Sensor system, including a plurality of individual and separate sensor elements

A sensor device and sensor element technology, which is applied in the direction of transmitting sensing components, measuring devices, and microstructure devices using electric/magnetic devices, can solve the problems of high development cost, difficulty in using size-sensitive applications, and high overhead. The effect of reducing overhead

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

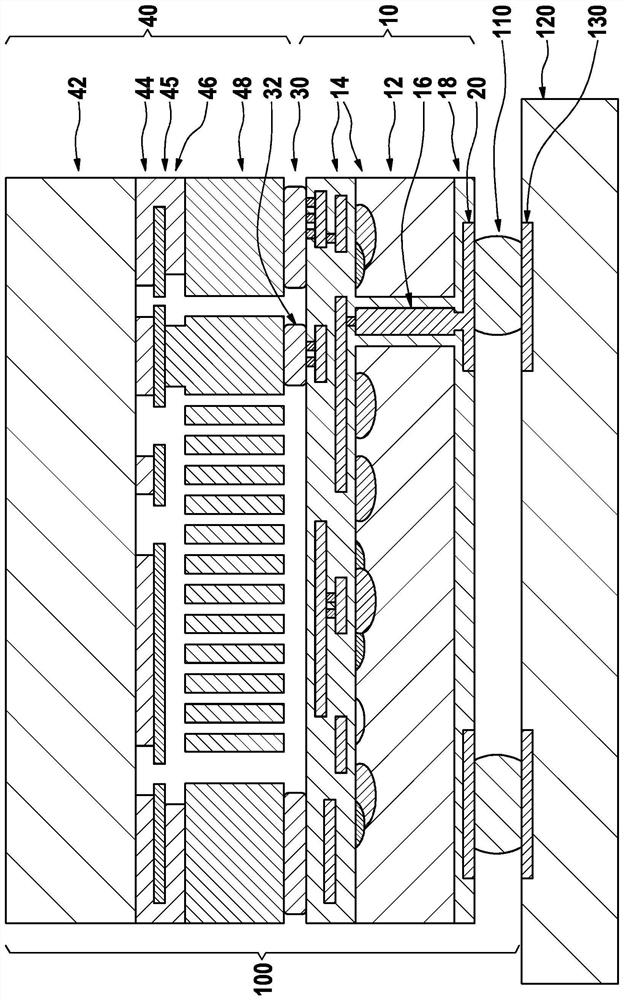

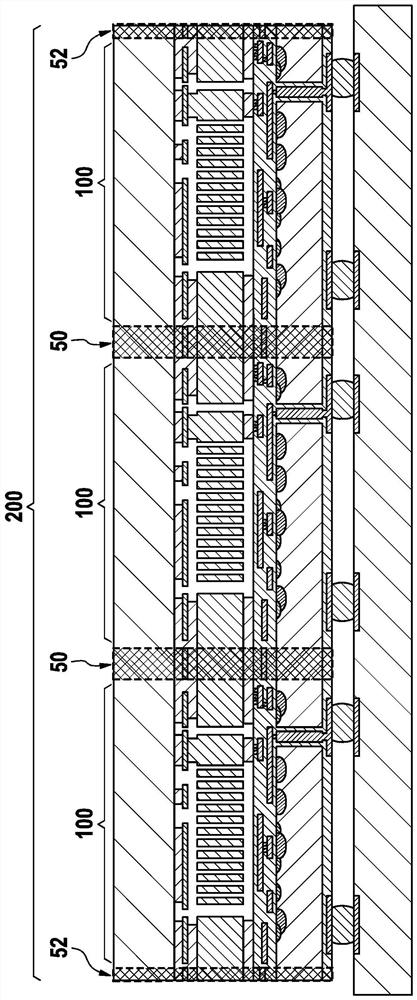

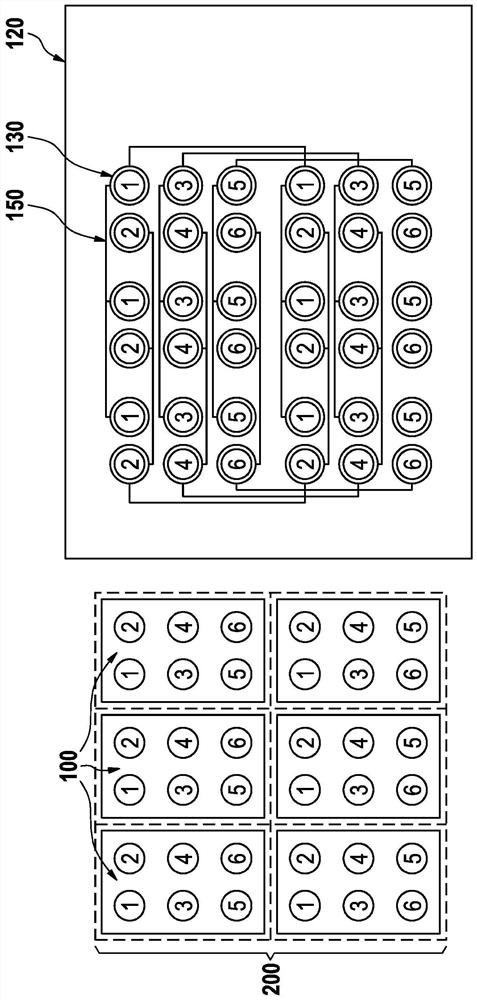

[0021] As an example implementation, in figure 1 A sensor device 200 according to the invention is shown in a schematic side view (cf. figure 2 ) A cross-sectional view of a single and separated sensor element 100. therefore, figure 1The basic configuration of an individual sensor element according to the invention is shown, wherein the sensor device 200 has a plurality of such sensor elements 100 or individual sensor elements 100 , in particular a plurality of such sensor elements 100 of the same type or identical design. . In particular, the individual sensor element 100 is realized as a so-called ASICap-MEMS component 100 , ie it has a first substrate 42 with a micromechanical sensor structure and a second substrate 12 with an associated evaluation circuit 14 , This first substrate is formed or realized in (or mainly in) the micromechanical functional layer 48 . The substrates 42, 12 have a main plane of extension arranged substantially parallel to each other, wherein ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com