Electrical steel automatic sample-making system

A technology for automatic sample preparation and electrical steel, which is applied in sampling devices, preparation of samples for testing, etc. It can solve the problems of manual numbering, slow sample preparation, low efficiency, etc., and achieve high production precision, fast sample preparation, Reasonable effect of craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

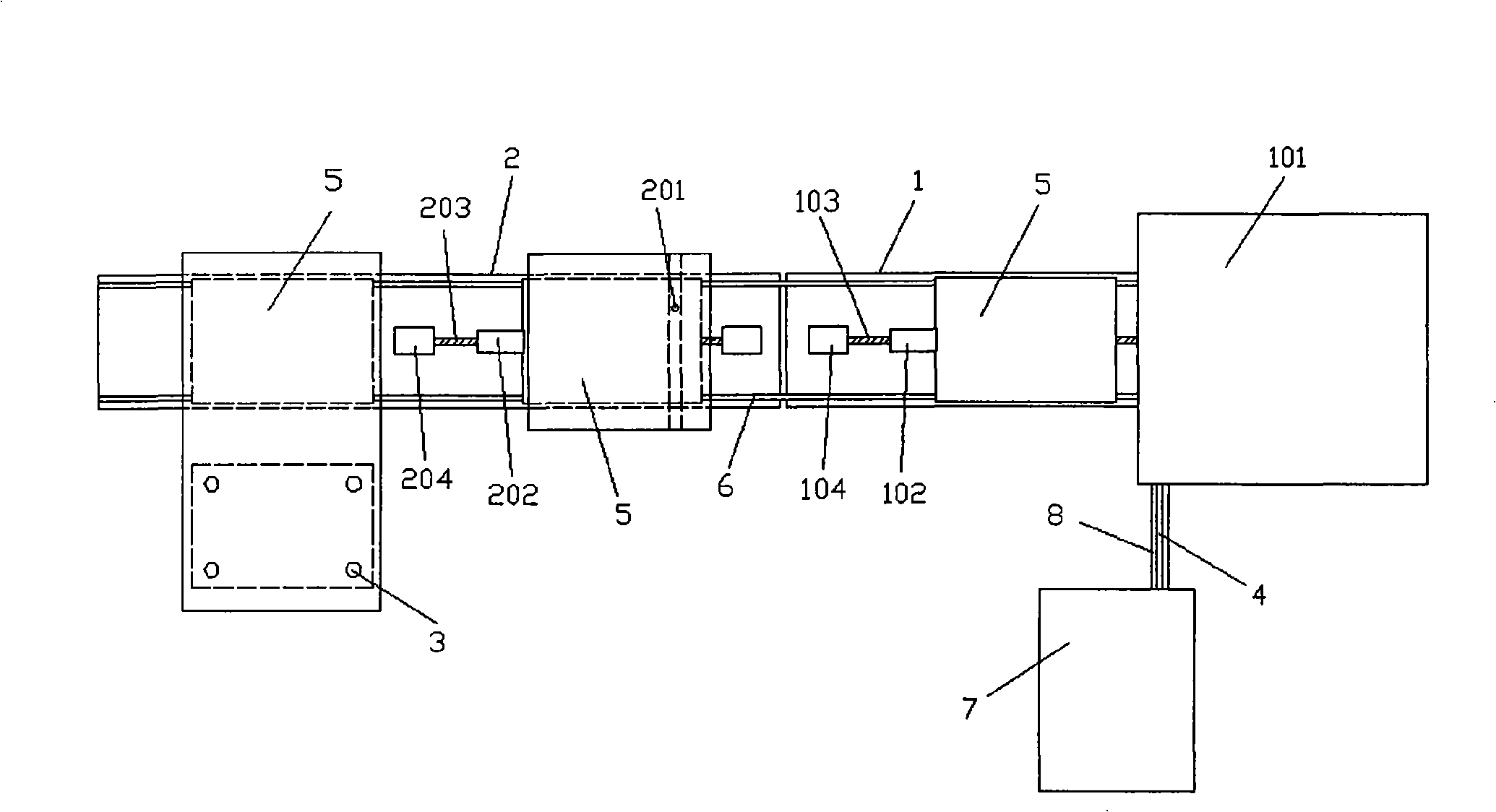

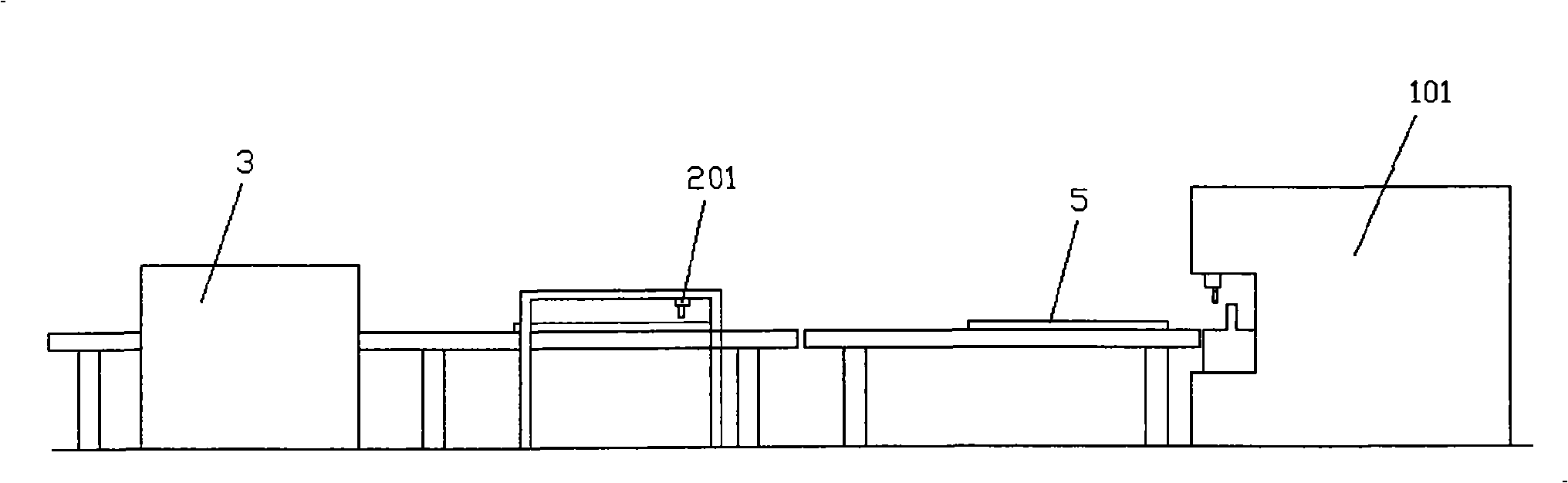

[0044] like figure 1 , 2 Shown is the embodiment of the electrical steel automatic sample preparation system of the present invention, which includes a shearing system 1, a spray printing system 2, a belt conveyor 6, a strapping machine 7, a sheet feeding mechanism 8, and is used to transport a large sample 5 of electrical steel to The suction cup conveyor 3 of the printing system 2.

