Medical waste pyrolysis incinerator

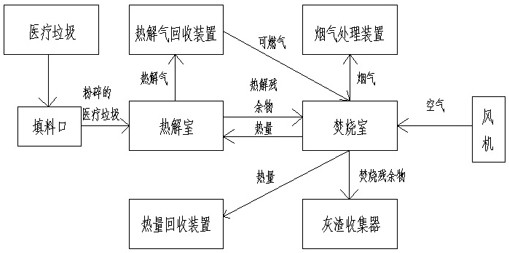

A medical waste and incinerator technology, applied in incinerators, combustion methods, combustion types, etc., can solve the problems of inability to handle large quantities of medical waste, not meeting the requirements of the era of energy conservation and emission reduction, and inability to properly handle special waste, etc. Achieve the effect of reducing the difficulty of setting, saving resources and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

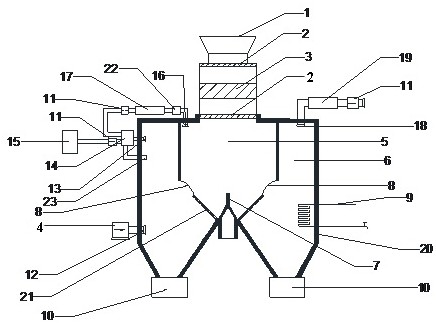

[0022] A pyrolysis incinerator for medical waste, comprising a filling port 1 , a pyrolysis chamber 5 , an incineration chamber 6 , a flue gas purification device 19 , an ash collector 10 , a pyrolysis gas recovery device and a heat recovery device 9 .

[0023] A pulverizer 3 and the pyrolysis chamber 5 are sequentially arranged below the filling port 1, and an openable airtight door 2 is arranged between the pulverizer 3 and the filling port 1, and between the pulverizer 3 and the pyrolysis chamber 5. , the incineration chamber 6 is wrapped around the periphery of the pyrolysis chamber 5, and the heat generated by incineration in the incineration chamber 6 provides working energy for the pyrolysis chamber 5. The bottom of the pyrolysis chamber 5 is provided with a stirring device 7, and on the side wall of the pyrolysis chamber 5 There is a furnace door 8 for pyrolysis residues to be discharged to the incineration chamber 6. The incineration chamber 6 is an inverted concave sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com