Residual current circuit breaker

A leakage circuit breaker, main circuit technology, applied in the direction of circuits, electrical components, switches operated by ground fault current, etc., can solve the problems of difficult to bend wires, troublesome, soft and damaged insulation tubes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

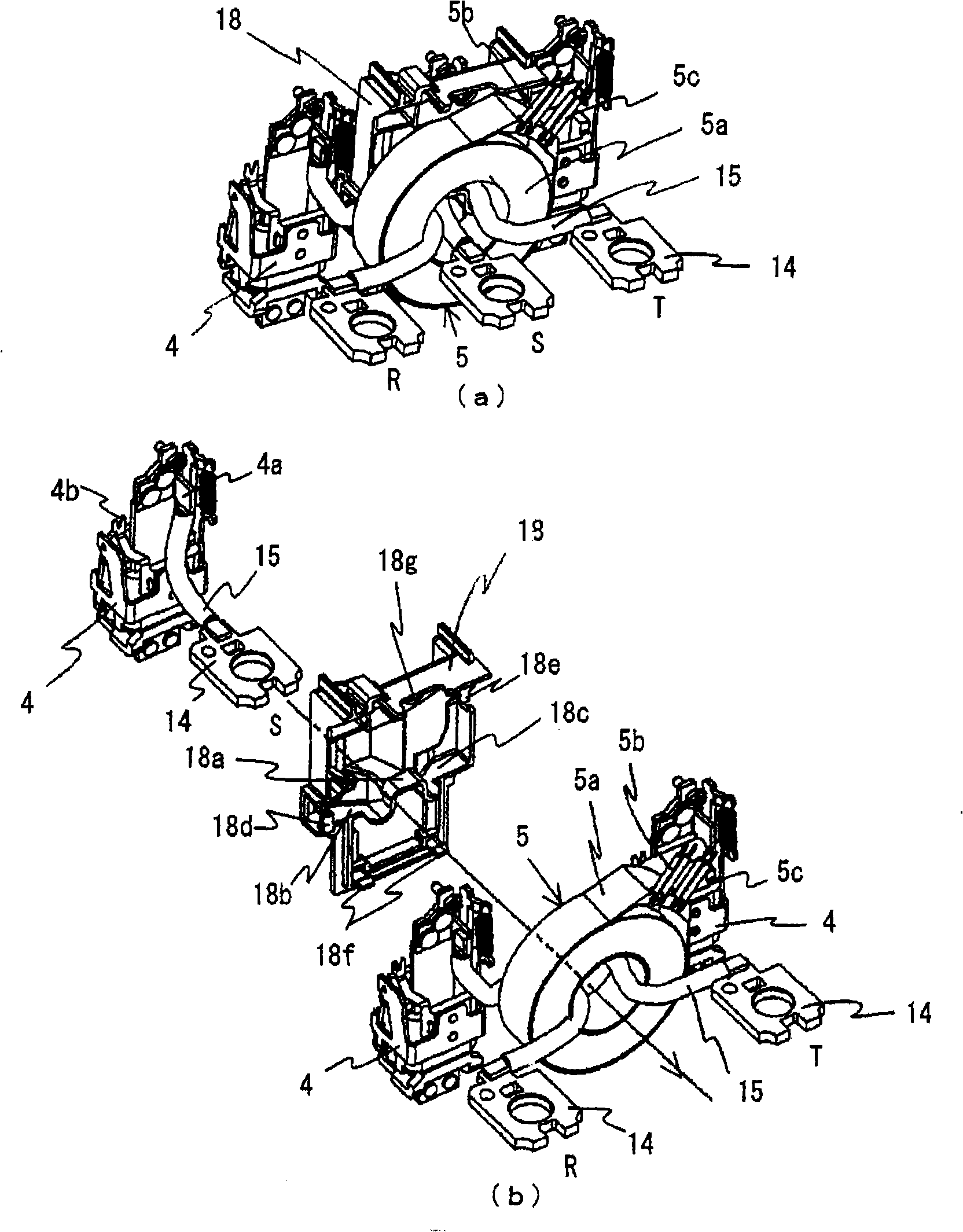

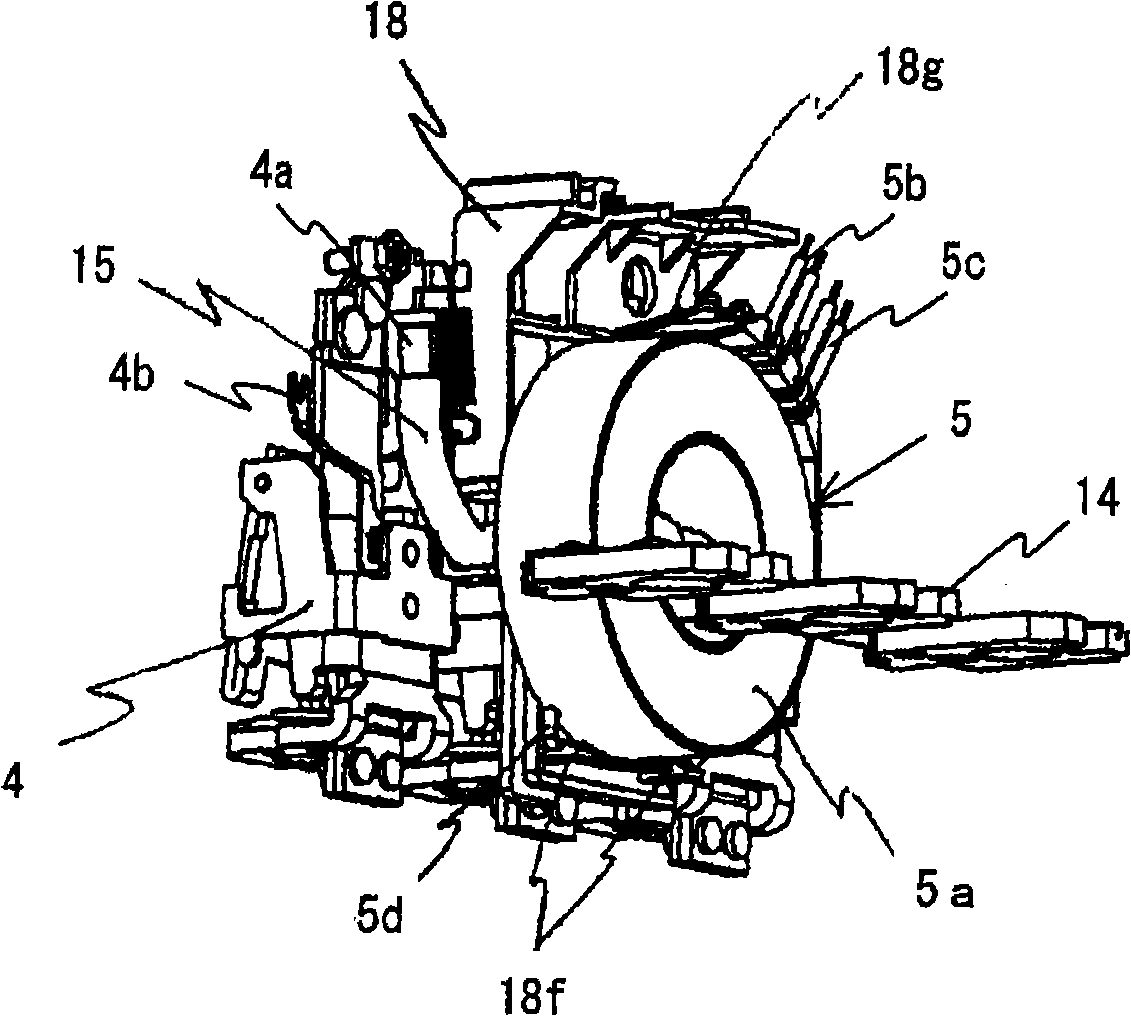

Embodiment 1

[0065] First, according to Figure 1 to Figure 6 , to explain the working procedure of putting the components and the assembled body of the components into the main body box of the circuit breaker, wherein the above components are combined with the unit of the zero-phase current transformer mounted on the 3-pole earth leakage circuit breaker. Peripheral components such as current trip device and load side terminal. That is, in this embodiment, the unit assembly frame 18 produced by the molded resin molding is prepared as a new part. Then, on the unit assembly frame 18, the structure that the overcurrent release device 4 of each pole is combined with the load side terminal 14 and welded to the two ends of the twisted wire 15 penetrates the zero-phase converter, and as Figure 1 ~ Figure 3 As shown, the zero-phase converter 5 is assembled from components centered on the zero-phase converter. In addition, an insulating tube or an insulating tape (for example, Teflon (registered...

