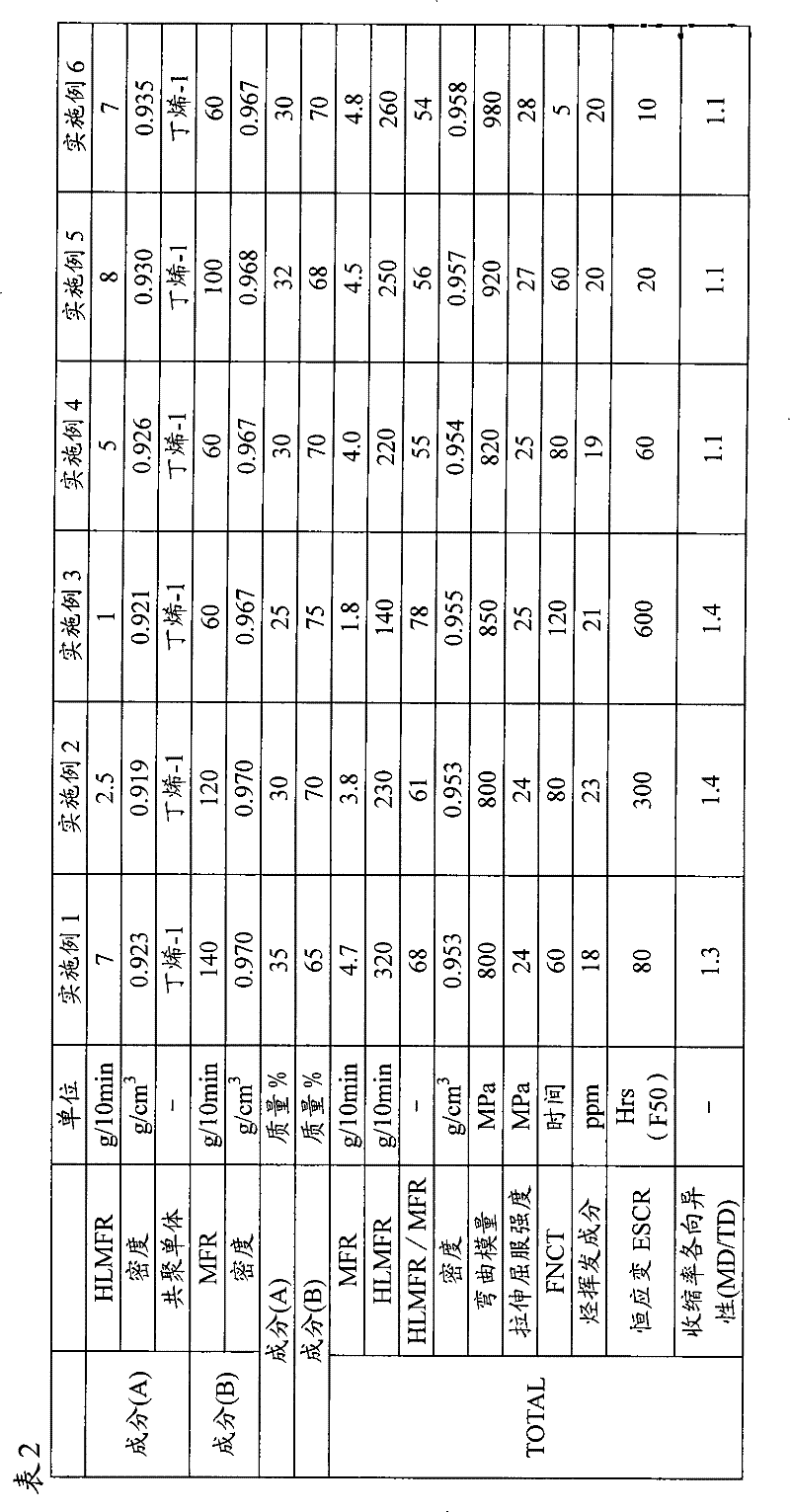

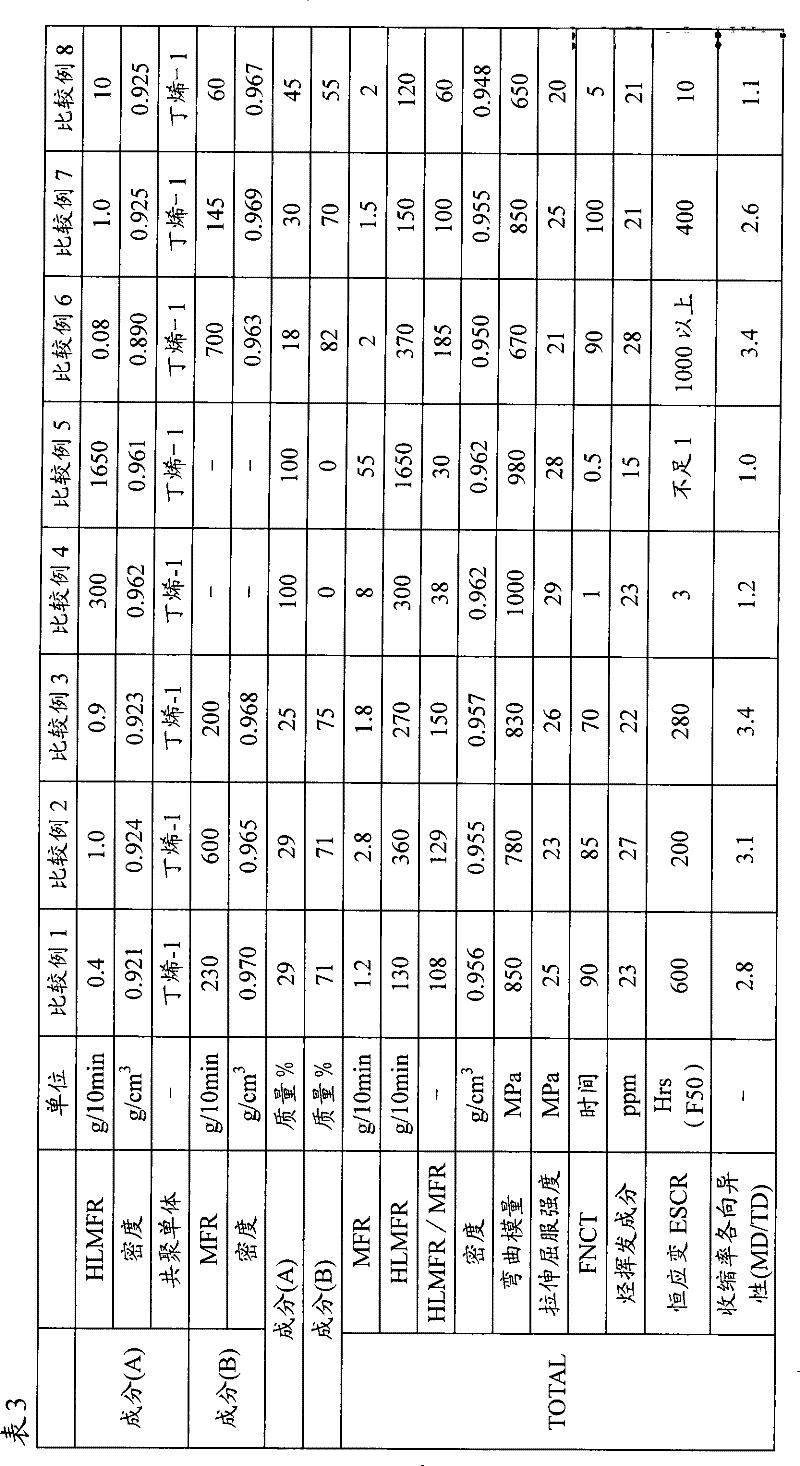

[0117] Except the conditions shown in Table 1, it carried out similarly to Example 1. Table 2 shows the evaluation results of the obtained polymer. The obtained polymer was excellent in mechanical properties such as tensile yield strength, flexural modulus, and FNCT, and had an appropriate shrinkage anisotropy (MD / TD).

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com