Automatic control method of industry vehicle fork operation

A technology of industrial vehicles and forks, which is applied in the field of industrial vehicle control, can solve the problems that the safety of the control mode needs to be improved, and achieve the effect of reducing the difficulty of setting and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The following describes in detail a process for a stacker truck to use the present invention to pre-set fork action programs and data, and to control the forks to perform automatic access to target goods.

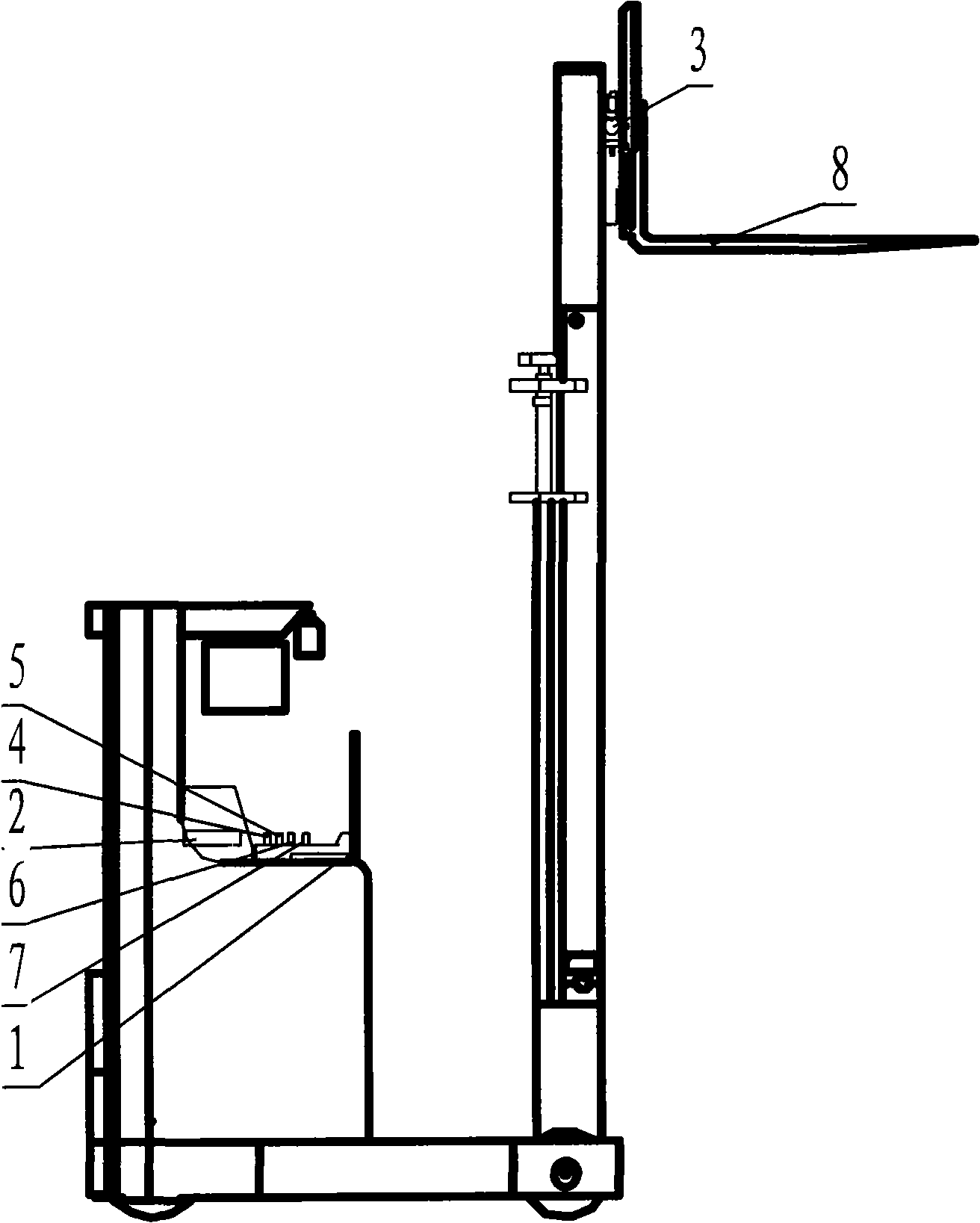

[0012] like figure 1 As shown in the figure, like a common high-lift stacker, the fork 8 of the stacker can perform four actions, such as up and down, left and right side shift, fork surface inclination, and forward and backward. The control switches are directly controlled, including the lift switch 4 , the side shift switch 5 , the tilt switch 6 and the forward and backward switch 7 . Each control switch has three state settings: forward action, reverse action and zero stop (for example, in the up and down lifting action, the upward action is forward action, and the downward action is reverse action), and the joystick control switch With automatic zero-recovery feature. When the fork 8 is in a forward action state or a reverse action state, a corresponding graphi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com