Thin fan structure

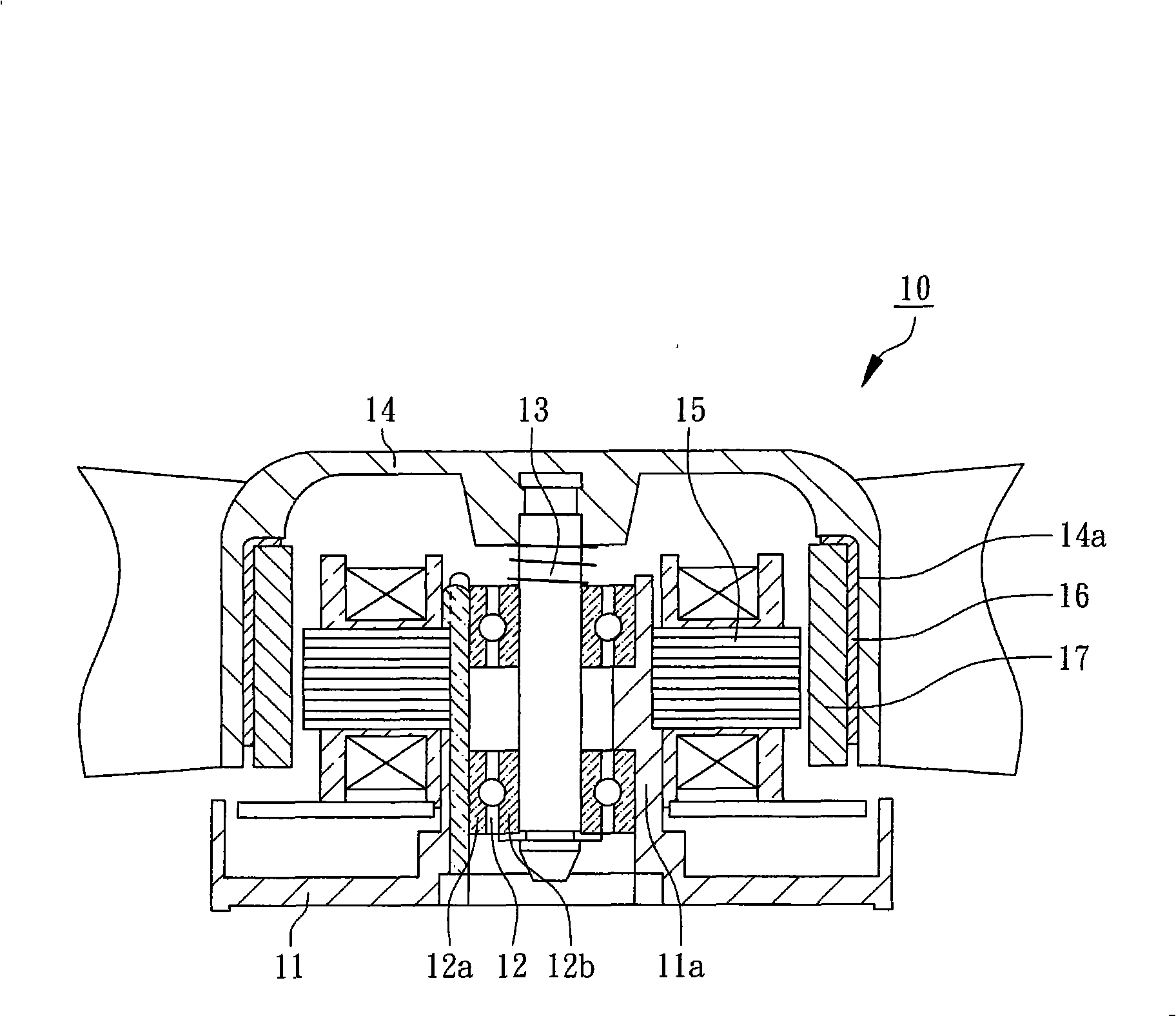

A thin fan and structure technology, which is applied to the components of pumping devices for elastic fluids, non-variable displacement pumps, pump devices, etc. Cut structure, weight and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, characteristics and effects of the thin fan structure proposed according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. Details are as follows.

