Welding process for renovating stainless steel corona dentis in oral cavity

A welding process and stainless steel technology, applied in the field of oral hygiene, can solve the problems of long repair cycle and high medical expenses, and achieve the effects of long repair cycle, solving food jamming, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

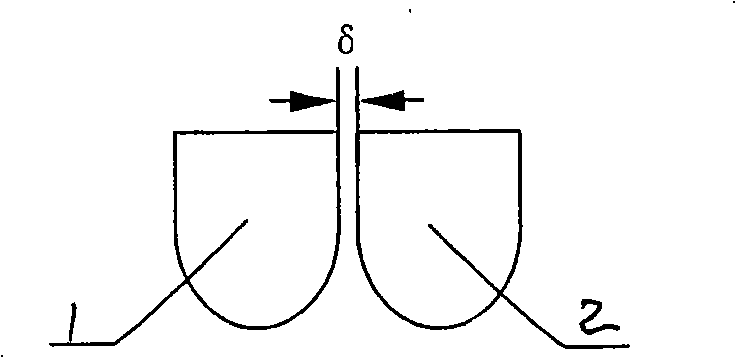

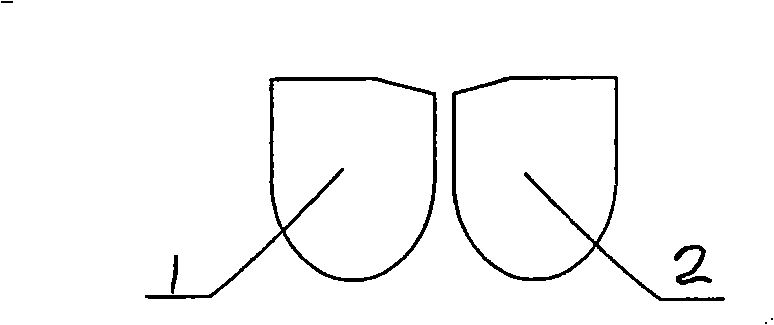

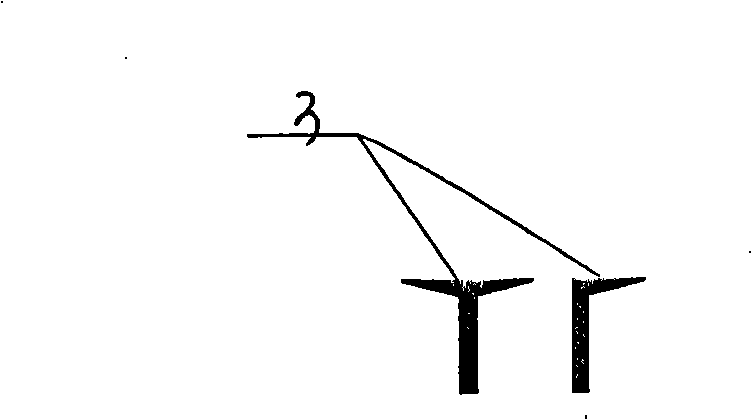

[0019] Below in conjunction with accompanying drawing, the present invention will be further described: gap δ is produced between stainless steel dental crown (1) and adjacent tooth (or stainless steel dental crown) (2), as figure 1 shown. Grind the grooves on the stainless steel crown (1) and the adjacent tooth (or stainless steel crown) (2) on both sides of the gap. According to the situation, the double-sided groove can be ground, and the single-sided groove can also be ground, such as figure 2 shown. Prepare a stainless steel T-shaped stainless steel insert (3) of suitable size for double-sided bevelling, or an L-shaped stainless steel insert (3) for single-sided bevelling, such as image 3 shown. The negative pole (5) of the welding power supply of the capacitor energy storage welding machine (4) is clamped on the stainless steel crown (1) with a large contact area, and the positive pole is connected to the welding pen (6). The pen tip is made of silver and silver all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com