Cantilever-type tower crane foundation structure and construction method thereof

A technology of tower crane foundation and cantilever type, which is applied in the direction of foundation structure engineering and construction, which can solve the problems of unsatisfactory surroundings and limited plane position of tower crane foundation, and achieve the effects of reducing the structure size, reducing the difficulty of setting, and protecting corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

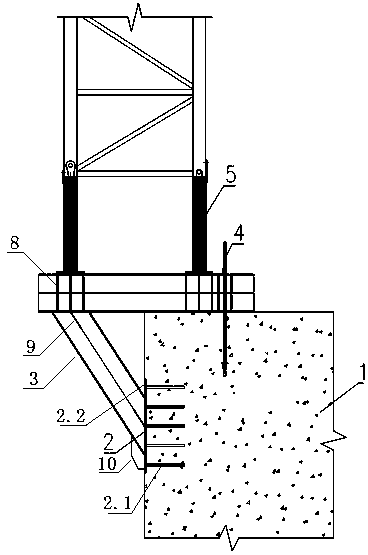

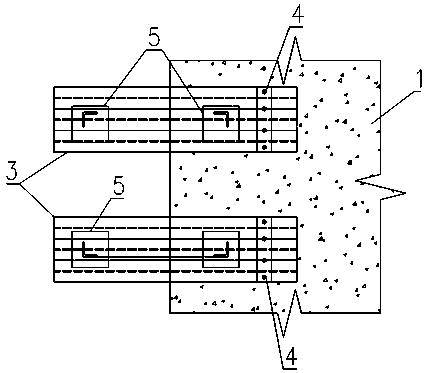

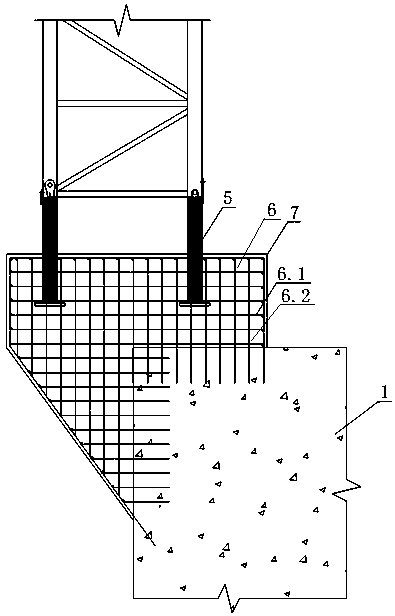

[0035] The cantilever type tower crane basic structure provided by the invention, such as figure 1 , figure 2 As shown, it at least includes a cap 1, a shaped steel corbel 3 and a tower crane embedded foundation 5, and the side of the cap 1 is provided with a plurality of pre-embedded steel plates 2, and the profiled steel corbel 3 is provided with two groups, and each group of shaped steel The corbels 3 independently carry the two feet of the pre-embedded foundation 5 of the tower crane. One end of each set of shaped steel corbels 3 is fixed on the platform 1, and the other end of the shaped steel corbels 3 is suspended in the air. The shaped steel corbels 3 are fixed on One end of the bearing platform 1 is counter-pressed by prestressed steel bar 4;

[0036] In the present invention, steel is used as the cantilever corbel structure, and the installation position of the tower crane is extended from the range of reinforced concrete to outside the range of reinforced concrete...

Embodiment approach 2

[0038] Embodiment 2 of the present invention relates to a cantilever type tower crane foundation structure, such as figure 1 As shown, it includes a cap 1, a section steel corbel 3 and a tower crane embedded foundation 5, the side of the cap 1 is provided with a plurality of pre-embedded steel plates 2, and the section steel corbel 3 is provided with two groups, each group of section steel The corbel 3 independently carries the two foundation feet of the embedded foundation 5 of the tower crane. Further, the profiled steel corbel 3 is composed of horizontal braces and diagonal braces, and is welded as a whole with the embedded steel plate 2. Preferably, the One end of the horizontal brace is fixed on the bearing platform 1, and the prestressed steel bar 4 is used for back pressure; the other end of the horizontal brace is suspended, and a plurality of vertical stiffening plates-8 are arranged inside the horizontal brace; One end of the brace is connected to the suspended end o...

Embodiment approach 3

[0042] Embodiment 3 of the present invention relates to a cantilevered tower crane foundation structure, which includes a cap 1, a steel corbel 3 and a pre-embedded tower crane foundation 5, the side of the cap 1 is provided with a plurality of pre-embedded steel plates 2, the There are two groups of shaped steel corbels 3, each group of shaped steel corbels 3 independently bears two feet of the pre-buried foundation 5 of the tower crane, one end of each set of shaped steel corbels 3 is fixed on the bearing platform 1, and the other end of the shaped steel corbels 3 One end is suspended in the air, and the suspended end of the shaped steel corbel 3 is connected to the embedded steel plate 2; the other end of the shaped steel corbel 3 fixed on the platform 1 is back-pressed by prestressed steel bar 4, such as figure 2As shown, further, each group of shaped steel corbels 3 is fixed on the bearing platform 1 through at least four prestressed steel bars 4, the prestressed steel ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com