Hot rolling high reaming steel plate having 440MPa grade of tensile strength and manufacturing method thereof

A technology of tensile strength and manufacturing method, applied in the direction of metal rolling, manufacturing tools, metal rolling, etc., to achieve good hole expansion performance, cost reduction, and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

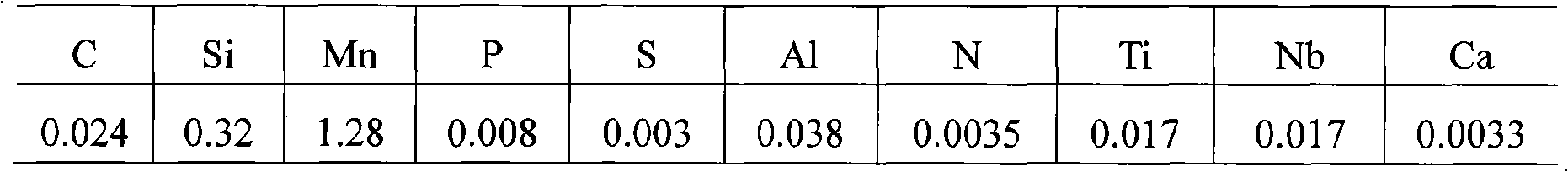

[0037] Through smelting, casting, hot rolling and cooling processes, the finished steel with the chemical composition described in the following table 1 is obtained, with a thickness of 3mm, and then the mechanical performance test (according to the GB6397-86 standard) and the hole expansion performance test (JFST1001-1996 standard conduct). The rolling process parameters, mechanical properties, and hole expansion properties are shown in Table 11 below.

[0038] The chemical composition (wt%) of table 1 embodiment 1 steel

[0039]

Embodiment 2

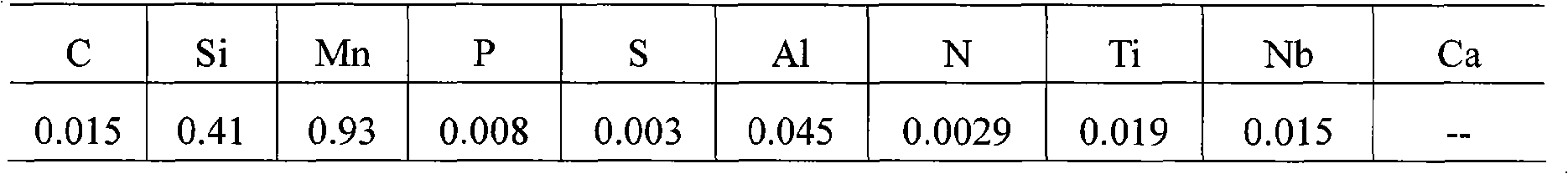

[0041] Through smelting, casting, hot rolling and cooling processes, the finished steel with the chemical composition described in the following table 2 is obtained, the thickness is 3mm, and then the mechanical performance test (according to the GB6397-86 standard) and the hole expansion performance test (JFST1001-1996 standard conduct). The rolling process parameters, mechanical properties, and hole expansion properties are shown in Table 11 below.

[0042] Chemical composition (wt%) of steel of table 2 embodiment 2

[0043]

Embodiment 3

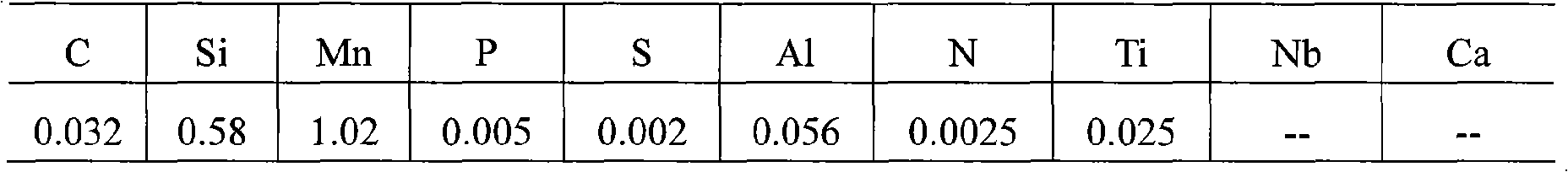

[0045] Through smelting, casting, hot rolling and cooling processes, the finished steel with the chemical composition described in the following table 3 is obtained, the thickness is 3mm, and then the mechanical performance test (according to the GB6397-86 standard) and the hole expansion performance test (JFST1001-1996 standard conduct). The rolling process parameters, mechanical properties, and hole expansion properties are shown in Table 11 below.

[0046] Chemical composition (wt%) of table 3 embodiment 3 steel

[0047]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com