Method for preparing benzalcohol by hydrogenation of hydrogen peroxide cumene

A technology for preparing cumene hydrogen peroxide and benzyl alcohol, which is applied in chemical instruments and methods, isomerization preparation, hydroxyl compound preparation, etc., can solve problems such as poor industrial practicability, harsh operation skills, and difficulty in treating wastewater. , to avoid pollution and solve stability problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0054] Example

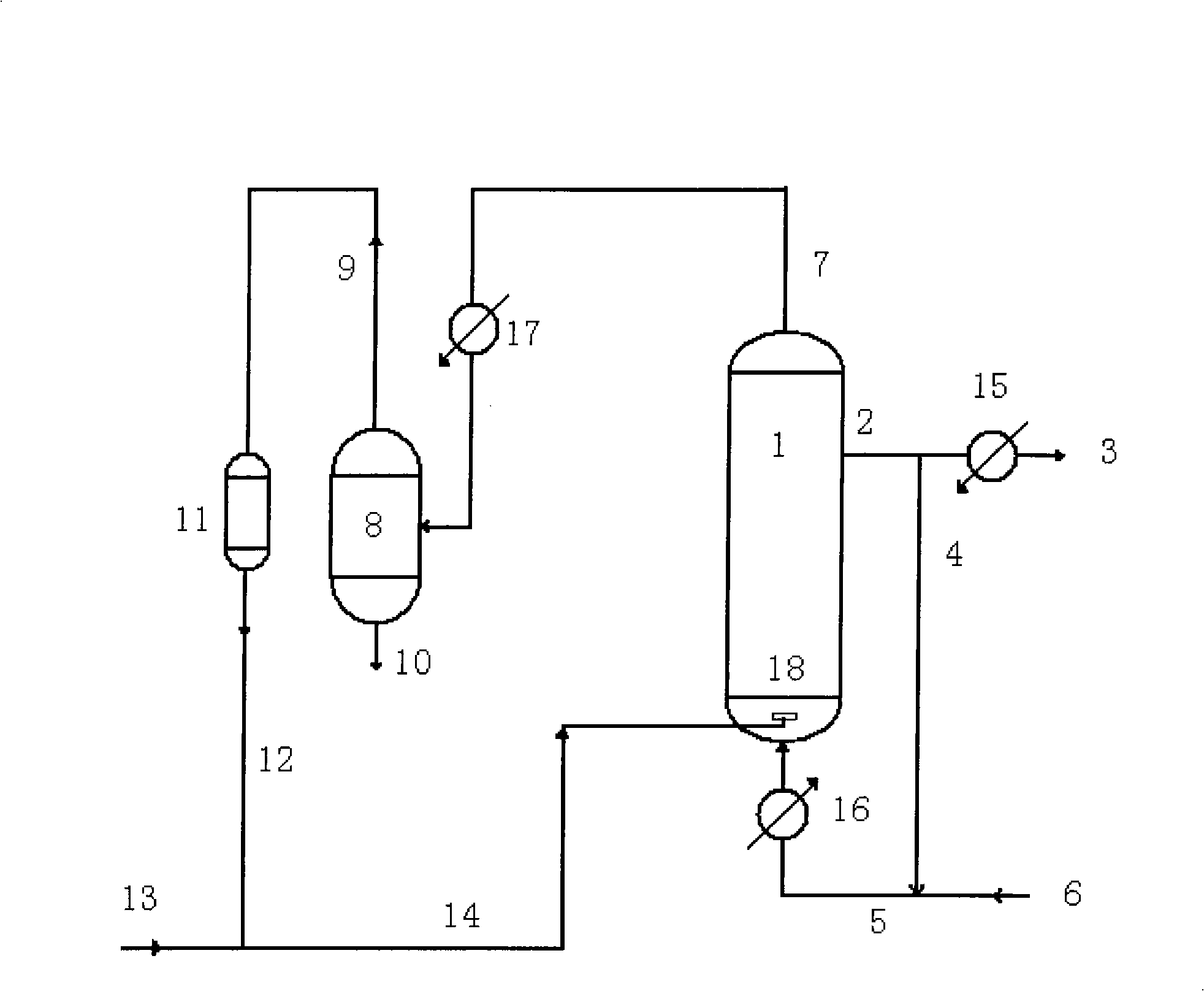

[0055] Combine the process of the present invention figure 1 The production process is described as follows:

[0056] The reaction raw material from line 6 is mixed with the circulating material from circulating line 4 in the fluidized bed reactor, and then enters the material heater 16 through line 5, where it is heated to 30-50°C and then enters the fluidized bed reactor 1. The new hydrogen sent from line 13 is mixed with the circulating hydrogen sent from line 12 and then enters into hydrogen heater 19 through line 14, where it is heated to 30-50°C and then enters into gas distribution 18, and then enters after being distributed by gas distributor To the reaction zone of fluidized reactor 1. A hydrogenation catalyst is installed in the reactor 1, and the hydrogenation reaction is carried out under suitable reaction conditions. The reacted liquid comes out of line 2, a part of the liquid is circulated back to reactor 1 through line 4, and the other part is sent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com