Processing method after positive plate formation of accumulator

A positive plate and storage battery technology, applied in the direction of electrode manufacturing, etc., can solve the problems of poor dry charging performance of the battery, passivation of the positive plate, and long production time, and achieve the effects of small discharge voltage drop, improved production efficiency, and quick results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

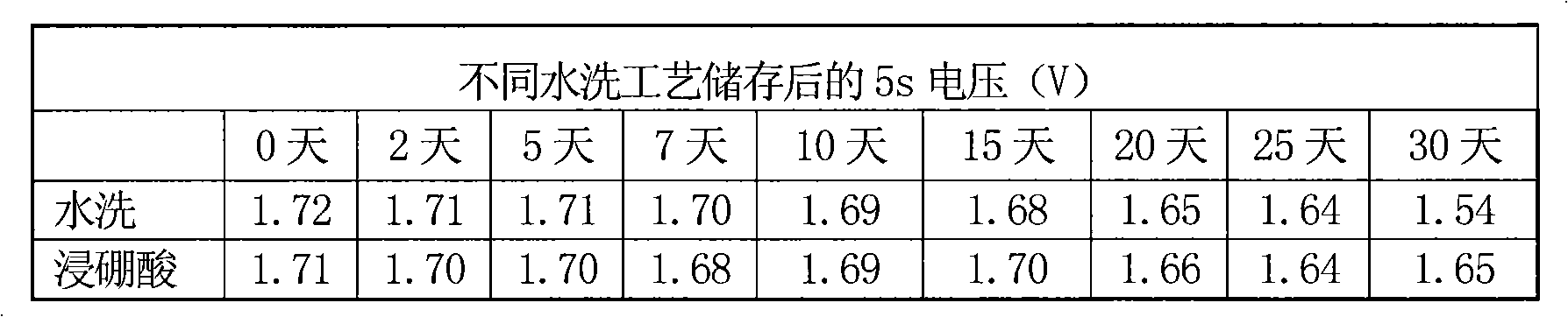

Embodiment 1

[0013] Embodiment 1: add 100kg tap water in the water tank, take by weighing 500g of industrial boric acid and add in the water tank and stir to make it fully dissolve, be mixed with 0.5% boric acid solution, take 170 large pieces (about one shelf plate) of the positive plate just out of the chemical formation tank Soak for 10 minutes and take out the drying line; add 15kg of tap water and 70g of boric acid, take 170 large pieces of positive plates that have just come out of the chemical formation tank and soak for 12 minutes, then take them out of the drying line; add 15kg of tap water and 70g of boric acid The positive plate 170 of the tank was soaked for 12 minutes and then taken out of the drying line; after the above operation was repeated 10 times, the boric acid solution was turbid due to the phenomenon of powder falling off the positive plate, which affected the treatment effect, so the boric acid solution was released and a new one was prepared. Boric acid solution con...

Embodiment 2

[0014] Example 2: Add 100kg of tap water to the water tank, weigh 2000g of industrial boric acid, add it to the water tank and stir to make it fully dissolve, and prepare a 2% boric acid solution. Take 180 large pieces of positive plates that have just come out of the chemical formation tank and soak them for 10 minutes. Take out the drying line Add 15kg of tap water and 300g of boric acid, soak 180 large pieces of positive plates that have just come out of the tank for 10 minutes and then take them out of the drying line; add 15 kg of tap water and 300g of boric acid, and soak 180 large pieces of positive plates that have just come out of the tank After 10 minutes, take out the drying line; after the above operation is repeated 10 times, a new boric acid solution is prepared to continue production.

Embodiment 3

[0015] Example 3: Add 100kg of tap water to the water tank, weigh 3000g of industrial boric acid, add it to the water tank and stir to make it fully dissolve, and prepare a 3% boric acid solution, soak 190 large pieces of positive plates just out of the chemical formation tank for 11 minutes and take them out of the drying line Add 15kg of tap water and 450g of boric acid, soak 190 large pieces of positive plates that have just come out of the tank for 11 minutes and then take them out of the drying line; add 15 kg of tap water and 450g of boric acid, and soak 190 large pieces of positive plates that have just come out of the tank After 11 minutes, take out the drying line; after the above operation is repeated 10 times, a new boric acid solution is prepared to continue production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com