[0045] The large sample 5 of electrical steel passes through the suction cup conveyor 3, the printing system 2, and the belt conveyor 6 to the shearing system 1 in turn, and is cut into the small sample 4 of electrical steel required for testing. The steel sample 4 is finished product after sheet-feeding mechanism 8 to strapping machine 7 laminations are bundled, and is used for testing.

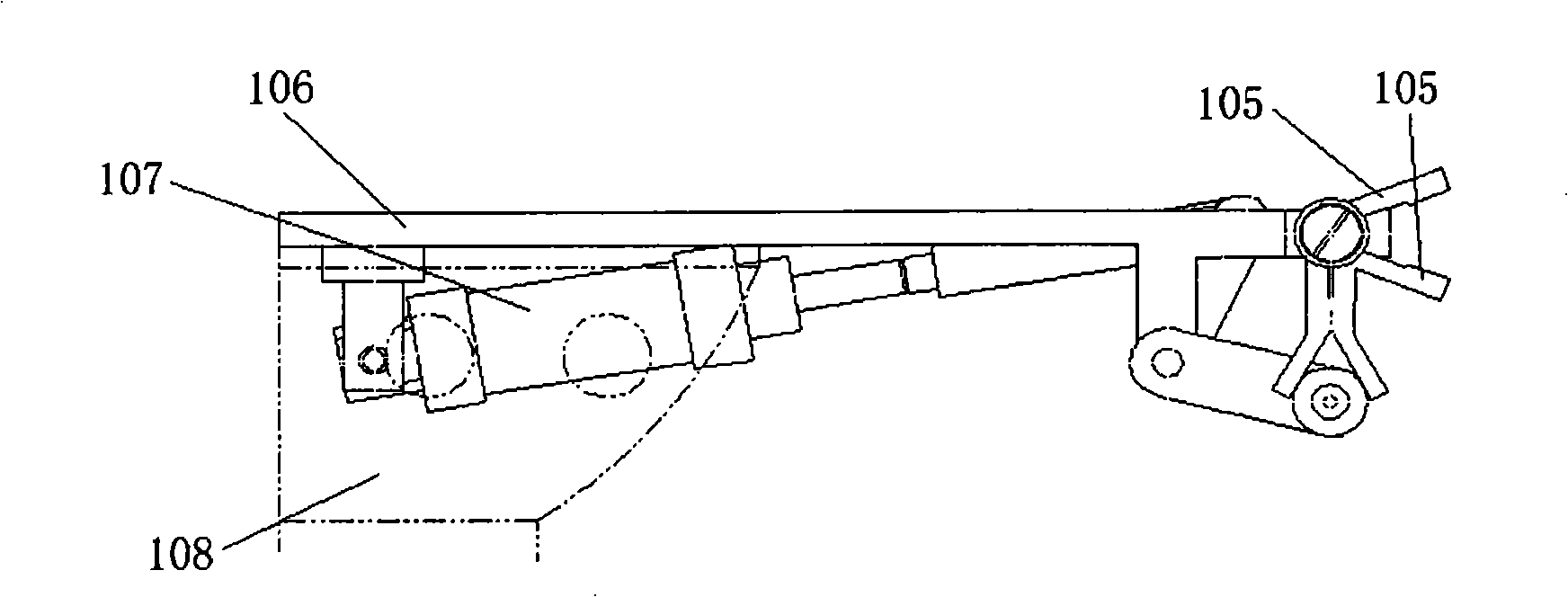

[0046] As shown, the shearing system 1 includes:

[0047] Punch 101 for cutting electrical steel sample 5,

[0048] The first clamp 102 for clamping the electrical steel sample 5,

[0049] a first screw d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com