Automobile hub bearing slurry salty liquor and general durability test method and test machine

A durability test, wheel bearing technology, applied in the direction of mechanical bearing testing, etc., can solve the problems of incompatibility with rapid development, restricting the improvement and perfection of automobile wheel bearing structure, and achieve scientific and reasonable design structure, true, accurate and reliable detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

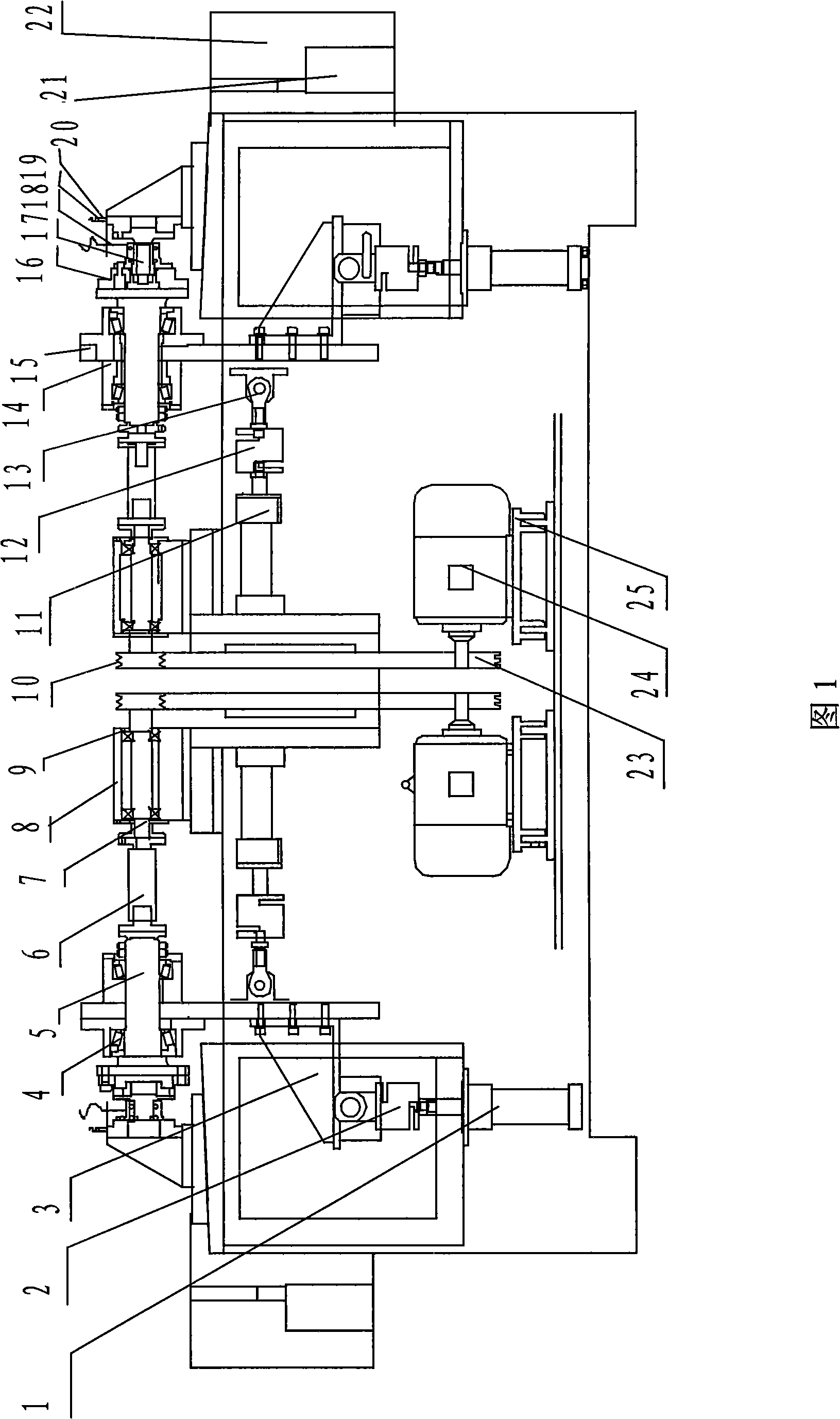

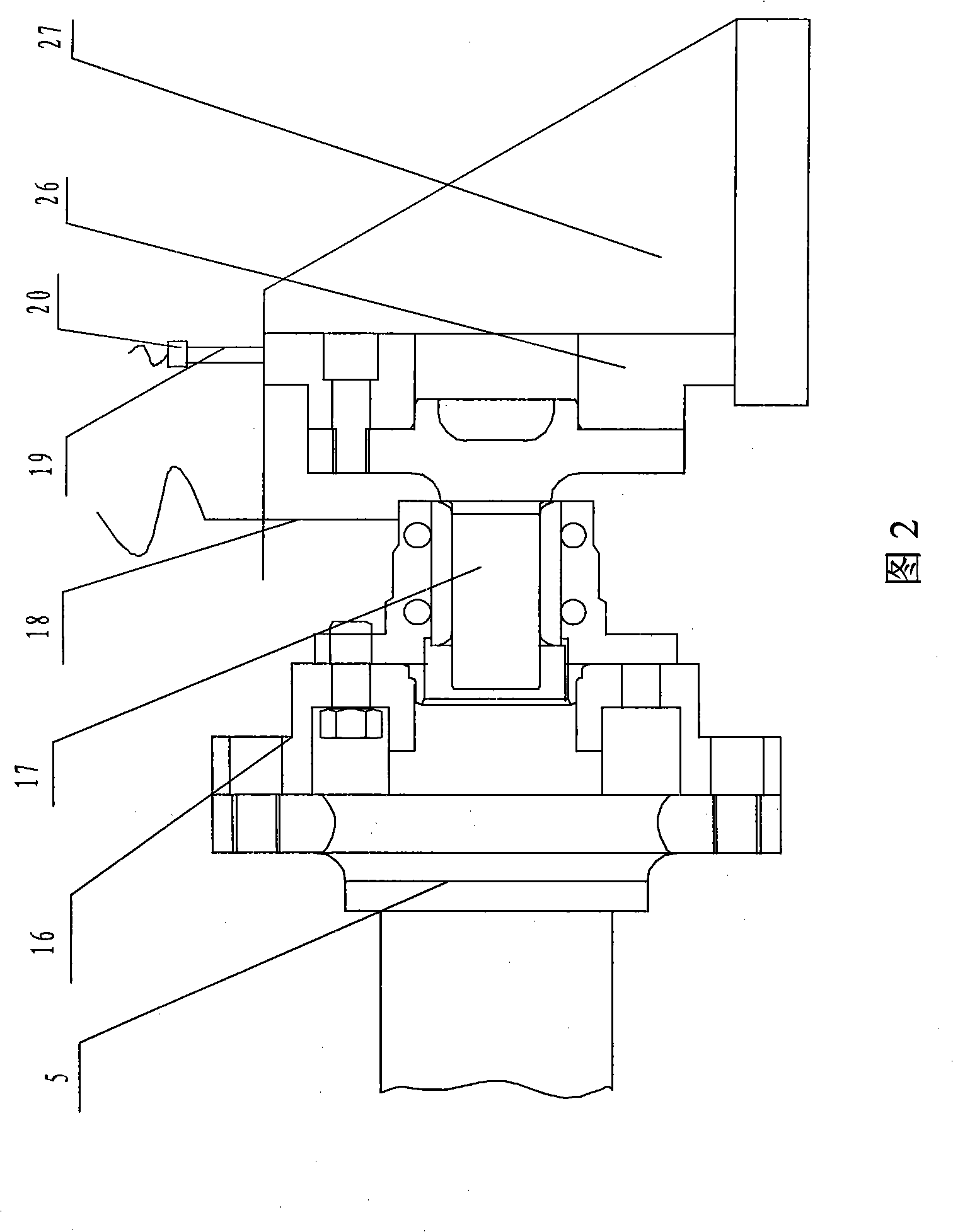

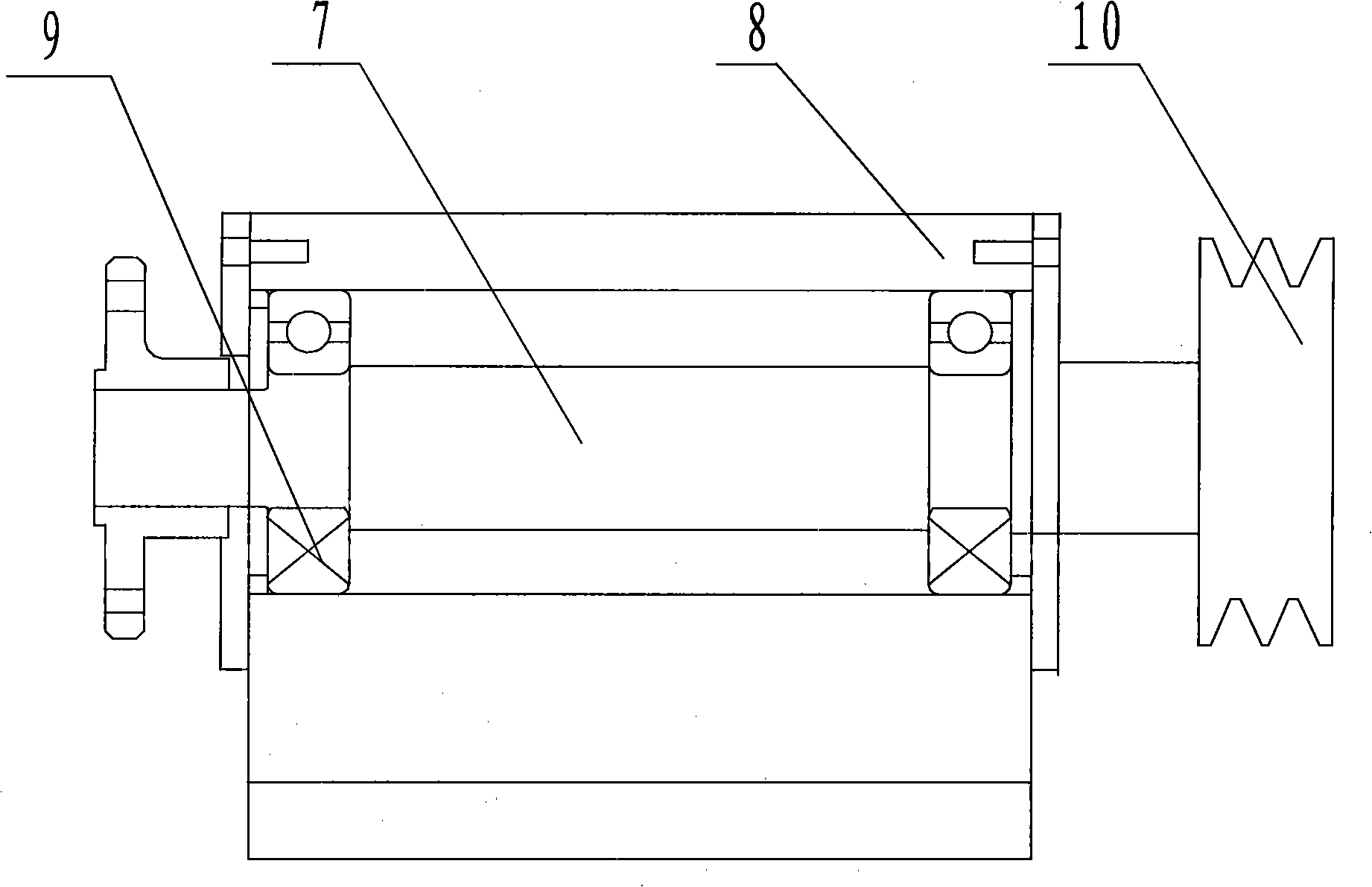

[0015] Embodiments of the utility model are described in conjunction with the accompanying drawings:

[0016] The test hub bearing test method that the present invention proposes is:

[0017] The test hub bearing 17 is cantilever-supported on the test bench, that is, the inner ring of the test hub bearing 17 is fixed relative to the machine base through the tooling bracket 27 and the tooling panel 26, and the test hub bearing outer casing is connected to the rotating structure through the tooling transition connection flange 16 On the end face of the loading shaft of the test hub bearing, the cantilever structure of the test hub bearing is formed; through the loading shaft, the outer shell of the test hub bearing rotates at a high speed consistent with the speed of the actual working condition, so that the force of the test hub bearing unit is the same as that of the actual vehicle running The working conditions are the same; the rotation of the test hub bearing driven by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com