Precise forming mold of water lubrication rubber alloy bearing

A rubber alloy, precision molding technology, applied in household appliances, other household appliances, household components, etc., can solve the problems of destroying the bushing structure, the mold has no positioning function, affecting the service life of the bearing and the efficiency of the transmission, etc., to achieve installation and disassembly Easy maintenance, enhanced product compactness, and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

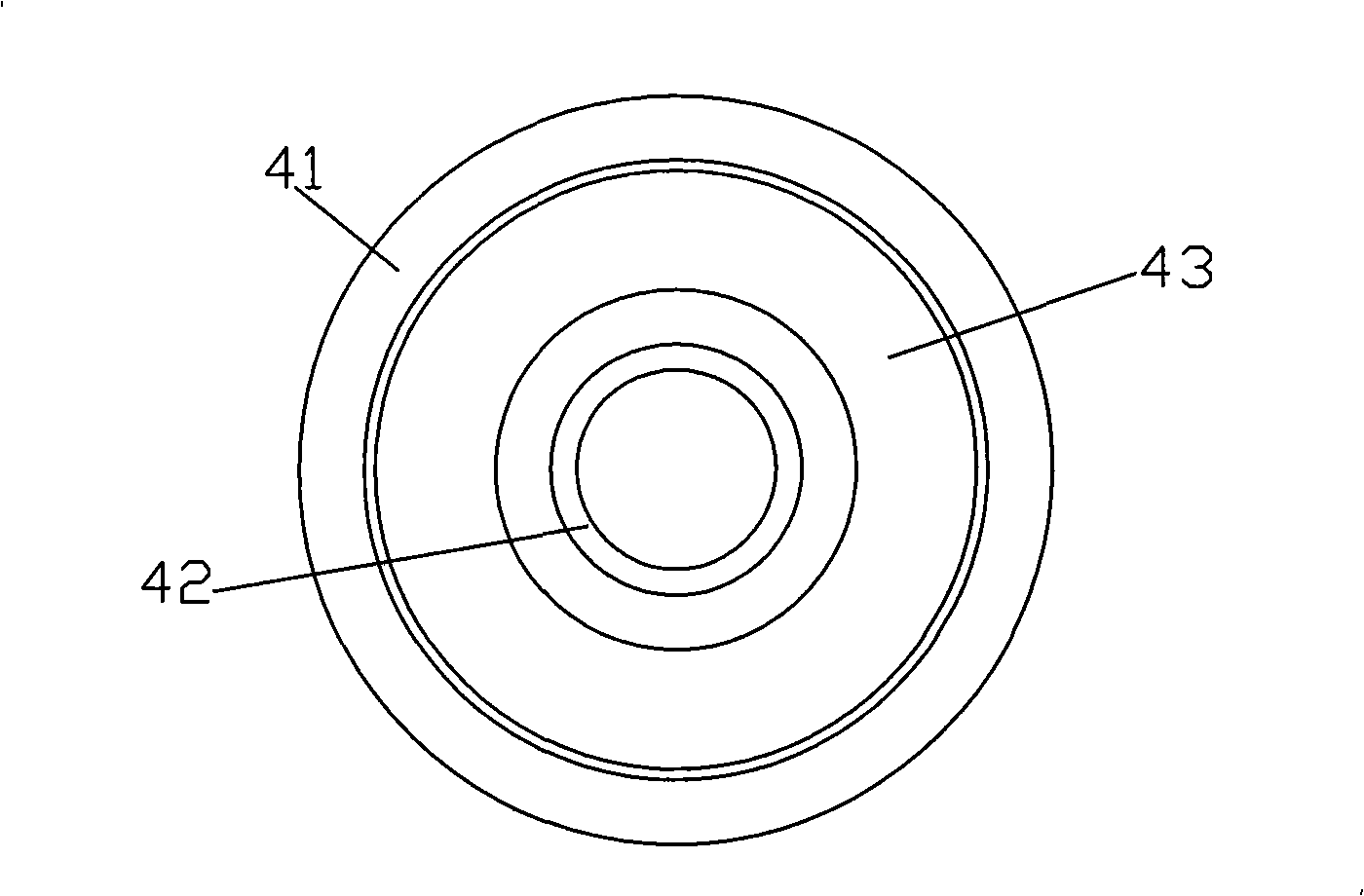

[0031] Figure 6 It is a structural schematic diagram of the second embodiment of the present invention, as shown in the figure: the difference between this embodiment and the first embodiment is: the upper end cover 4 is provided with a sinker 45 at the position corresponding to the end face of the mold body 1, and the lower end cover 3 and the mold body 1 and the axial gap between the mold core 2 is provided with an annular groove II33, and the annular groove II33 communicates with the outside world through the glue outlet hole II11 provided on the lower end cover 3, while the upper end cover is not provided with a glue outlet hole; The mold with this structure is used to produce flanged water-lubricated rubber alloy bearings.

