Ink ribbon cartridge capable of automatically stopping supplying ink

An automatic stop and ink cartridge technology, applied in printing and other fields, can solve the problems of increasing the production cost of ink cartridges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

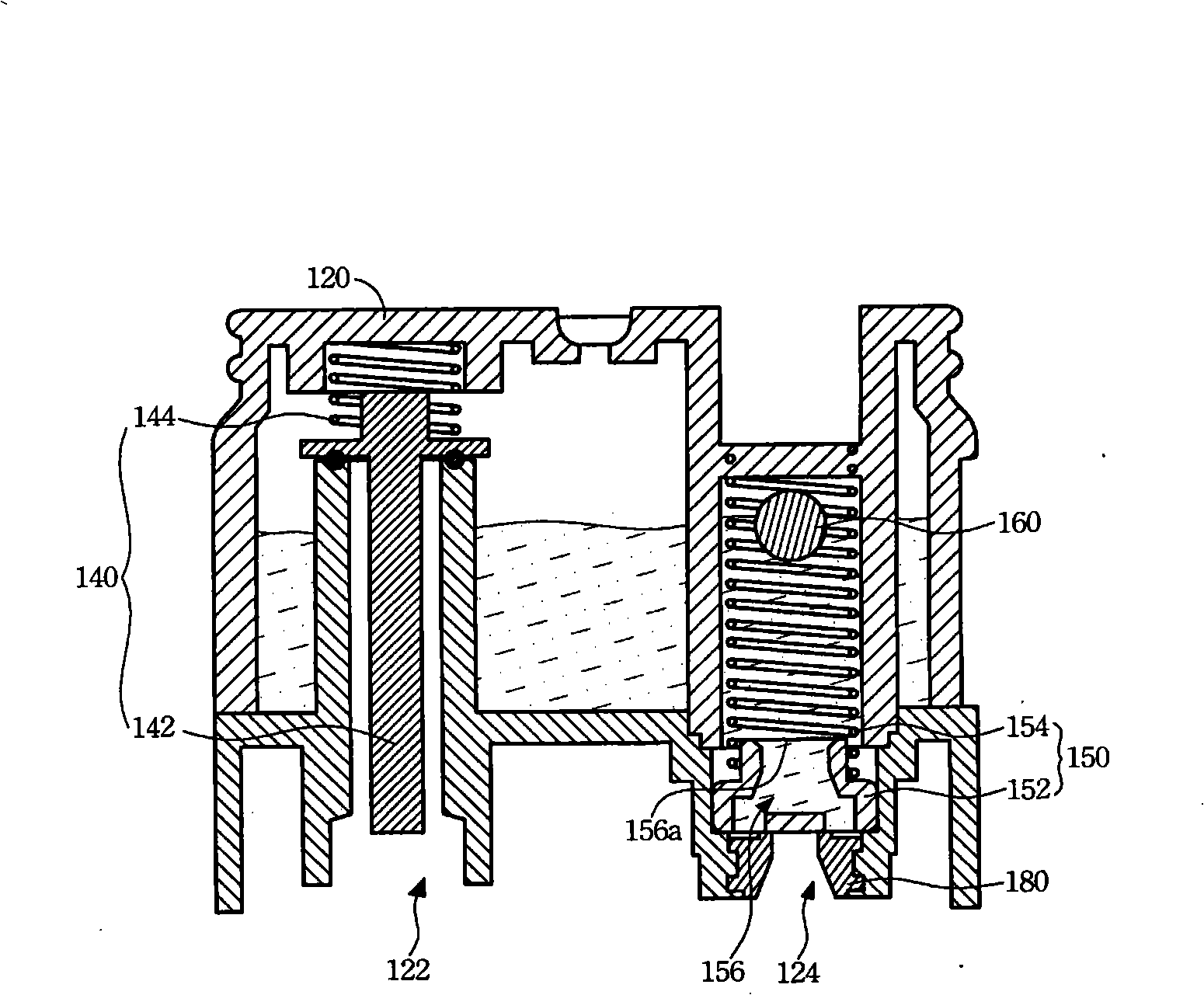

[0021] Please refer to figure 1 It is a schematic cross-sectional view of a preferred embodiment of the ink cartridge 100 that automatically stops ink supply in the present invention. As shown in the figure, the ink cartridge 100 includes a reservoir 120 , an air valve 140 and a float 160 . Wherein, the storage 120 is used for containing ink. The reservoir has an air inlet channel 122 and an ink flow path 124 . The air valve 140 is disposed on the air inlet passage 122 for preventing ink from flowing out of the ink cartridge 100 through the air inlet passage 122 . The air valve 140 has an air valve body 142 and an air valve spring 144 . Wherein, the air valve body 142 is disposed in the intake passage 122 . The gas valve spring 144 is located between the gas valve body 142 and the reservoir 120 . When the air valve 140 is opened, the air valve spring 144 is compressed to generate an elastic restoring force to drive the air valve body 142 to close the intake passage 122 . ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap