Centrifugal pump suitable for high temperature and high coagulating point medium and its use method

A high freezing point, centrifugal pump technology, which is applied to components of pumping devices for elastic fluids, pumps for special fluids, pumps, etc., can solve problems that affect the working quality of centrifugal pumps, and are easy to solidify, so as to improve the working life. The effect of avoiding solidification and avoiding leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

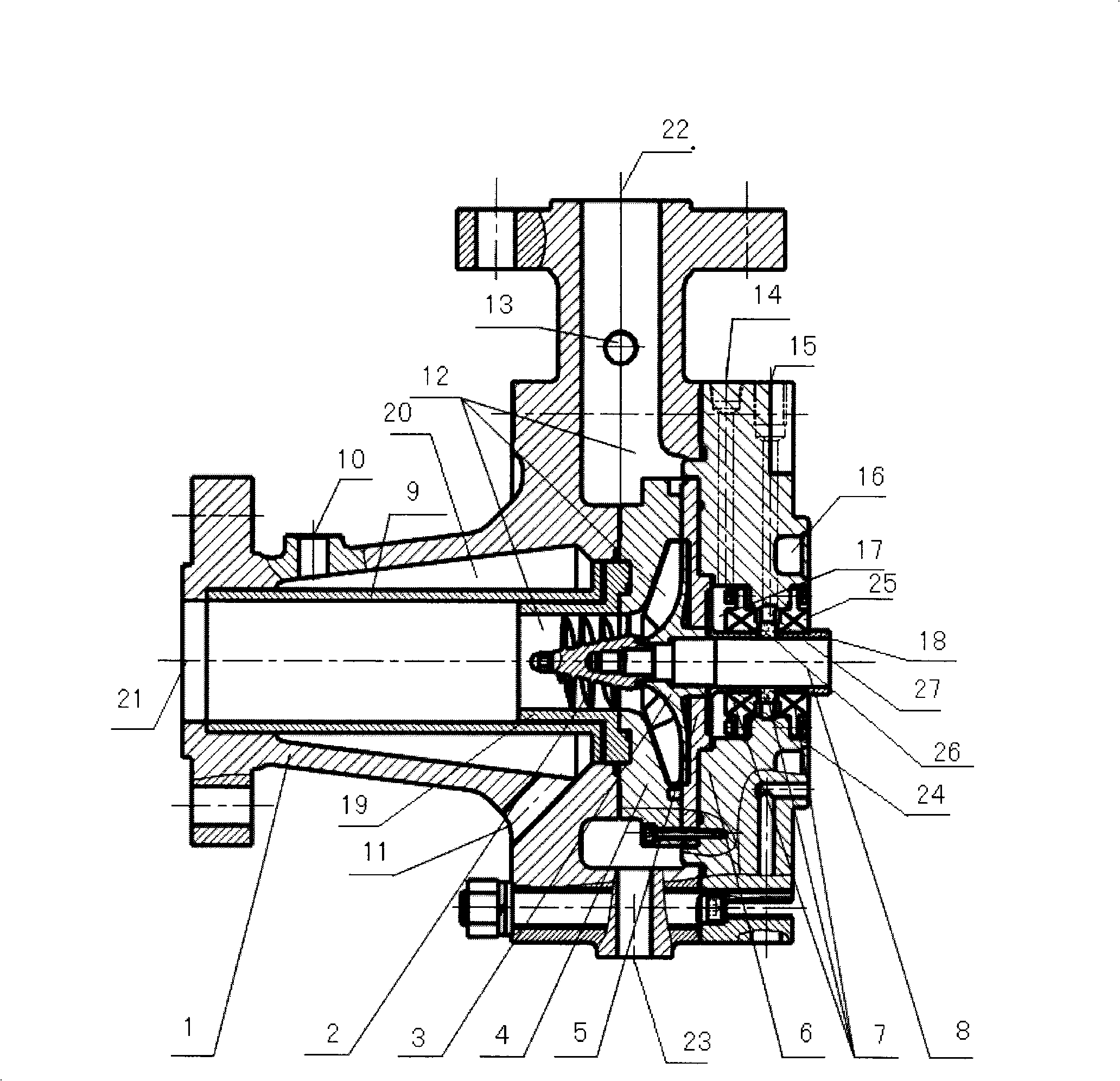

[0014] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

[0015] like figure 1 As shown, a centrifugal pump suitable for medium with high temperature and high freezing point includes a pump casing 1, a pump cover 6 and a pump shaft 8. The pump casing 1 is connected to the pump cover 6 by bolts and sealed by a sealing ring. Inside the pump casing 1, a sleeve-shaped steam insulation jacket 9 is provided along the direction of the medium inlet 21, and a steam insulation chamber 20 is formed between the outside of the steam insulation jacket 9 and the inner wall of the pump casing 1. The pump casing 1 is provided with a pump casing steam insulation inlet 10 and a pump casing steam insulation inlet 11 communicating with the steam insulation chamber 20, and a liner 5 is provided between the pump casing 1 and the pump cover 6, and the liner 5 is connected to the pump by screws. Cover 6. The pump shaft 8 extends into the pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com