Supercharging gasoline engine air administrative system

An air management system and gasoline engine technology, applied in mechanical equipment, combustion engines, machines/engines, etc., can solve the problems of insufficient turbocharged low-speed torque of gasoline engines, and achieve good control of intake air temperature, high boost ratio, and improved low-speed torque Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

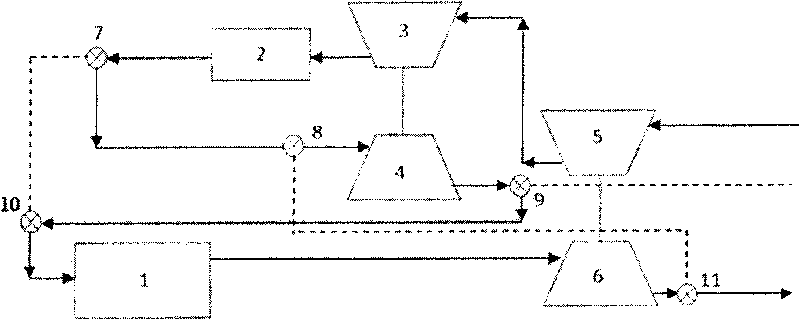

[0018] figure 1 It is a schematic flow chart of the first system of the present invention under medium and high-speed working conditions. The main compressor 5, the double-effect turbine compressor 3, the intercooler 2, the double-effect turbine 4, the cylinder 1 and the main turbine 6 are sequentially connected in series. After the gas is compressed and boosted by the main compressor 5, it enters the double-effect turbo compressor 3 for secondary boost; then enters the intercooler 2, and is cooled by heat exchange with the cooling medium; then the gas passes through the first valve 7 And the second valve 8 enters the double-effect turbine 4, through expansion, the intake air temperature is reduced, and it enters the cylinder 1 through the third valve 9 and the fourth valve 10; after the gas is burned in the cylinder 1, it passes through the main turbine 6 and the second Five valves 11 discharge. When the intake air temperature meets the requirements, the double-effect turbin...

Embodiment 2

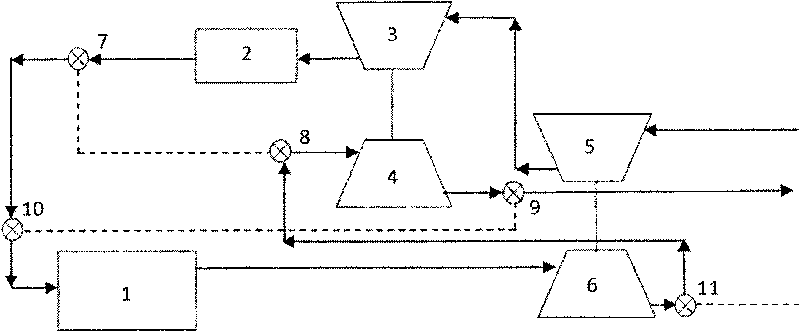

[0020] figure 2 It is a schematic flow chart of the first system of the present invention under low-speed working conditions. The main compressor 5, the double-effect turbine compressor 3, the intercooler 2, the cylinder 1, the main turbine 6 and the double-effect turbine 4 are connected in series in sequence. After the gas is compressed and boosted by the main compressor 5, it enters the double-effect turbo compressor 3 for secondary boost; then enters the intercooler 2, and is cooled by heat exchange with the cooling medium; then the gas passes through the first valve 7 And the fourth valve 10 enters the cylinder 1. After the gas burns in the cylinder 1 and does work, it passes through the main turbine 6. Due to the small gas flow under low-speed conditions, the expansion ratio of the gas at the main turbine 6 is close to 1; then the gas passes through the fifth valve. 11 and the second valve 8, enter the double-effect turbine 4, and the exhaust gas is expanded at the doubl...

Embodiment 3

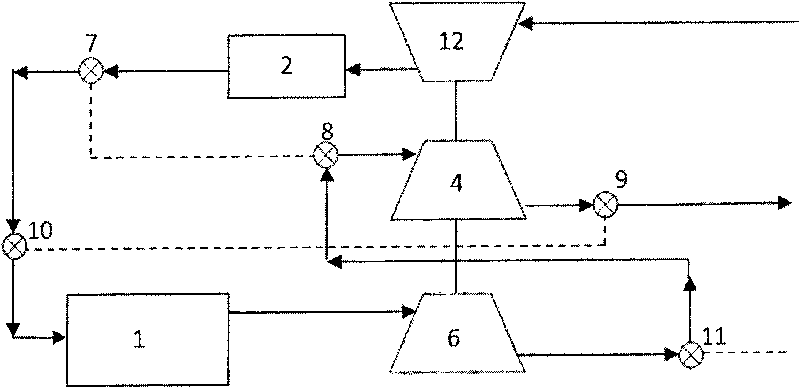

[0023] image 3 It is a schematic flow chart of the second system of the present invention at medium and high speed working conditions, the main compressor 5 and the double-effect turbine compressor 3 are combined into a compressor 12, and the compressor 12 is coaxial with the double-effect turbine 4 and the main turbine 6 Arrangement; compressor 12, intercooler 2, double-effect turbine 4, cylinder 1 and main turbine 6 are connected in series in sequence. After the gas is compressed and boosted by the compressor 12, it enters the intercooler 2 and is cooled by heat exchange with the cooling medium; then the gas enters the double-effect turbine 4 through the first valve 7 and the second valve 8, and expands to make The temperature of the intake air decreases, and it enters the cylinder 1 through the third valve 9 and the fourth valve 10; the gas is discharged through the main turbine 6 and the fifth valve 11 after combustion in the cylinder 1. When the intake air temperature m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com