Beam type oil pumping machine crank guard rail

A beam pumping unit and pumping unit technology, applied in the direction of fences, production fluids, boreholes/well components, etc., can solve problems affecting oil field safety production, crank injury or death of people, crank injury or death and other problems, to achieve the effect of preventing accidents caused by cranks, simple structure, and easy to carry when folded and assembled.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to further disclose the technical solutions of the present invention, the following will be described in detail through examples in conjunction with the accompanying drawings:

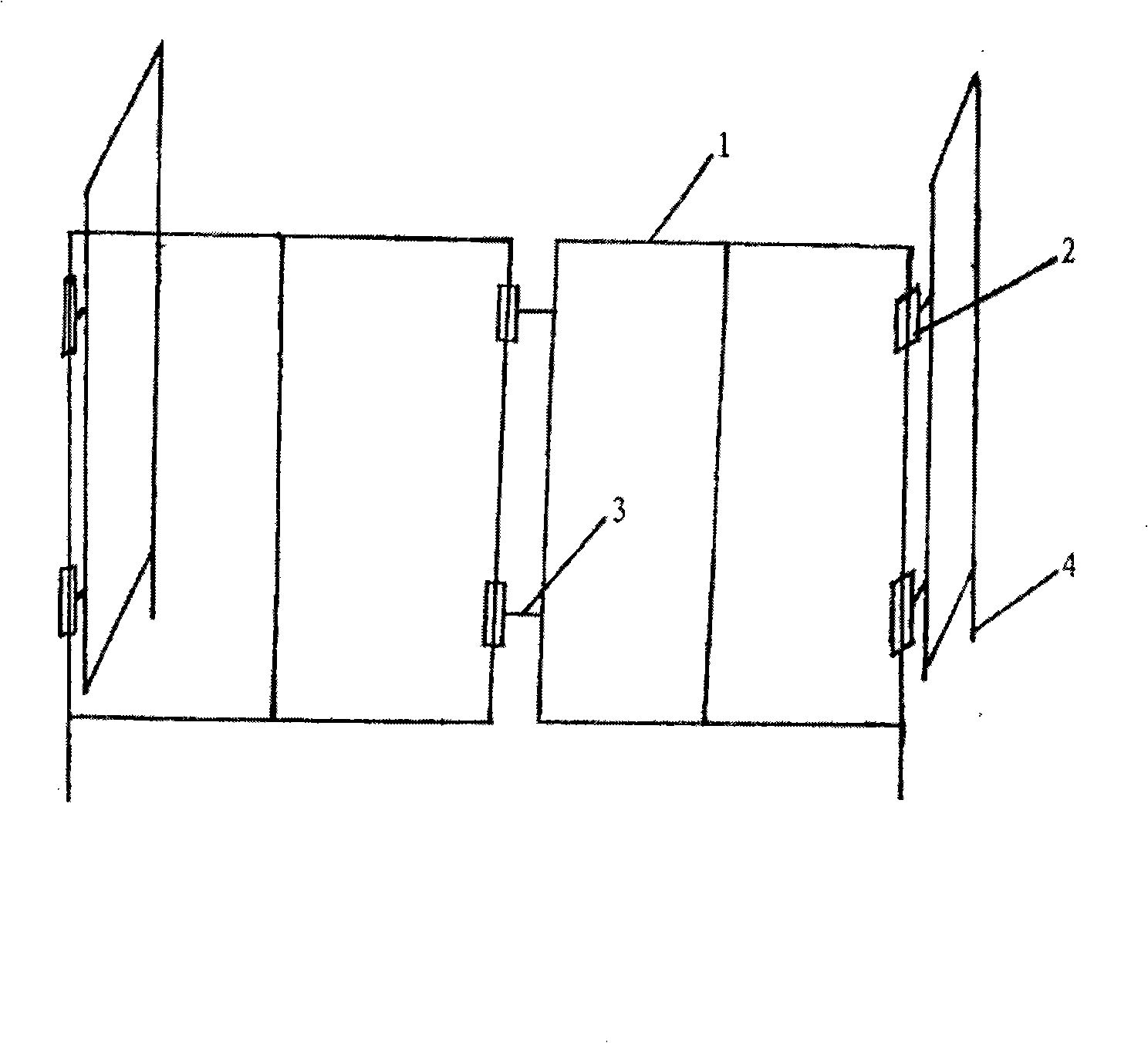

[0010] The present invention is made up of steel bar frame 1 or plastic frame, is characterized in that two sets of steel bar frames or multiple sets of steel bar frames or multiple sets of plastic frames are arranged on the front of the crank guardrail, and a set of steel bar frames or plastic frames are arranged on both sides, steel bar frames or plastic frames. The frame is connected with the steel bar frame or the plastic frame with the pipe sleeve 2 and the support 3, and the outer frame of each steel bar frame or plastic frame is provided with a support leg 4: the support leg is fixed on the cement base of the pumping unit.

[0011] The invention can be folded together, and the transportation is convenient. Open the guardrail at the site, insert the outriggers into the pre-drilled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com