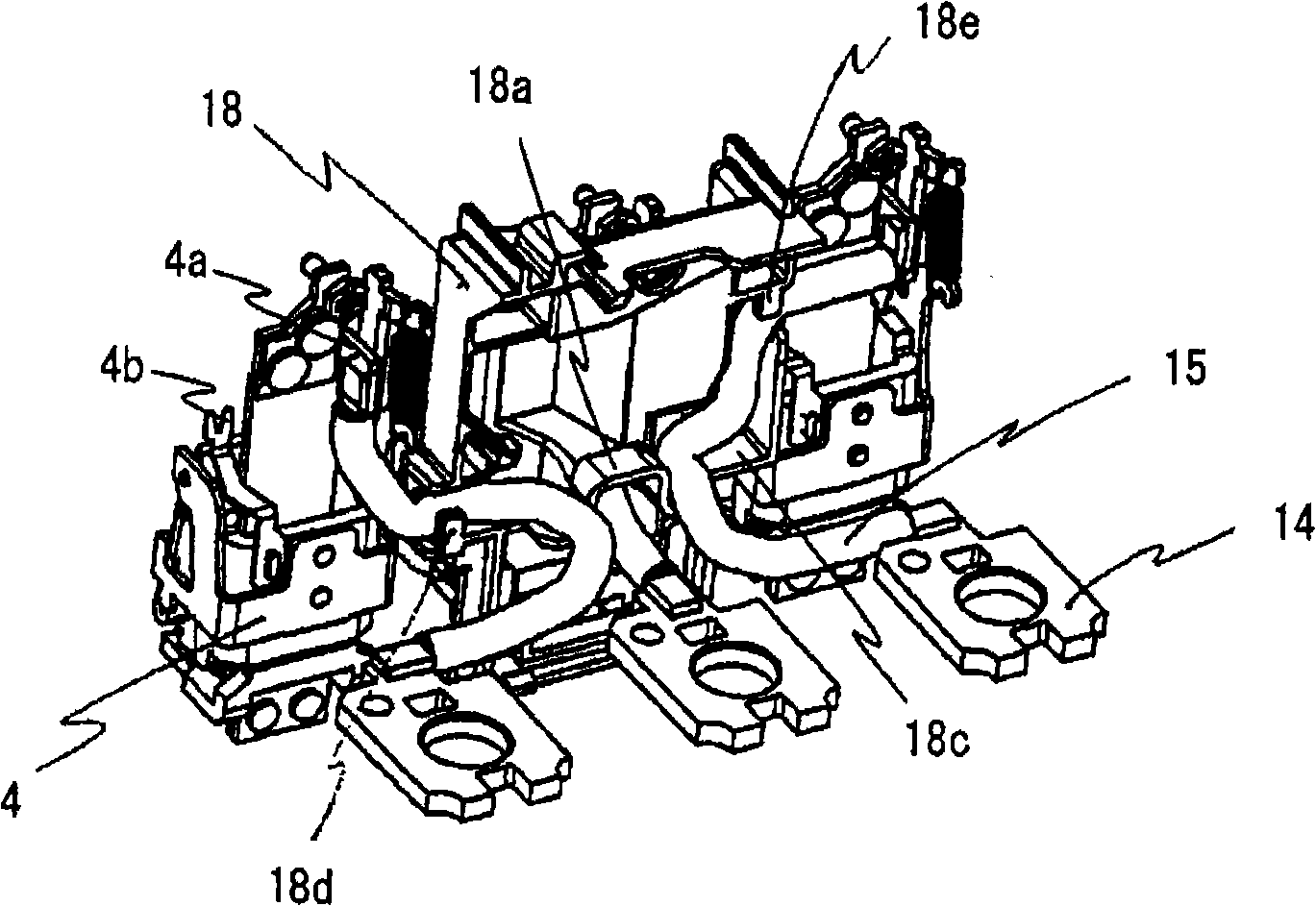

Embodiment 2

[0077] Next, at Figure 7 , Figure 8 The middle shows components of a zero-phase converter mounted on a 4-pole earth leakage circuit breaker applied to a three-phase, four-wire circuit. That is, in this embodiment, the unit assembly frame 18 described in the above-mentioned embodiment 1 is used as a common part, and the zero-phase converter 5, R, S, T phases, and three-phase 4-wire circuit are installed on it. Correspondingly, the stranded wire 15 added as the N-phase (neutral line) through the primary conductor is further combined with the overcurrent release device 4 of each pole and the load-side terminal 14 to form a zero-phase converter 5 as the center. Assembly of components. Here, the twisted wire 15 of the N-phase passes through the zero-phase converter 5 as shown in the figure and is routed and arranged, and the middle part of its wiring path is pressed into the recess 18h of the unit assembly frame 18 (refer to Figure 8 ) and keep it on the frame. In addition, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com