Method for producing a fuselage cell of an aircraft

A technology of aircraft fuselage and fuselage, applied in the direction of fuselage, aircraft assembly, aircraft floor, etc., can solve problems such as low efficiency and increase technical failures, and achieve the effect of reducing quantity, improving assembly accessibility, and reducing quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

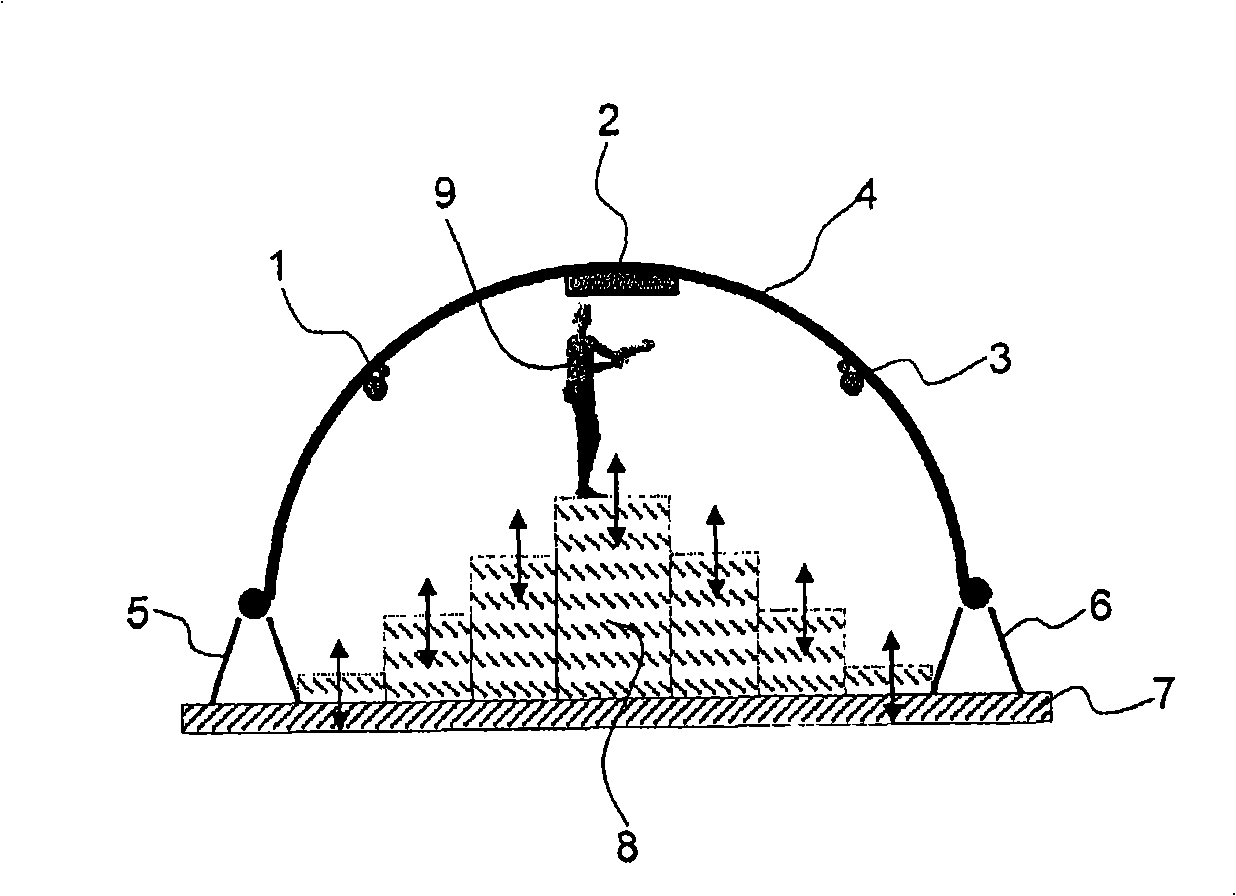

[0031] The following will refer to Figures 1 to 6 , more specifically describe the schematic steps of the method according to the invention by means of an example that may be referred to as a "semi-cylindrical configuration".

[0032] figure 1 The insertion of the technical mounting systems 1 to 3 into the upper housing 4 is shown. Said technical fitting systems 1 to 3 may be, for example, sewage and clean water lines, sanitary installations, air conditioning lines, air supply lines and spent-air lines, power supply lines, electrical and / or light control lines, Hydraulic lines, technical equipment, catering installations, complete catering and sanitary compartments, cabin windows, lighting, safety devices, thermal insulation, etc. In this case, the upper housing 4 is received (supported) by brackets 5 , 6 which in turn are supported on a fixed base 7 . For easier assembly of the technical assembly systems 1 to 3 , the upper housing is “slid over” the working platform 8 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com