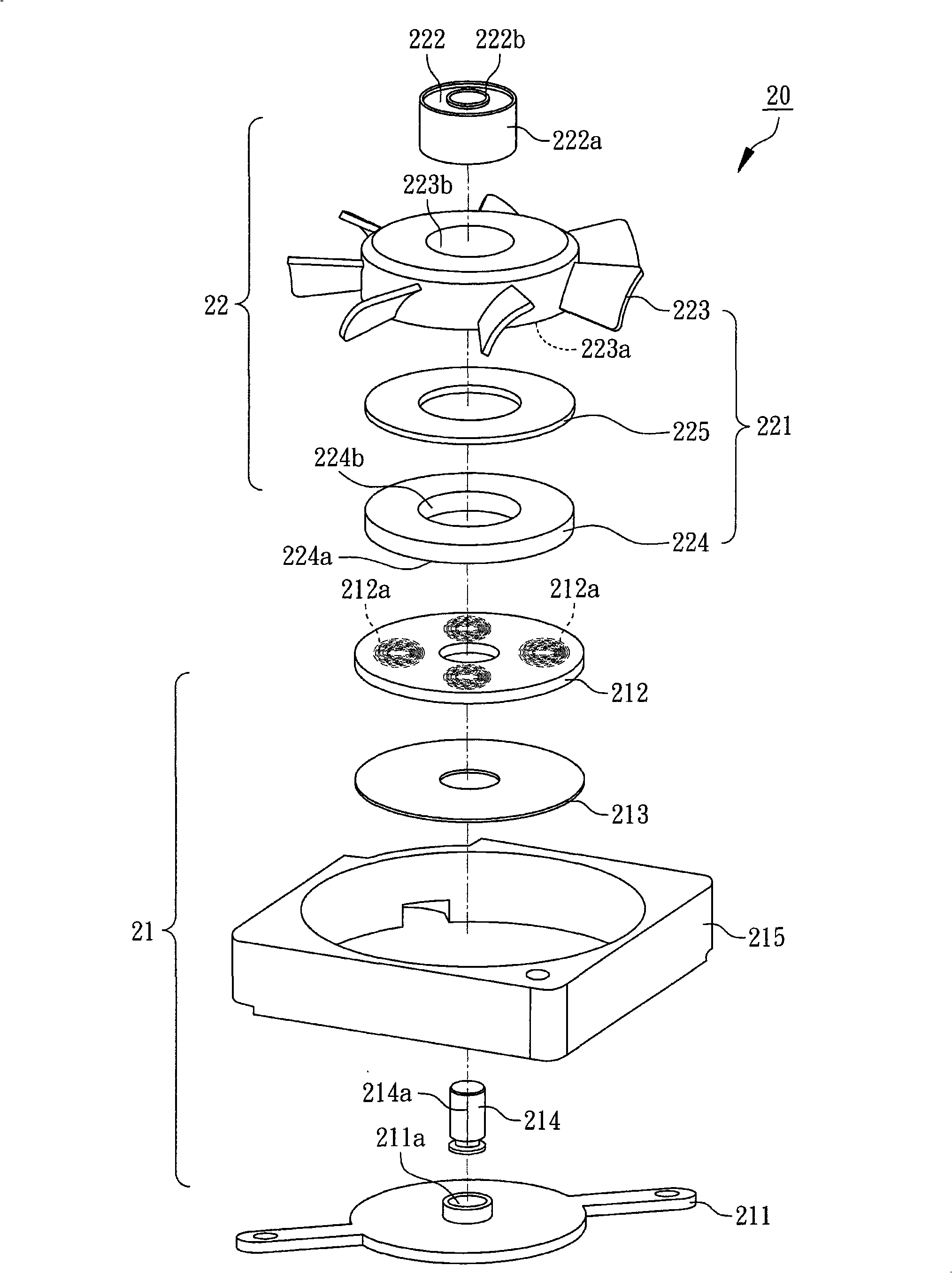

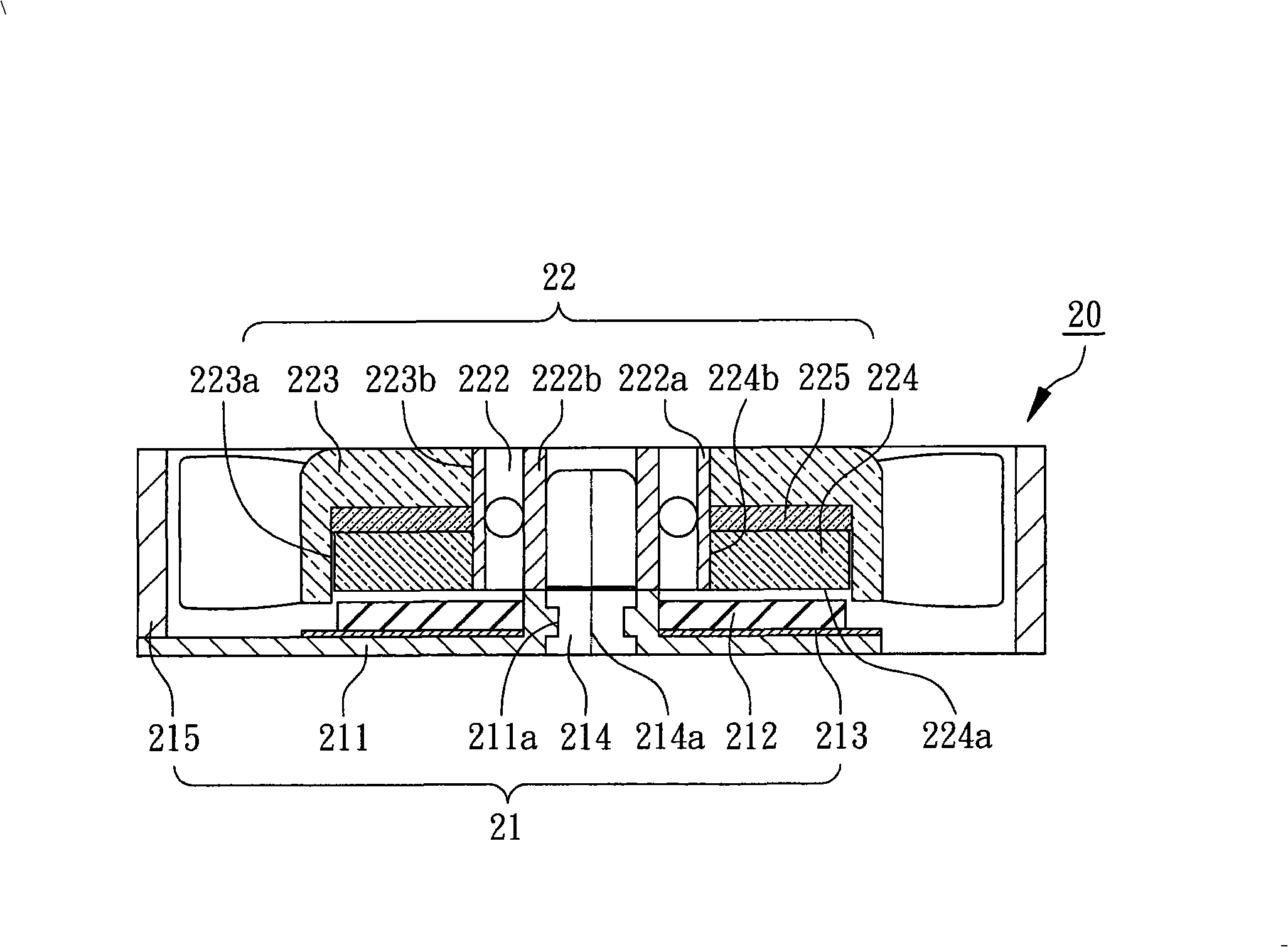

[0045] see figure 2 and 3The figure shows the first preferred embodiment of the present invention. A thin fan structure 20 includes a driving assembly 21 and a rotating assembly 22. In this embodiment, the driving assembly 21 includes a base 211 and a coil Circuit board 212, an insulating sheet 213 and an axis 214, the material of the base 211 can be metal, preferably, the material of the base 211 is ferrous metal, and the coil circuit board 212 is arranged on the base 211 , the coil circuit board 212 has an embedded coil winding 212a, the embedded coil winding 212a is used to d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com