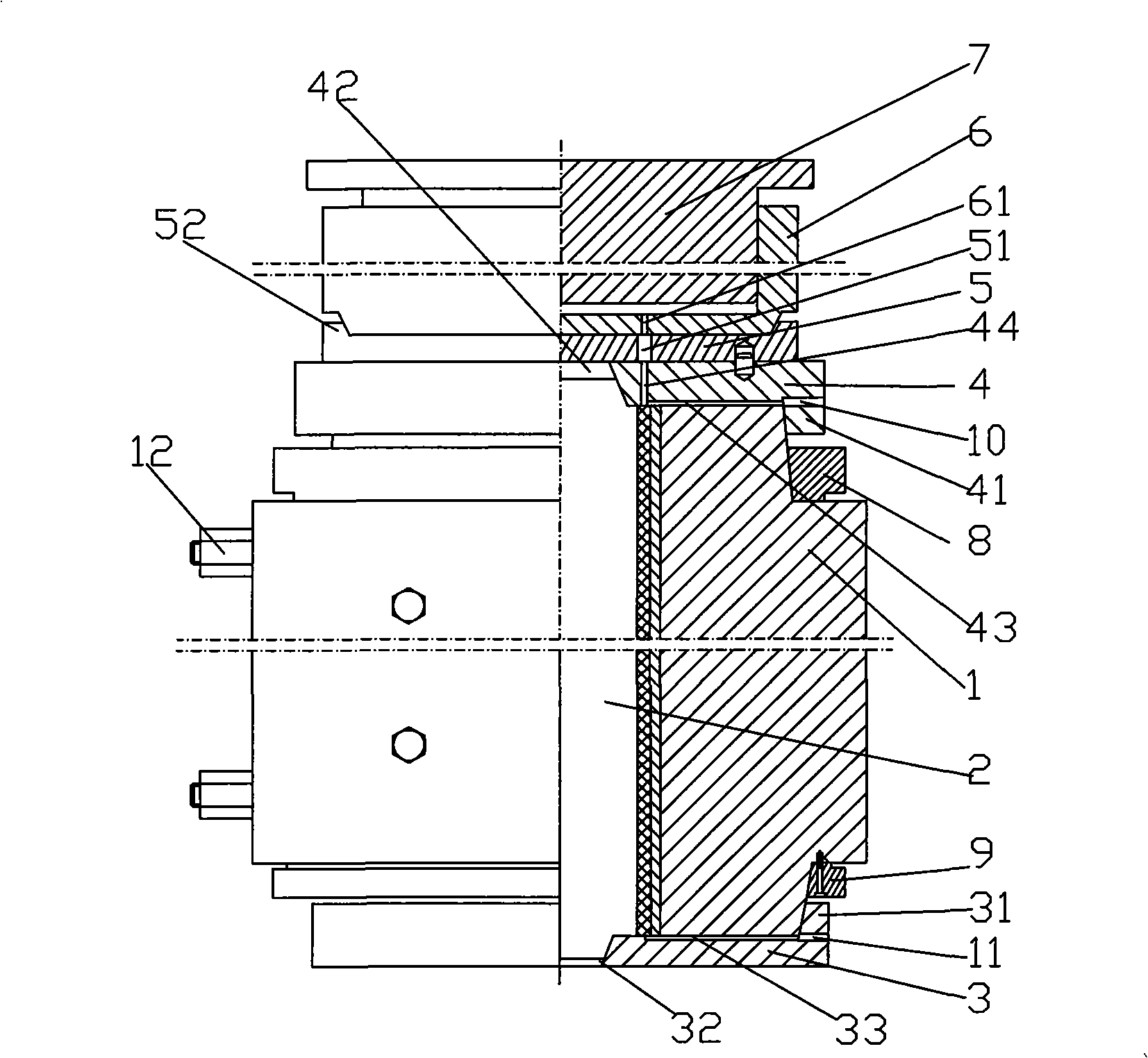

[0032] When the present invention is in use, the cylindrical or flanged copper tube bearing outer ring is placed in the middle of the mold body 1 with a Huff structure, and the bearing outer ring and the mold body 1 are in clearance fit; then the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com