Structure for sensing wafer, wafer-class sensing assembling structure and method for producing same

A manufacturing method and a technology for sensing chips, which are applied in radiation control devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as inability to actuate, deteriorate, and change, and achieve the effect of reducing the size of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

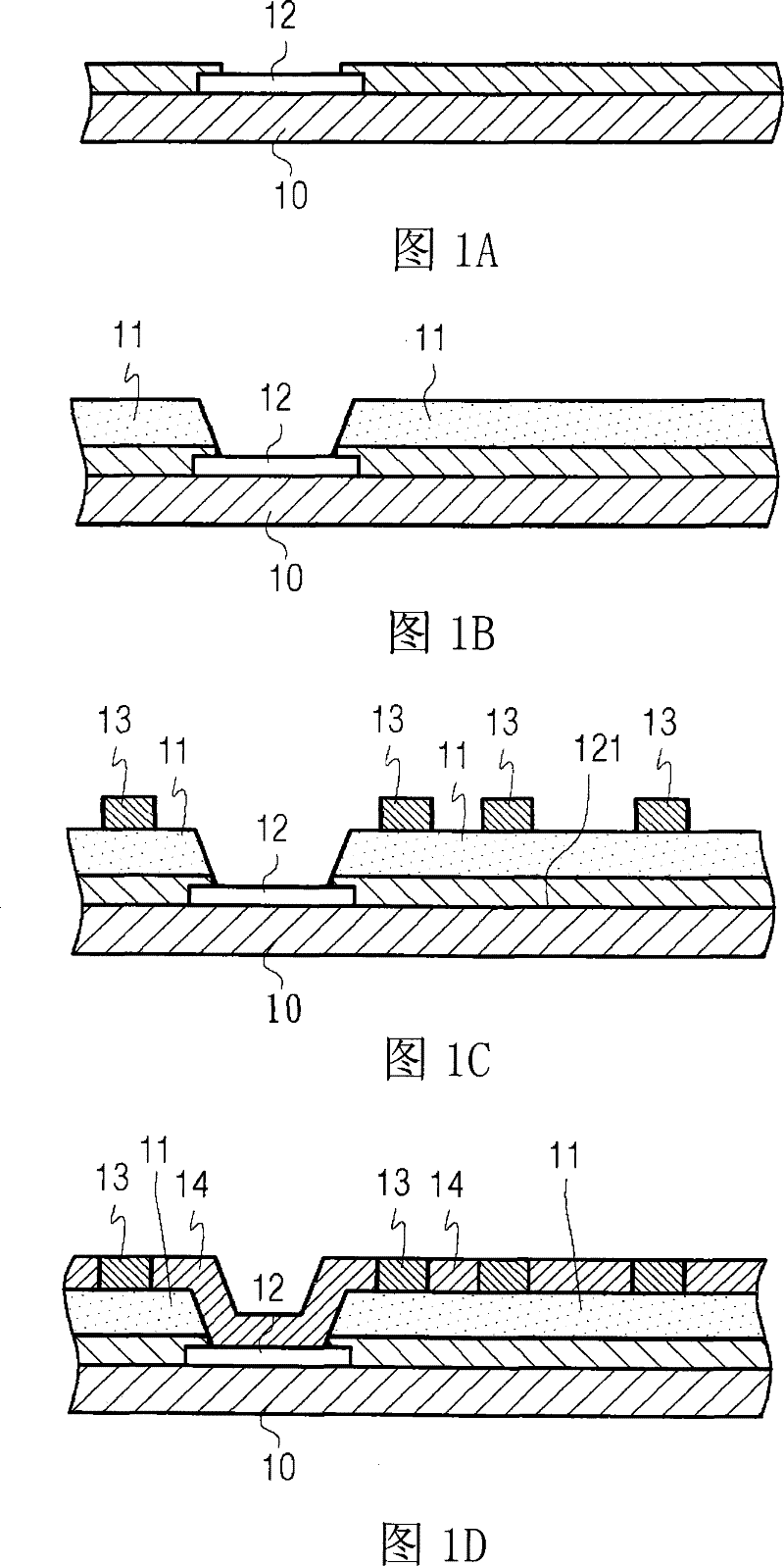

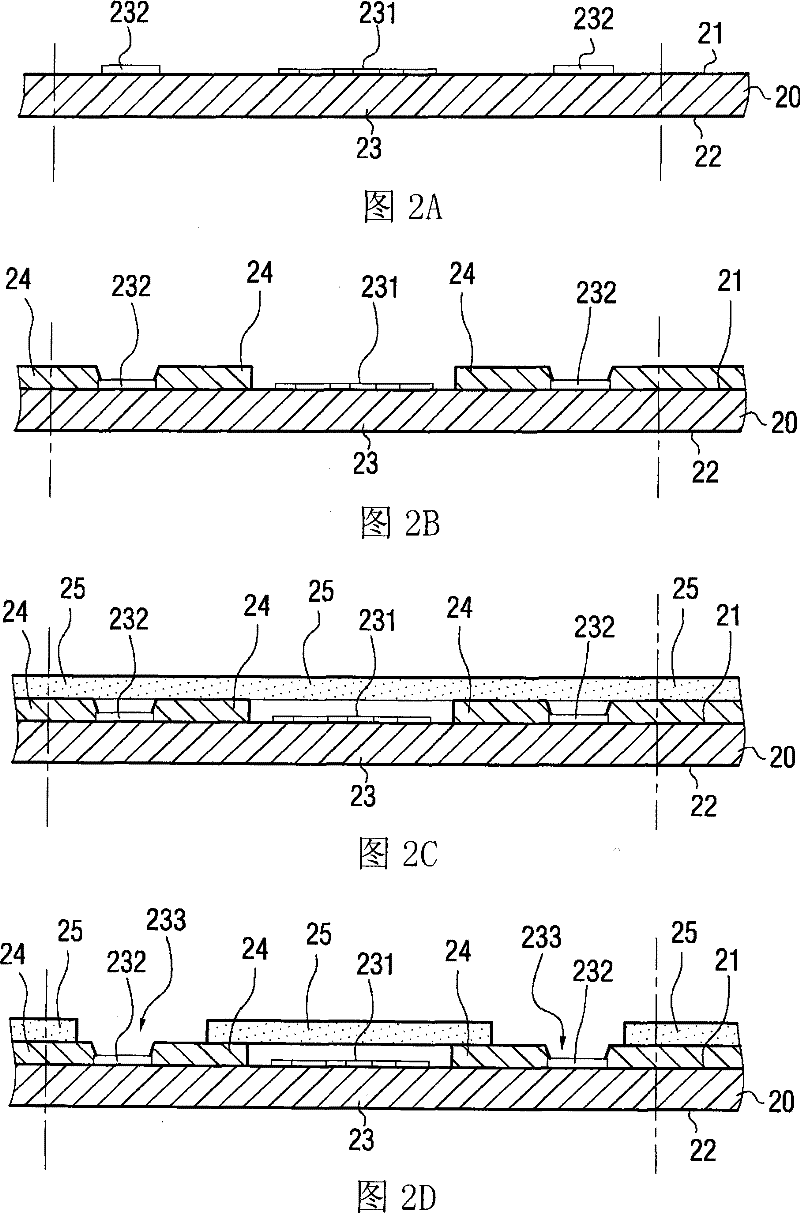

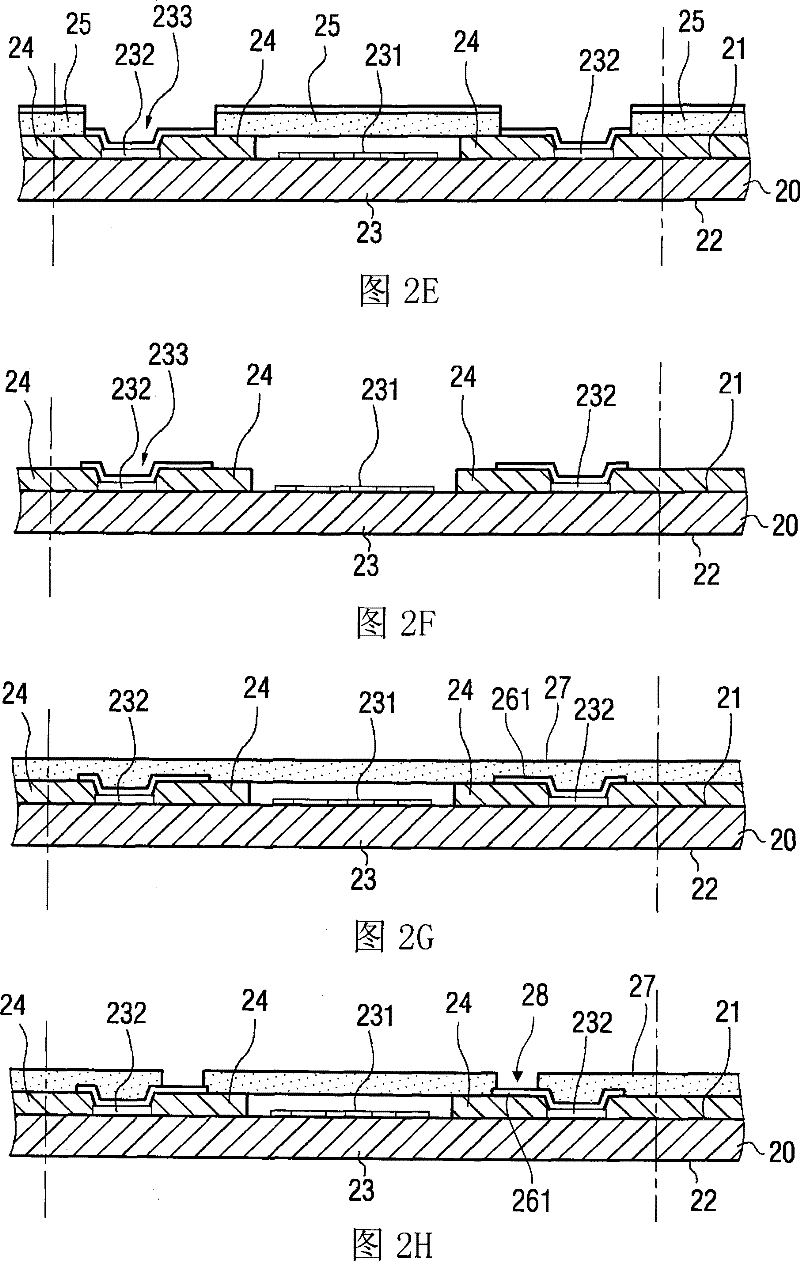

[0031] The preferred embodiments of the present invention are described in detail as follows in conjunction with the accompanying drawings.

[0032] see Figure 2A and Figure 2K A schematic structural flow diagram of an embodiment of the fabrication method of the wafer-level sensing assembly structure of the present invention is shown. It comprises the following steps: first provide a chip 20, especially a sensing chip, the chip 20 is made up of a plurality of sensing chips 23, the chip 20 has a chip surface 21 and the opposite chip back 22, each chip on the chip surface 21 The sensing chip 23 includes a sensing region 231 and a plurality of bonding pads 232 ( Figure 2A shown). Then form a stress release layer 24 on the wafer surface 21 (it is mainly used for force buffering, and is often called a stress buffer layer), and its stress release layer 24 exposes the sensing region 231 and the welding pad 232 of the sensor chip 23 ( Figure 2B shown). Then coat a photoresist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com