Current transformer for power supply and method for manufacturing the same

A converter and power supply technology, which is applied in the manufacture of inductors/transformers/magnets, transformers, inductors, etc., can solve the problems of increasing the overall size of the converter for power supply, increasing manufacturing costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Reference will now be made in detail to the preferred embodiments of the invention, examples of which are illustrated in the accompanying drawings.

[0053] Hereinafter, the power converter and its manufacturing method will be described in more detail.

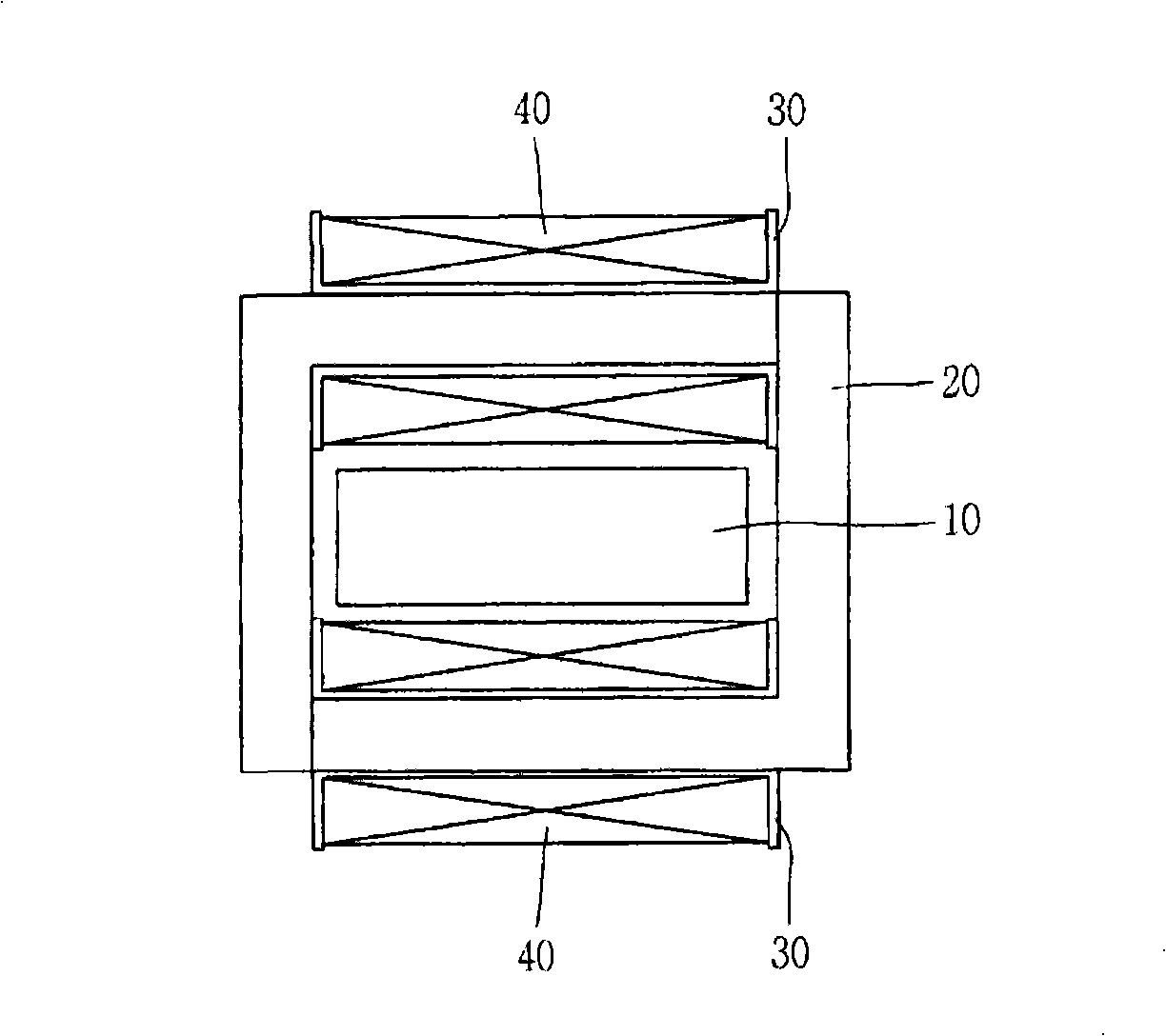

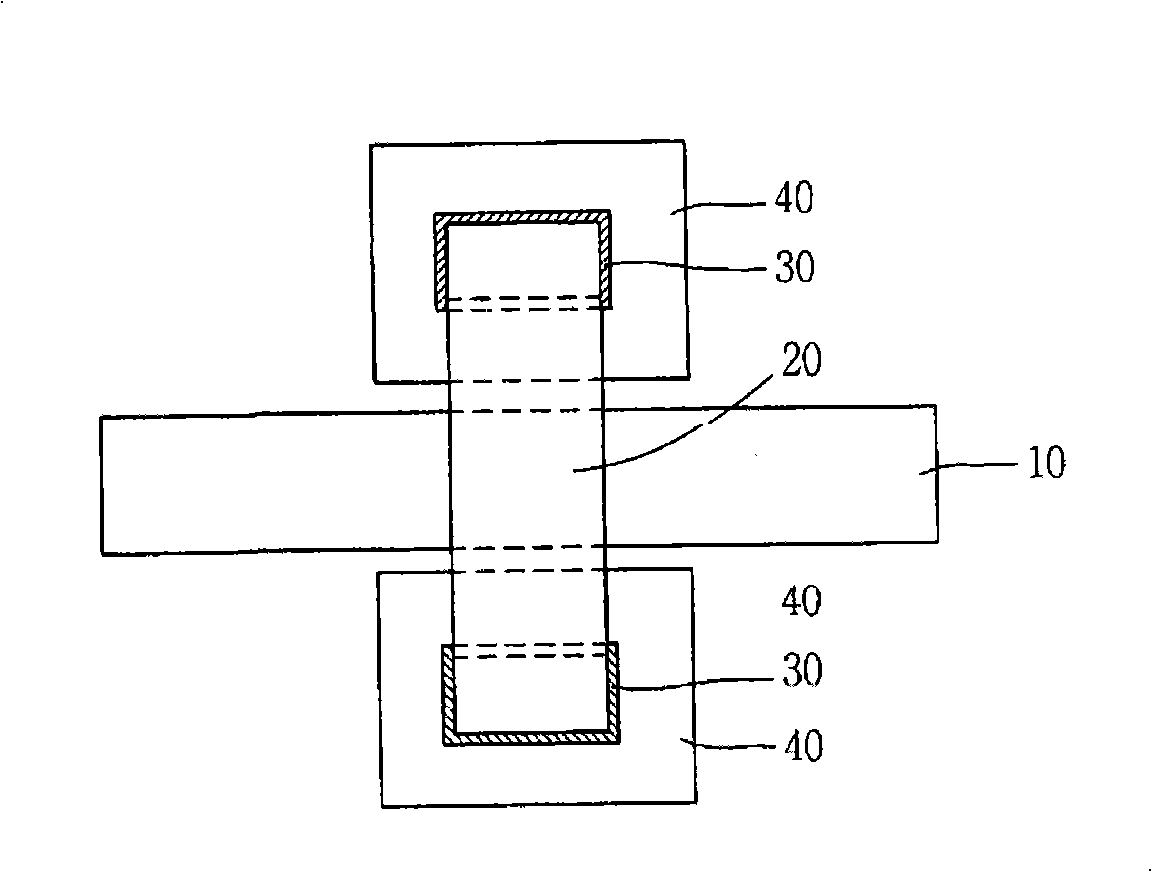

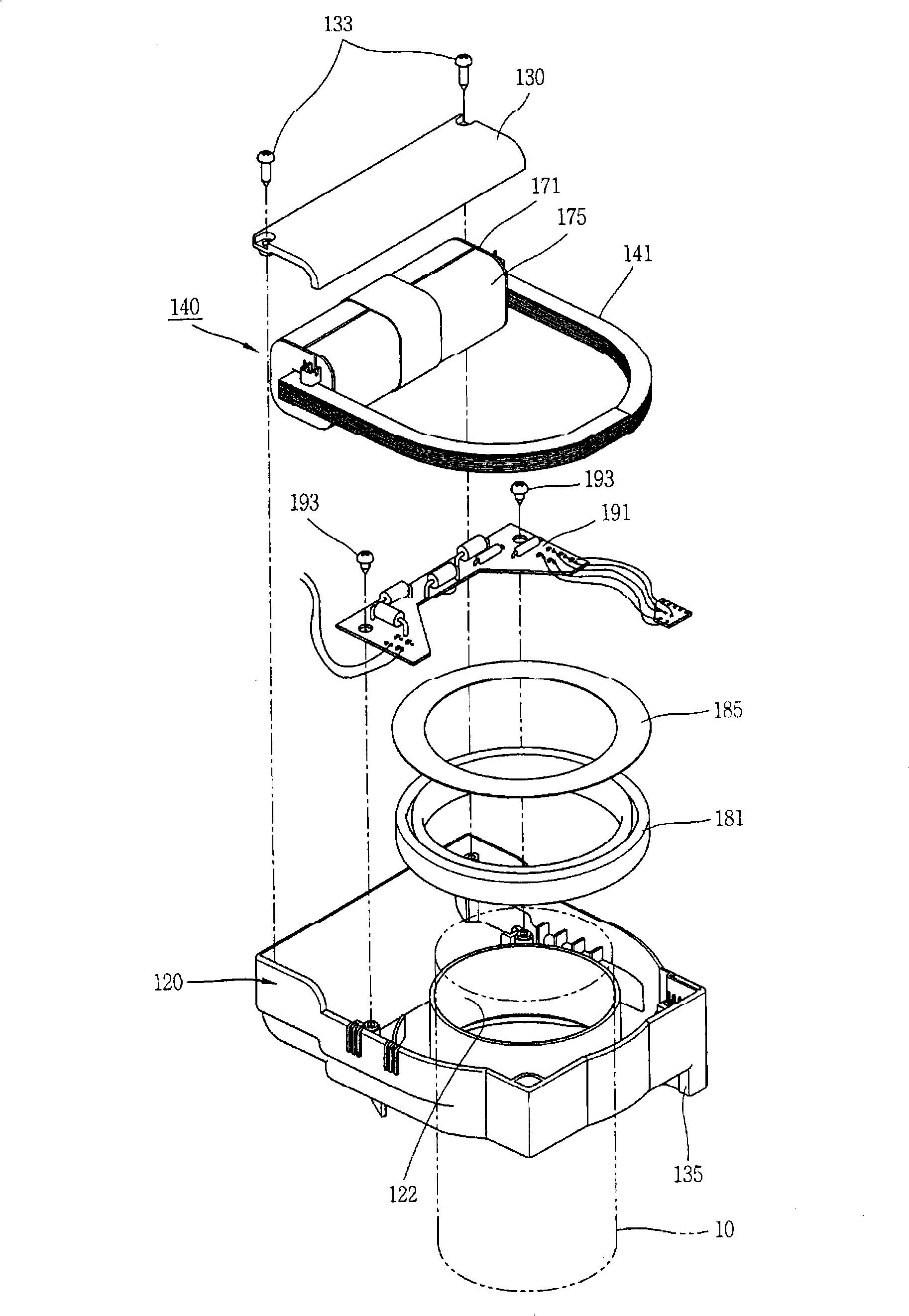

[0054] Such as Figures 3 to 5 As shown, the power converter includes: a casing 120 having an accommodation space therein; a power supply part 140 for supplying a current induced by a primary conductor 110 to a power supply object such as an overcurrent relay (OCR); a current measurement a part 181 for measuring the current flowing on the primary conductor 110; and a printed circuit board (PCB) 191 connected to the power supply part 140 and the current measuring part 181, respectively.

[0055] A primary conductor joining portion 122 for joining the primary conductor 110 is formed at the housing 120 . Also, a current measuring part 181 implemented as a circular Rogowski coil is arranged around the primary conductor ju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com