Machine group scheduling method based on process capacity characteristic model

A processing capability and feature model technology, applied in gene model, comprehensive factory control, comprehensive factory control, etc., can solve problems such as performance degradation of optimal scheduling scheme of machine groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

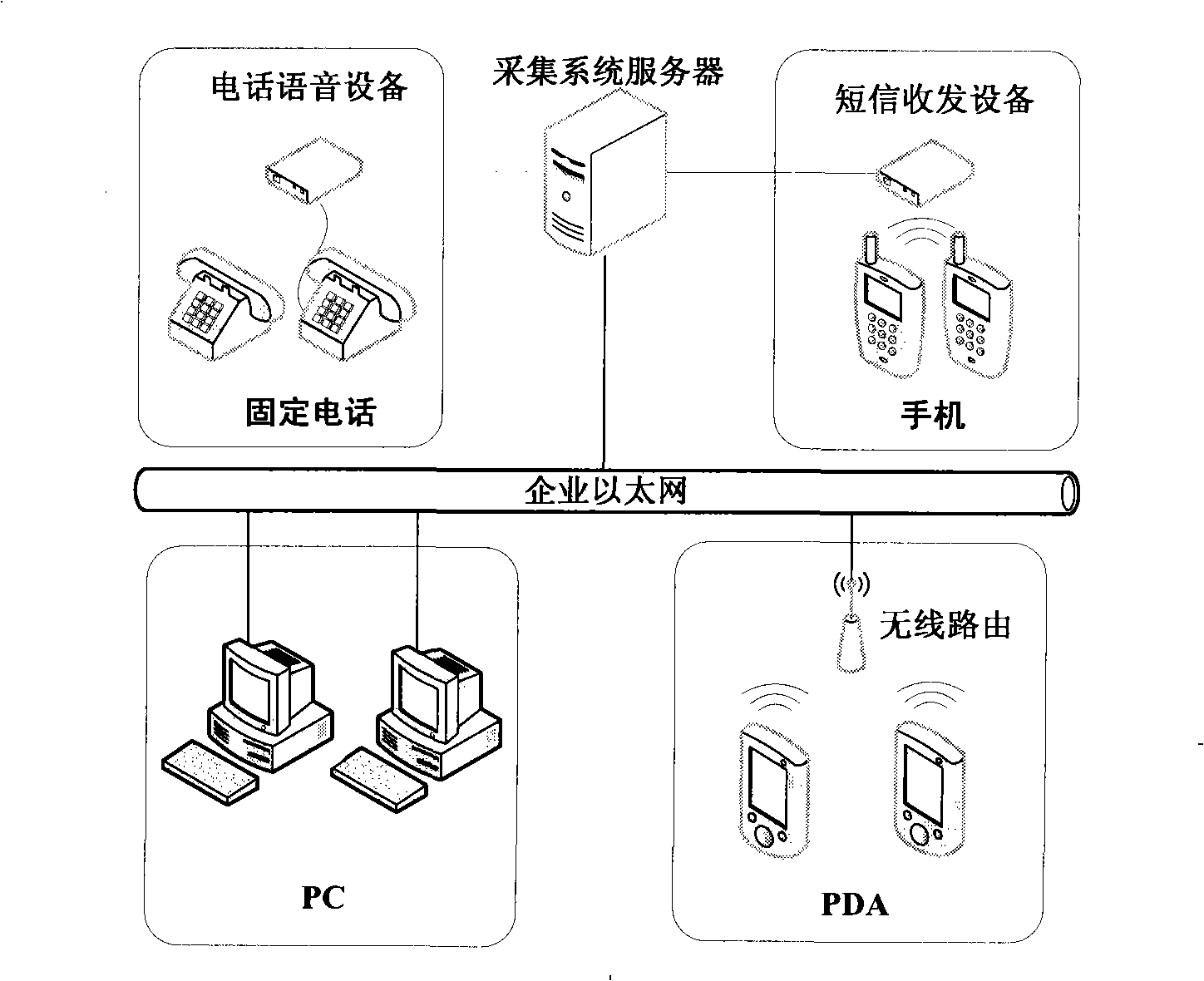

[0077] The machine group scheduling method based on the processing capability characteristic model in the present invention depends on the scheduling related information obtained by the scheduling information collection hardware system (hereinafter referred to as the collection system). The acquisition system consists of networked PCs in the enterprise LAN (generally adopt barcode or keyboard input method for information acquisition), PDA in wireless local area network (generally adopt barcode or keyboard input method for information acquisition), mobile phones registered in the acquisition system (generally It is composed of collection terminals such as information collection using SMS), fixed telephones (generally using voice calls for information collection), as well as collection servers and dedicated communication devices (telephone voice equipment, SMS collection equipment, etc.). The hardware configuration of the acquisition system is as follows: figure 1 shown.

[007...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com