Motorcycle brake system

A braking system, motorcycle technology, applied to bicycle brakes, brakes, bicycle accessories, etc., can solve problems such as impact/pulsation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

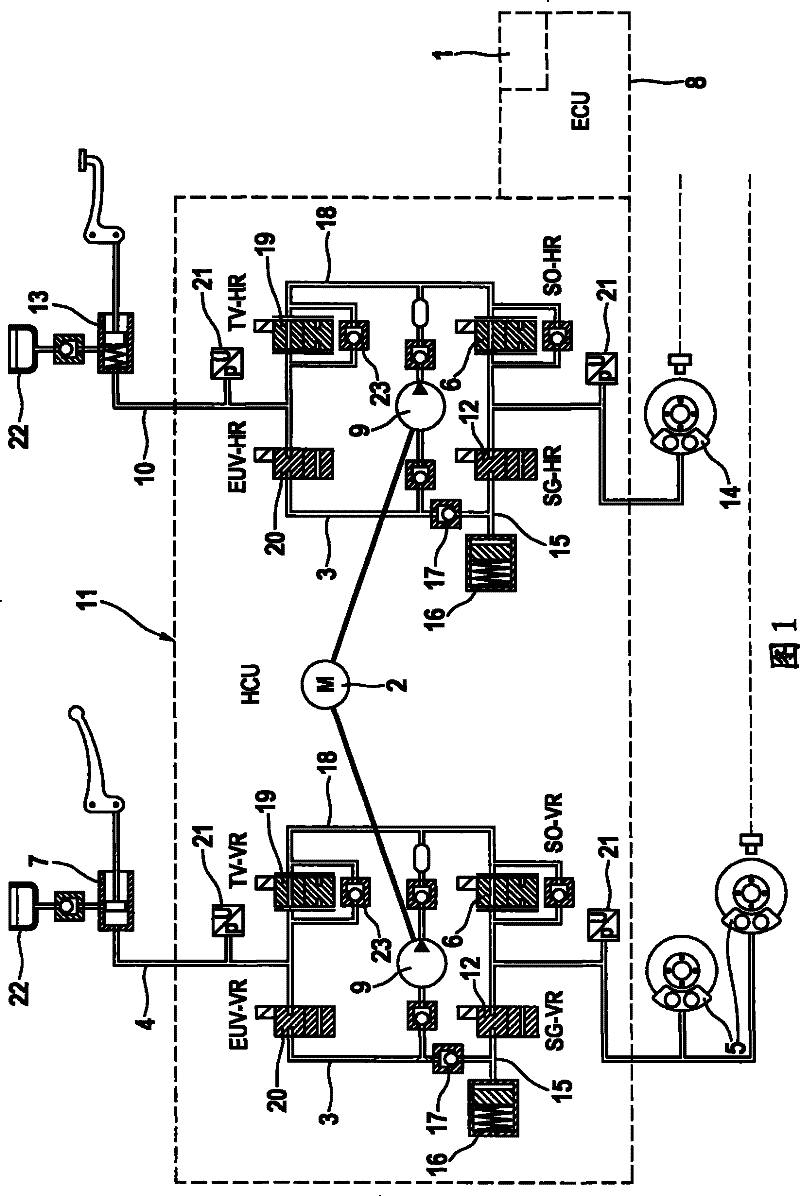

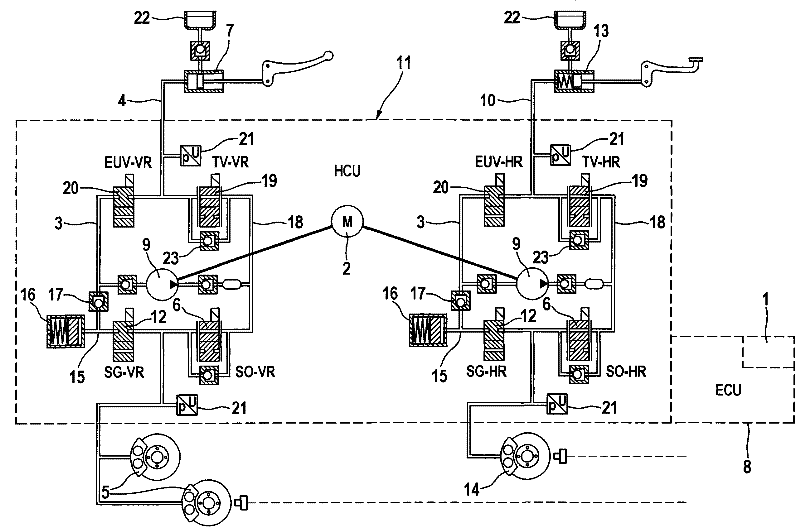

[0007] FIG. 1 shows schematically a hydraulic circuit diagram for a motorcycle brake system with the essential features of the invention. The braking system comprises hydraulically operable front and rear wheel brake circuits 4, 10 each having a master brake cylinder 7 connected to the front wheel brake circuit 4 and operable by hand and a Master brake cylinder 13 on rear wheel brake 14 actuated in proportion to foot force.

[0008] For brake slip control, solenoid-operated inlet and outlet valves 6, 12 are provided in the front and rear brake circuits 4, 10, wherein an inlet valve 6, which is open in the normal position Installed in the brake lines of the front wheel brake circuit and the rear wheel brake circuit 4, 10 respectively, these brake circuits are connected to the corresponding master brake cylinders 7, 13 through the isolation valve 19 opened in the normal position to front wheel brake 5 or rear wheel brake 14. The discharge valve 12 closed at the normal position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com