Method for measuring non-protein nitrogen content in tobacco

A determination method, non-protein technology, applied in the measurement of color/spectral characteristics, etc., can solve the problem of large errors, achieve the effect of fewer steps and reduce operating errors

Inactive Publication Date: 2009-01-21

CHINA TOBACCO GUANGDONG IND

View PDF0 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the determination process of this method, after digesting the precipitate, it is necessary to re-collect the ammonia released by strong alkali dist

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

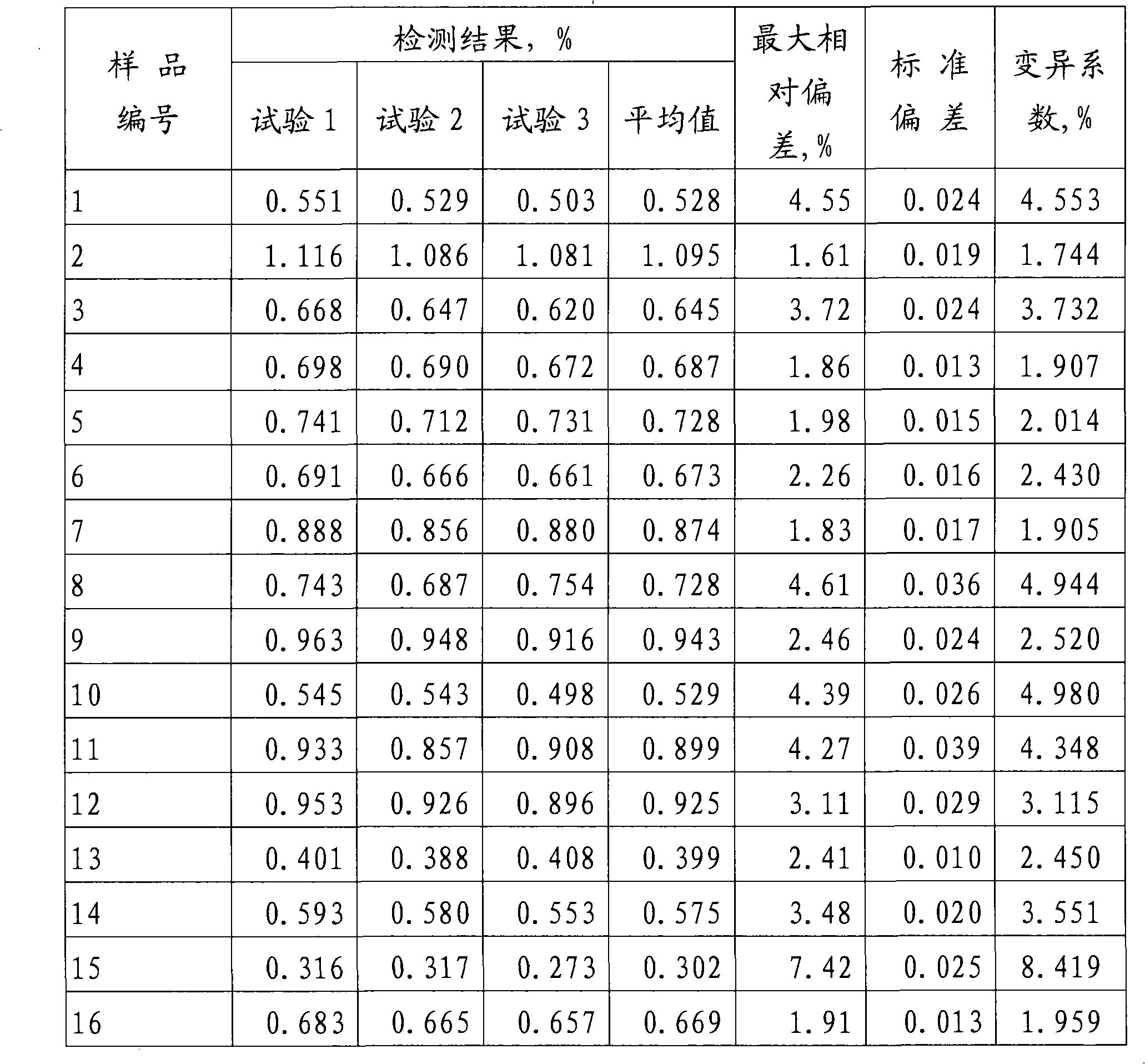

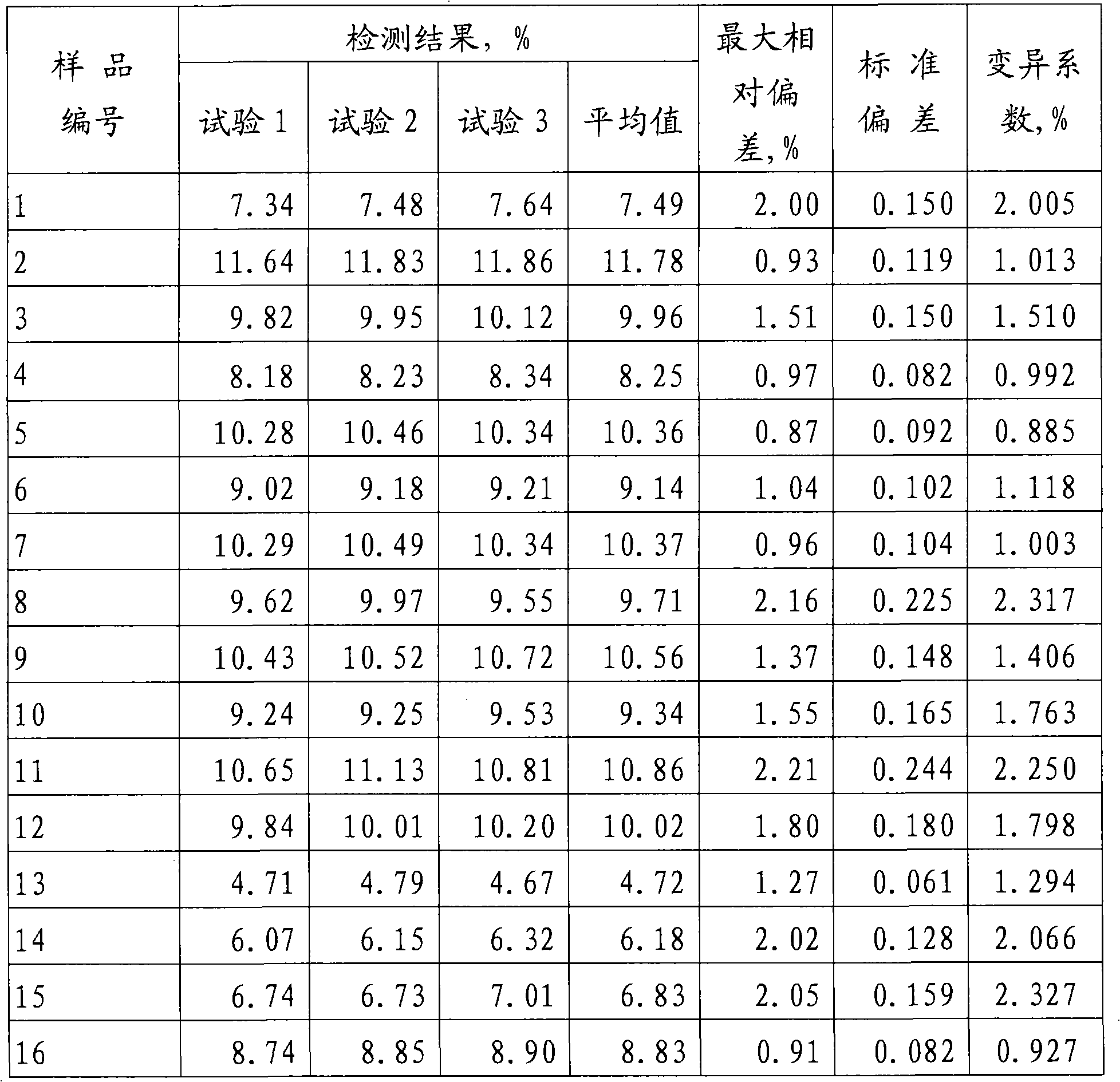

The invention discloses a method for measuring the content of nonprotein nitrogen in tobacco, which comprises the following steps: firstly, weighing tobacco, secondly, putting the tobacco which is weighed in enough acid or copper sulfate solution with a certain concentration, heating some time till proteins are fully solidified, thirdly, filtering after the proteins are fully solidified, and flushing matters which are filtered by acid or copper sulfate solution in the step two, fourthly, combing filtrate and doing constant volume, fifthly, getting a certain amount of filtrate to do digestion treatment, and doing constant volume, sixthly, doing digestion treatment which is the same to the step four for ammonium salt standard solution, and doing constant volume, seventhly, comparing the color of the filtrate which is got from the step five and the liquid after doing constant volume of the step seven, and getting the content of nitrogen in the filtrate, wherein the step seven has no order with the step one to the step five. The measuring method has little steps, which reduces artificial operating errors, and is a simple and high-effective measuring method.

Description

technical field [0001] The invention relates to a method for testing components in tobacco, in particular to a method for measuring non-protein nitrogen content in tobacco. Background technique [0002] The content of each component in tobacco determines the quality of tobacco. For example, the ratio of tar to nicotine in mixed cigarettes is 11:1, while that of flue-cured tobacco is mostly 13-14:1. Therefore, compared with flue-cured cigarettes, mixed cigarettes have the largest The advantage is that the aroma is sufficient and the tar content is low. Tobacco contains protein, which will increase the bitterness of the smoke after burning, resulting in a spicy and irritating taste, so the protein has a bad effect on the smoking taste of cigarettes, but if the protein content is too low, the smoke will appear flat and tasteless And the aroma will also deteriorate. In addition, protein can be hydrolyzed into amino acids during the preparation process, and the content of amino...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N21/25

Inventor 孔浩辉黄菲

Owner CHINA TOBACCO GUANGDONG IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com