Light carcass for cast-in-situ concrete stuffing

A cast-in-place concrete, light-weight technology, applied in the direction of structural elements, building components, building reinforcements, etc., can solve the problems of inconvenient layout, affecting construction efficiency, affecting floor construction quality, etc., achieve large anchoring force, meet the resistance Floating positioning, the effect of convenient application operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

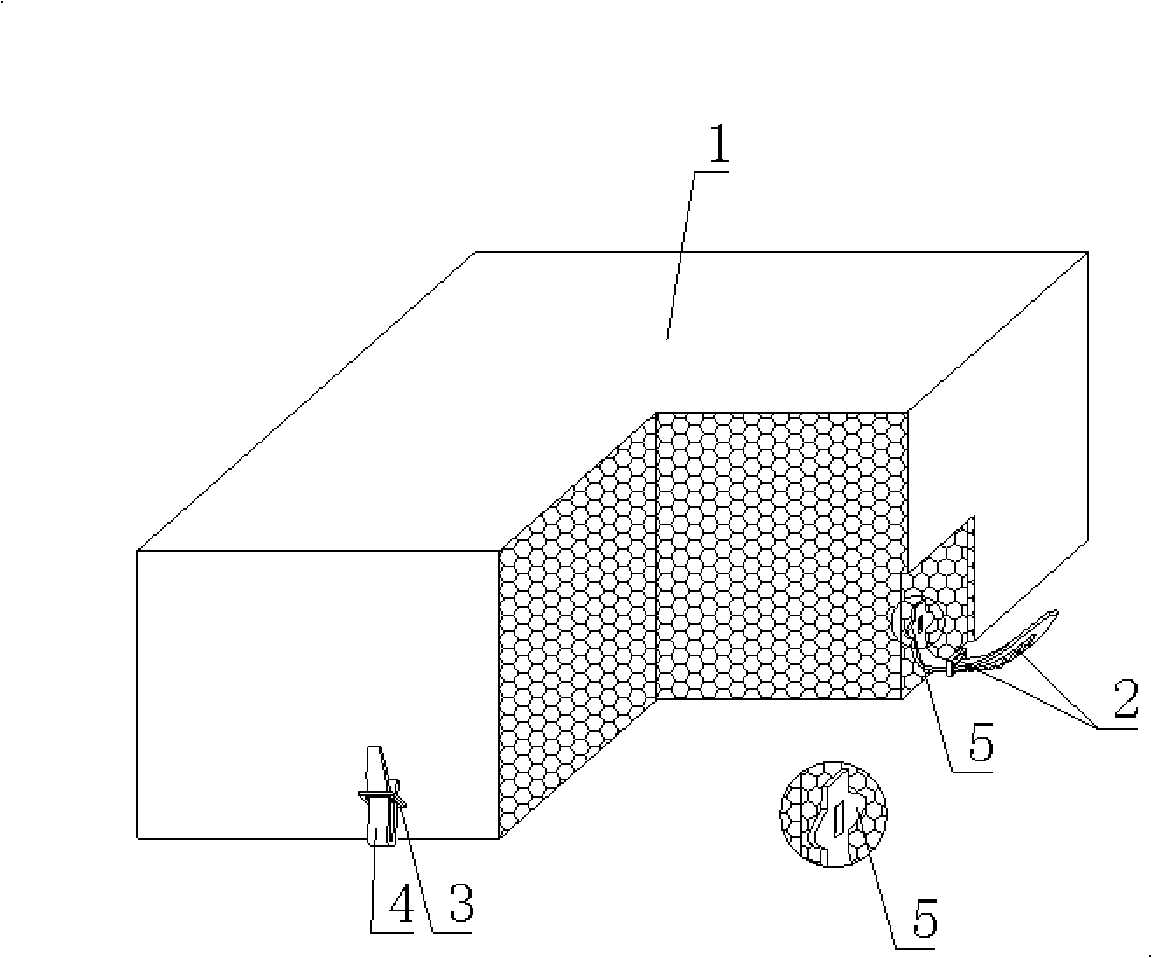

