Driving mechanism for neutron producer detection

A technology of neutron source and power transmission mechanism, which is applied in the field of nuclear detection, can solve the problem of inaccurate positioning of the neutron source driving device and achieve the effect of simple circuit and accurate position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

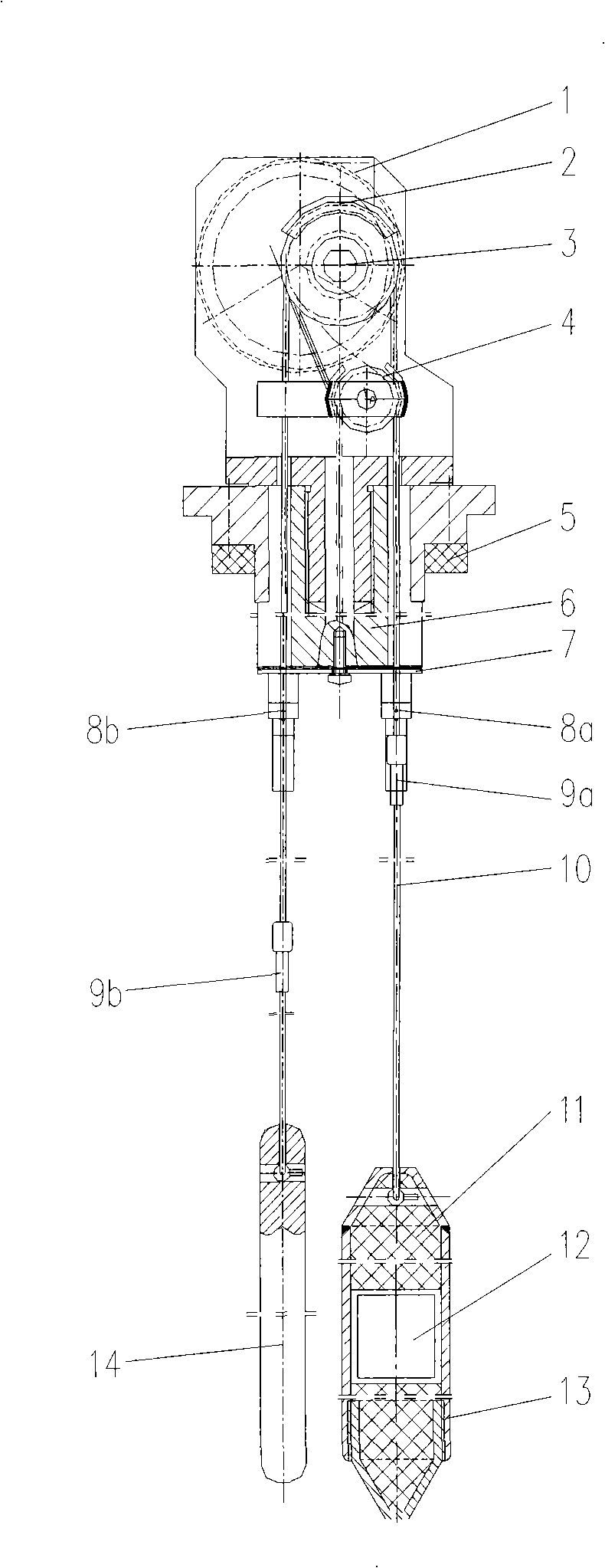

[0015] The technical solution of the present invention will be further elaborated below in conjunction with the accompanying drawings.

[0016] Such as figure 1 As shown, a test neutron source drive mechanism is installed in the upper shielding layer of the reactor through a sealing gasket 5. When performing test operations, the test neutron source is hoisted downward into the detection device of the pile pit through the drive mechanism. To check whether the detectors and instruments are working normally. This operation is carried out remotely through the computer in the control room. Its specific structure is that the inspection neutron source 12 is installed in the shuttle-shaped bucket 13, the shuttle-shaped bucket 13 is tied on the suspension rope 10, and the upper and lower sides of the inspection neutron source in the bucket 13 are also equipped with neutron shielding moderators. 11. Its function is to prevent interference to the detector and damage to the staff in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com