Electric top spiral spoke nut

A spiral and electric technology, applied in the direction of lifting devices, can solve the problems of expensive processing technology and cost, high motor working current, small structural current, etc., and achieve the effect of preventing accidental breakage, reducing working current and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

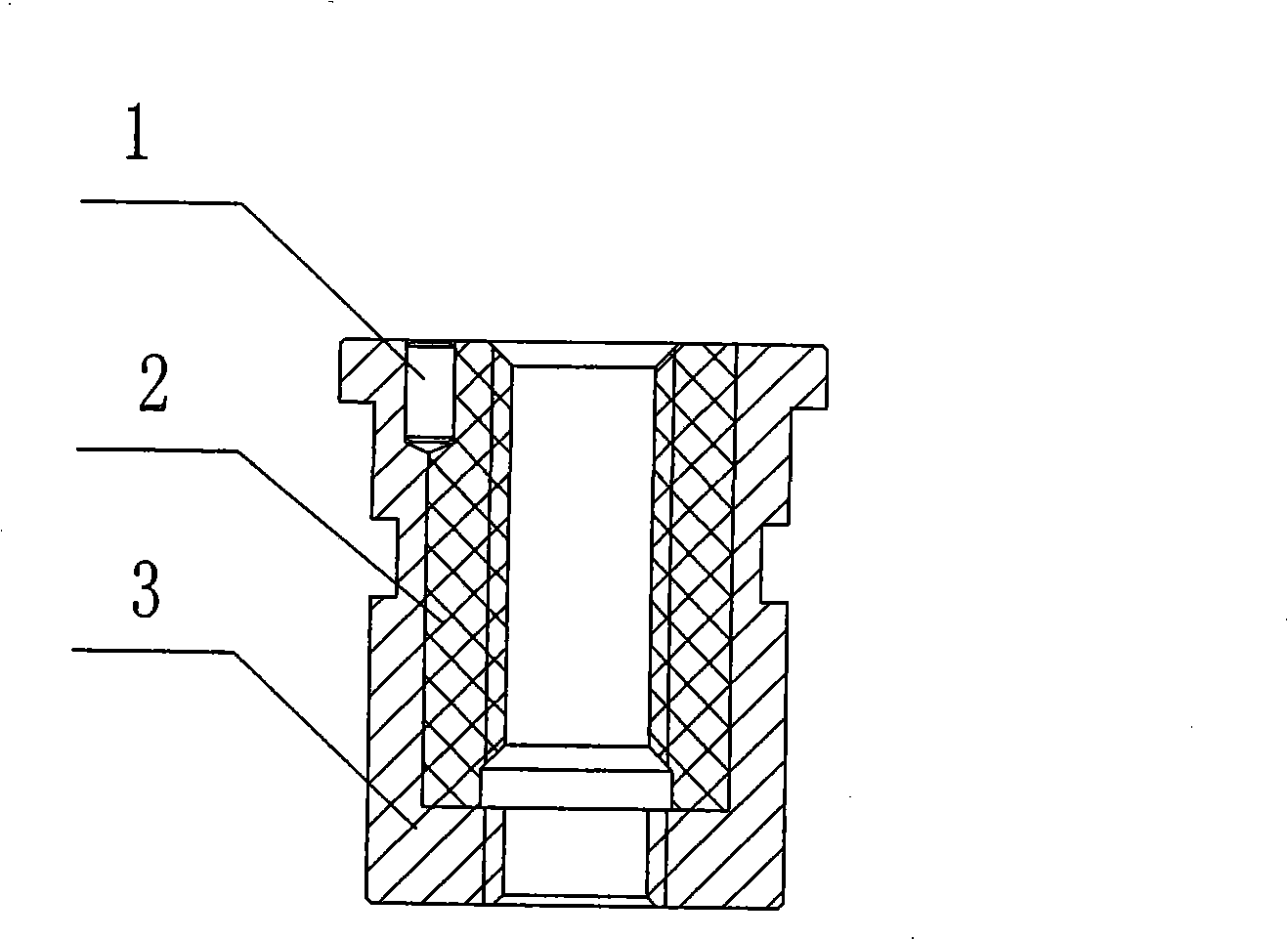

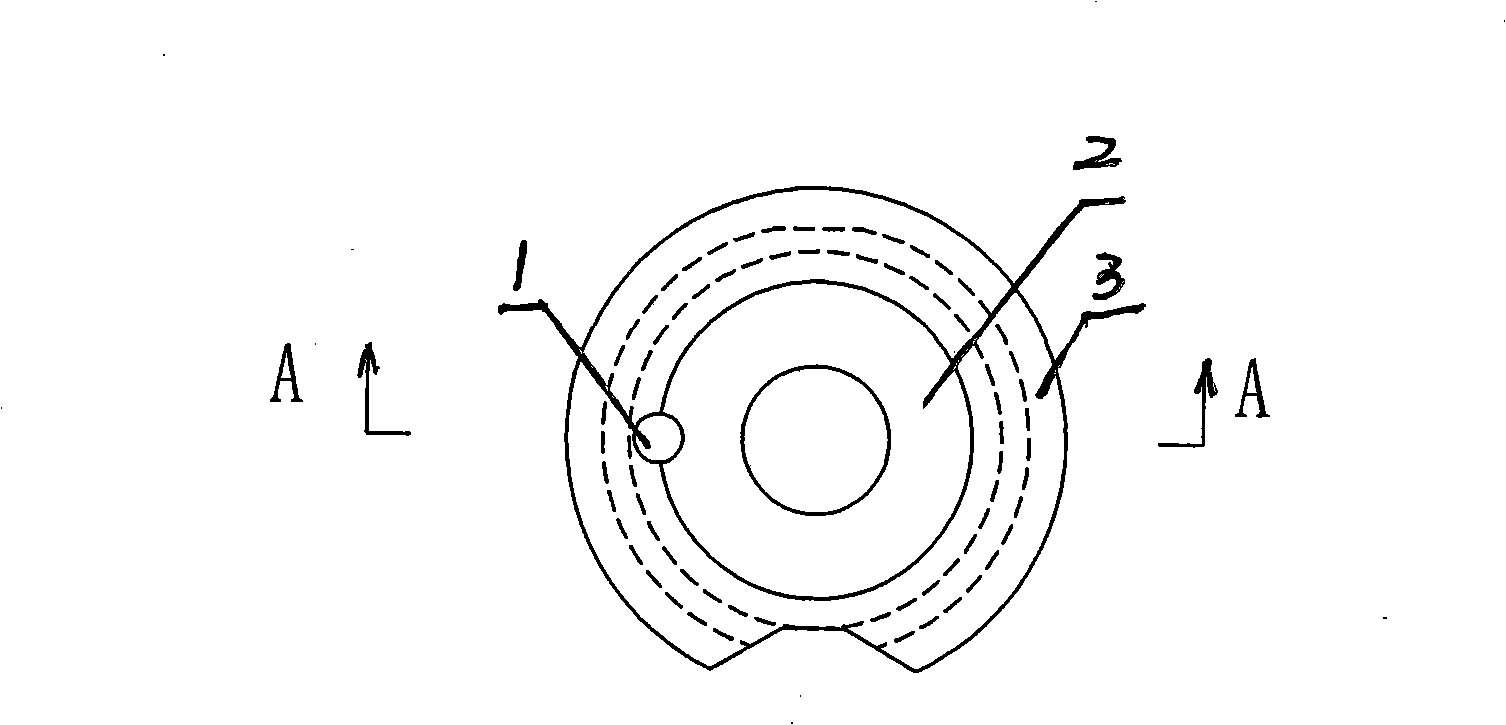

[0011] Embodiment 1: A kind of electric top helical width nut of this embodiment, such as figure 1 , figure 2 As shown, it is formed by the tight fit of the outer threaded sleeve 3 and the inner nut 2, and a fixed pin 1 is installed between the inner nut 2 and the outer threaded sleeve 3, and the fixed pin 1 is used to further fix the connection between the inner nut 2 and the outer threaded sleeve 3 . The material of the outer threaded sleeve 3 is iron, and the material of the inner nut 2 is MC nylon. After using this material, the abrasion is reduced, and the working current of a single motor is guaranteed to be small.