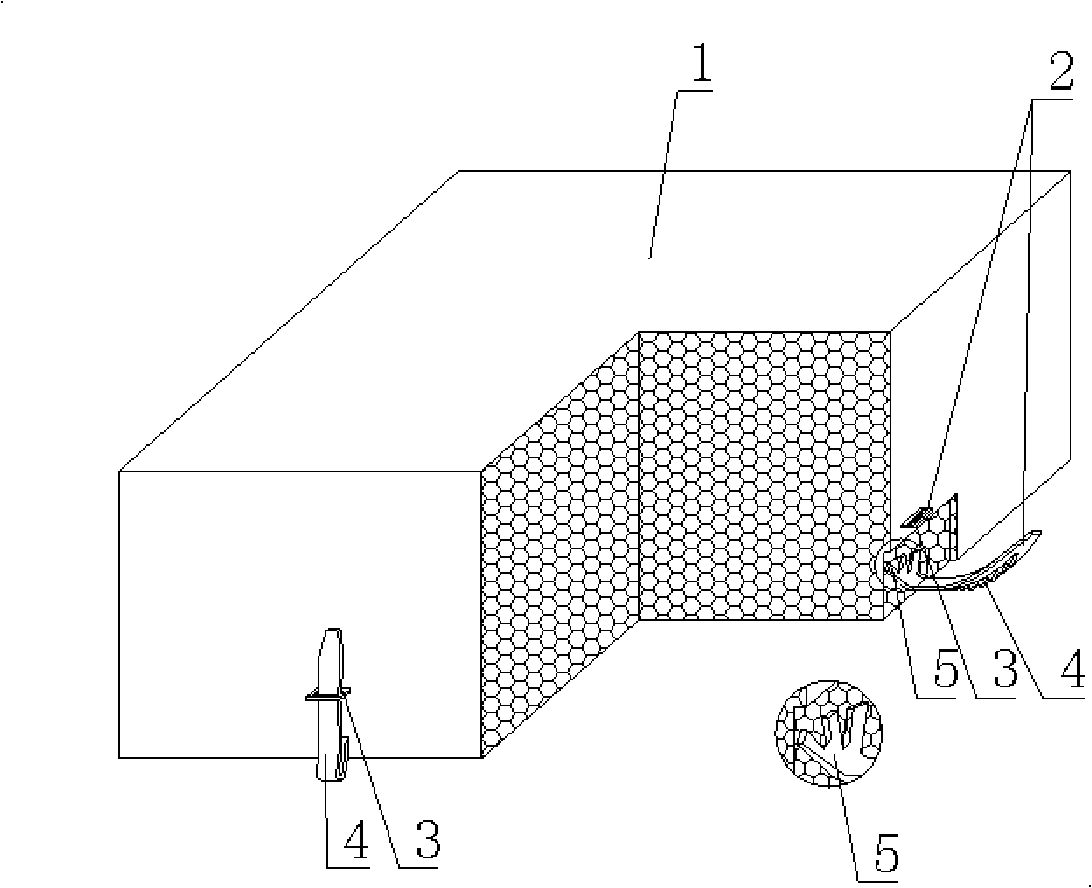

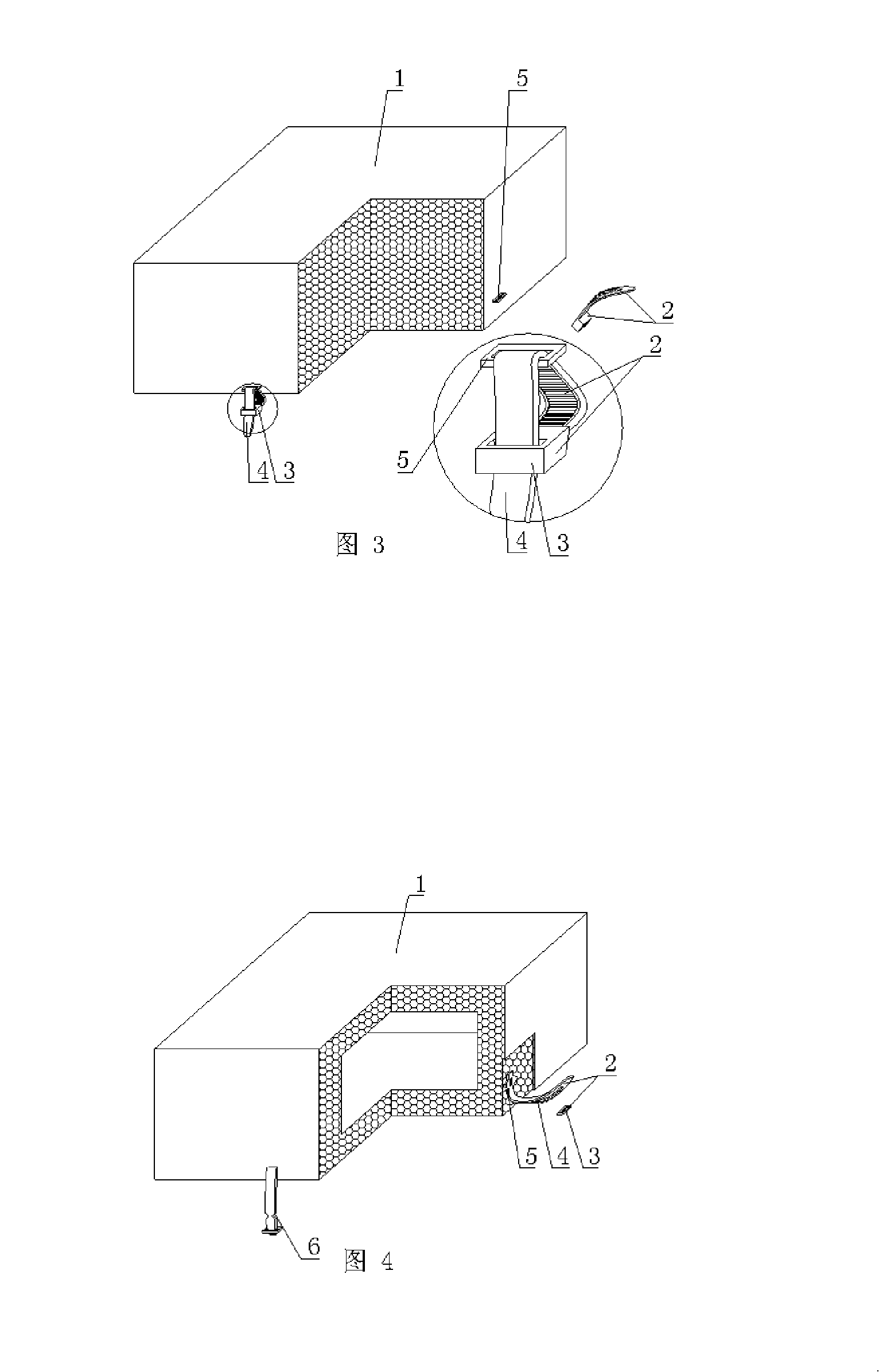

[0058] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0059] As shown in the accompanying drawings, the present invention includes a lightweight carcass 1 with a bulk density lighter than that of concrete, and is characterized in that the lightweight carcass 1 is provided with a locking member 2, and the locking member 2 includes a self-locking hole 3 and Self-locking strips or strips 4, the locking member 2 is anchored in the lightweight carcass 1 by the anchoring member 5 or the locking member 2 is connected with the anchoring member 5 anchored in the lightweight carcass 1, and the self-locking hole 3 is movable on the self-locking strip or strip 4, and the locking part 2 passes through the lightweight carcass 1, and stretches out the lightweight carcass 1 to expose. In each drawing, 1 is a lightweight carcass, 2 is a locking member, 3 is a self-locking hole, 4 is a self-locking strip or strip, and 5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com