Solid laser device for simultaneously outputting red, yellow and green light and its laser generation method

A simultaneous output and solid-state laser technology, applied in the field of lasers, can solve the problems of expensive periodically polarized crystals, high transmittance and coating requirements, and low power density, and achieve compact structure, good spatial coherence, and high conversion efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

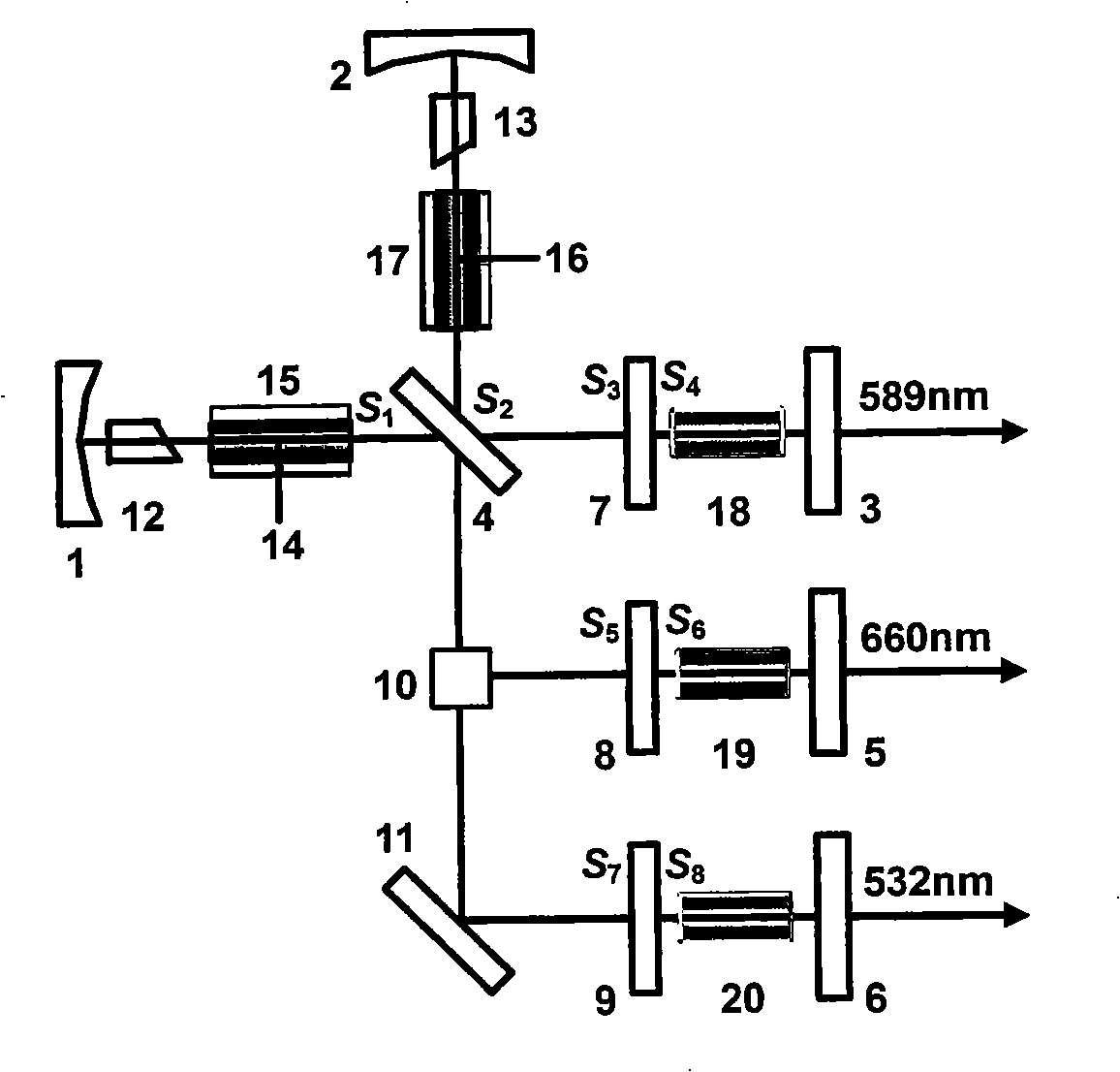

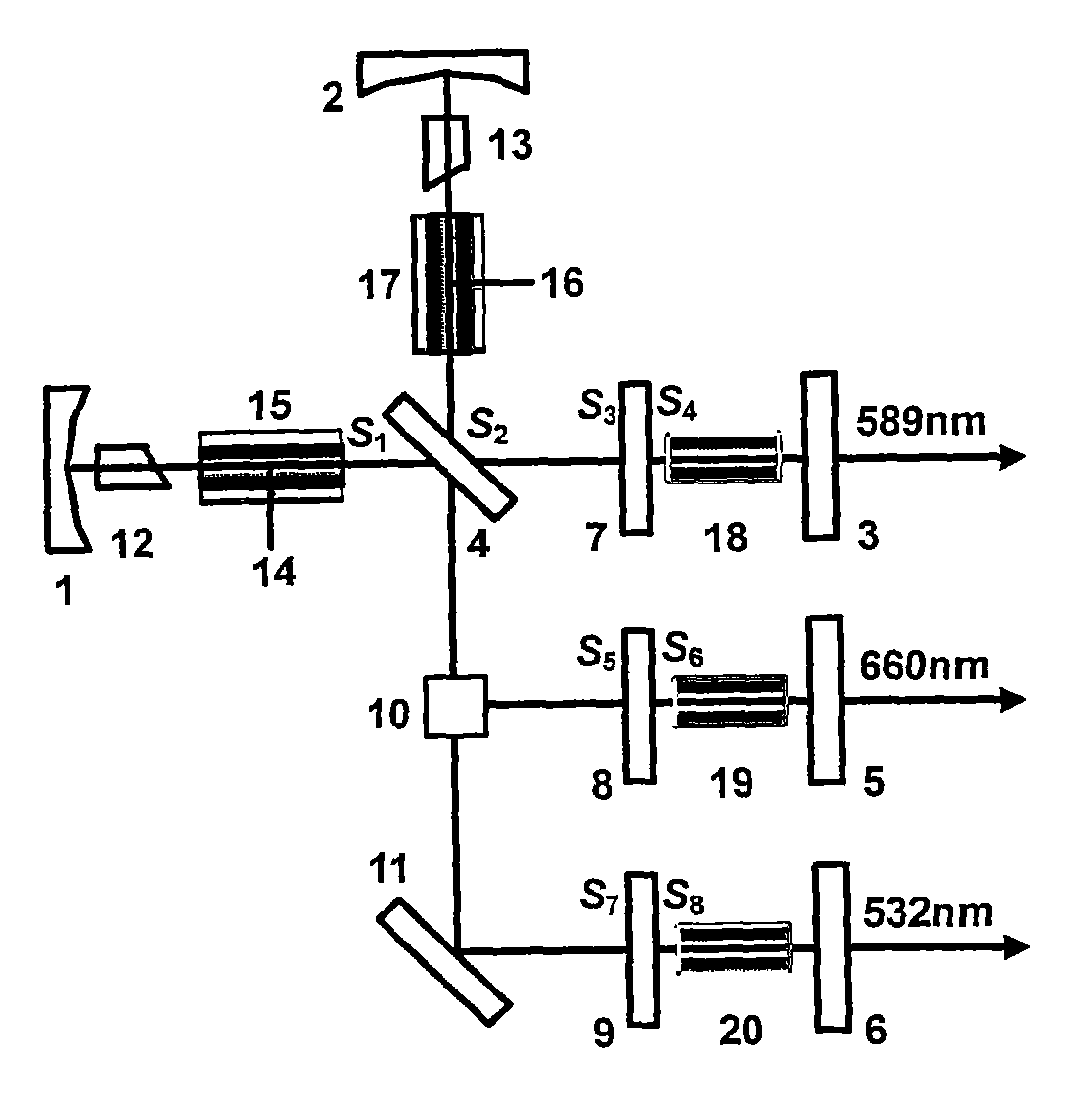

[0037] figure 1 Side-pump Nd for LD 3+ : YAG simultaneously outputs three-wavelength visible light laser device of 660nm red light, 532nm green light and 589nm yellow light. The first plano-concave total reflection end mirror 1 of the device and the first plane reflection end mirror 3 and the third plane reflection end mirror 6 respectively form a 1064nm "P" polarization and "S" polarization resonator; the second plan-concave total reflection end mirror 2 and the first plane reflection end mirror 3 and the second plane reflection end mirror 5 respectively form 1319nm "S" polarization and "P" polarization resonators. A first acousto-optic Q-switched crystal 12, a first Nd:YAG laser crystal 14, a first polarization beam splitter 4, and a first harmonic mirror 7 are sequentially arranged on the horizontal optical path incident on the first plano-concave total reflection end mirror 1. , Sum frequency crystal 18 and first plane reflection end mirror 3; the side of the optical path ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com