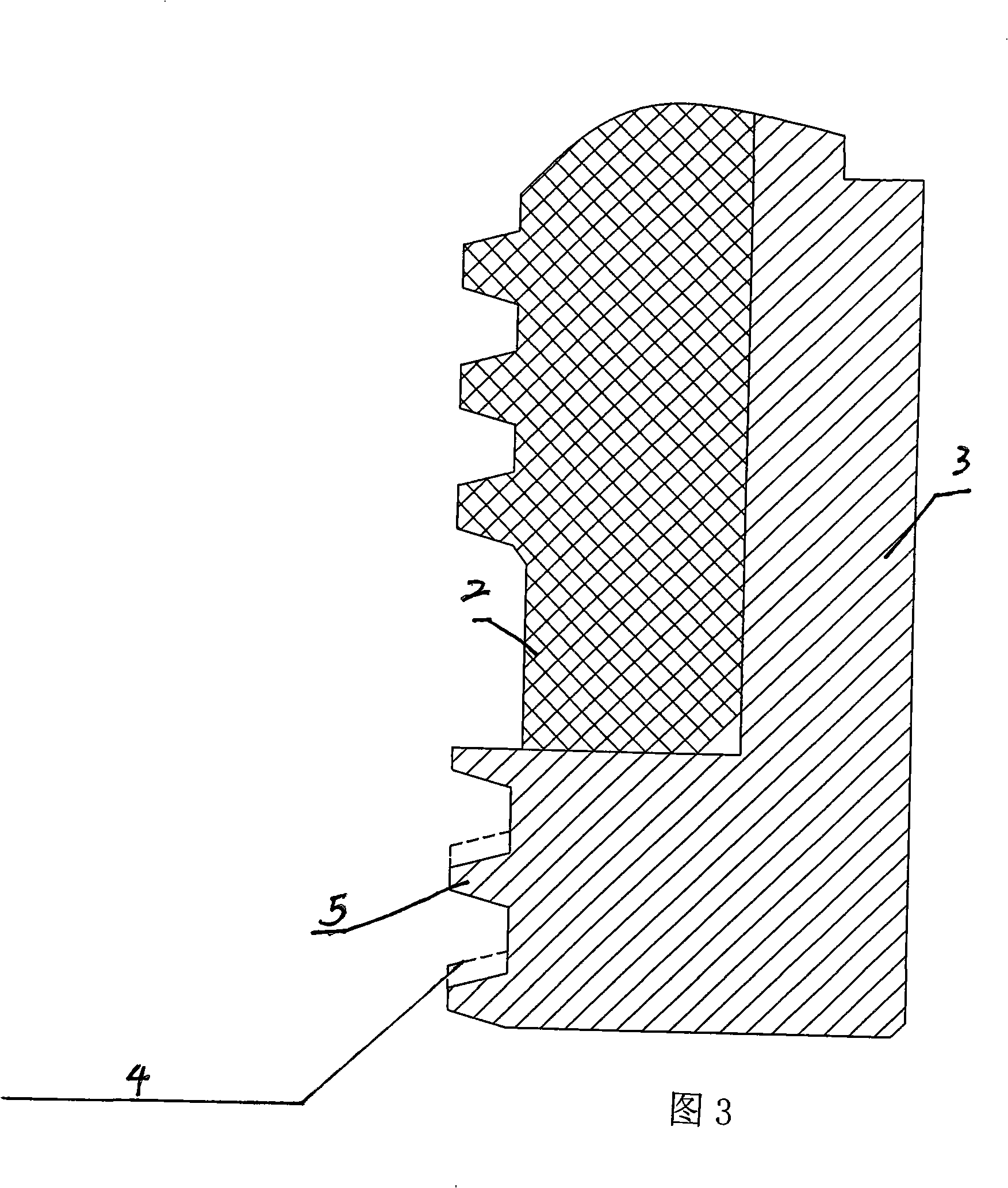

[0012] As shown in FIG. 3 , the thread 5 at the joint between the outer threaded sleeve 3 and the screw rod is a half profile. Compared with the thread on the inner nut 2, the thread on the outer threaded sleeve 3 has removed half the thickness of the thread 4 above, so that there is a gap between the outer threaded sleeve 3 and the screw rod, preventing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com