Energy recovery device and method for lng engine based on temperature difference power generation technology

An energy recovery device, a technology of thermoelectric power generation, which is applied to generators/motors, engine components, combustion engines, etc., can solve the problems of ineffective use of energy, energy waste, low thermal efficiency, etc., to improve fuel economy and energy. Recovery efficiency and thermal management effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

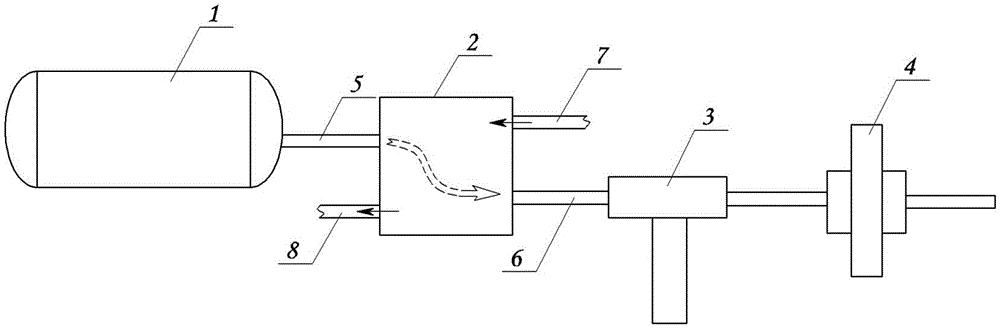

[0019] Embodiment 1: A kind of LNG engine energy recovery device based on thermoelectric power generation technology, see figure 1 , the device includes LNG tanks, thermoelectric generators, filters, regulators and mixers and other components. Wherein, the exhaust port of the LNG gas tank 1 is connected with the inlet of the cold end of the thermoelectric generator 2 through the LNG inlet pipe 5, and the outlet of the gasifier of the LNG engine is connected with the inlet of the hot end of the thermoelectric generator 2 through the coolant inlet pipe 7. 2 The outlet of the hot end is connected to the inlet of the LNG engine carburetor, and the outlet of the cold end of the thermoelectric generator 2 is connected with the filter 3, the voltage stabilizer 4, and the mixer in turn through the LNG outlet pipe as fuel for the LNG engine.

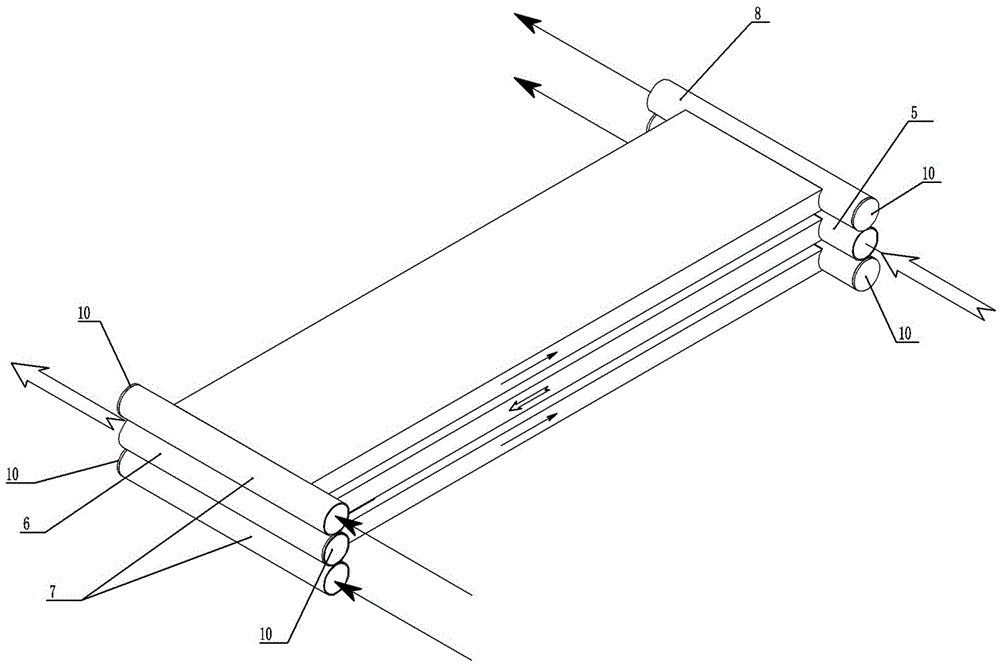

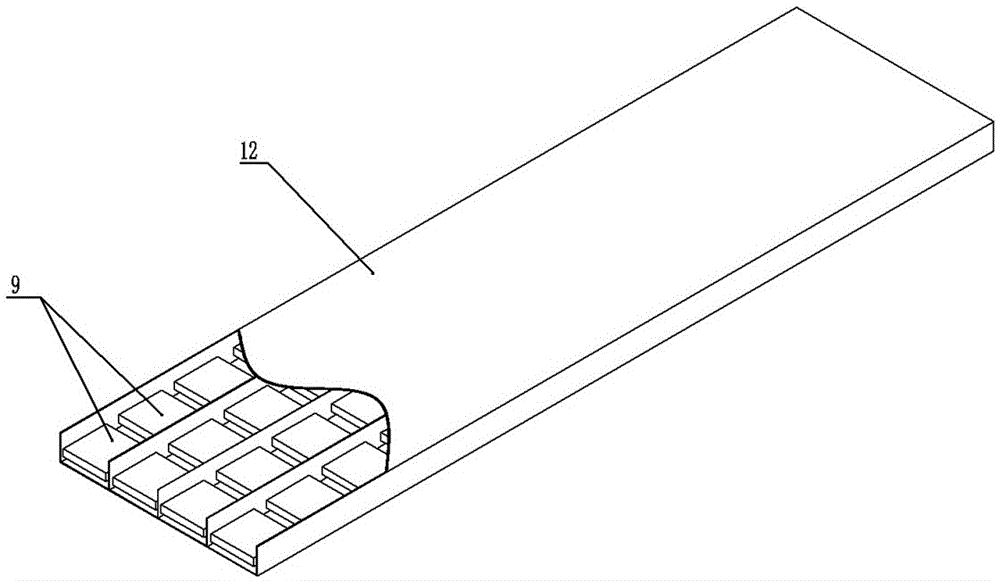

[0020] Such as Figure 2-Figure 4 As shown, the thermoelectric generator 2 includes three layers of porous flat tubes 12 superimposed on each ...

Embodiment 2

[0021] Embodiment 2: The accompanying drawings are not drawn, and the content is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that the thermoelectric generator includes five layers of multi-layer porous flat tubes stacked on top of each other, and the upper layer of multi-hole flat tube coolant passages. One end is the coolant inlet pipe, and the other end is the coolant outlet pipe; the adjacent lower porous flat pipe is the LNG channel, one end of which is the LNG inlet pipe, and the other end is the LNG outlet pipe; the coolant channels and LNG channels are arranged alternately.

Embodiment 3

[0022] Embodiment 3: A method for recovering energy from an LNG engine based on thermoelectric power generation technology, using the gasification cooling capacity of the LNG gas tank as the cold end, using the engine cooling water as the hot end, and the cold end and the hot end are respectively located on both sides of the thermoelectric power generation sheet, The thermoelectric power generation technology is used to recover energy, and the gasified LNG is used as LNG engine fuel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com