Refrigerant charging and pouring seal device and seal method

A sealing device and refrigerant technology, which is applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve problems such as use restrictions, and achieve the effect of simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The invention adopts a charging pipe with an internal thread at the mouth of the pipe. After filling, the filling pipe is flattened and the filling pipe mouth is sealed with bolts to realize sealing. The device and method provided by the present invention do not need to use flame to melt and seal the filling port, so as to prevent the high-temperature flame from decomposing the leaked Freon refrigerant into toxic gas or igniting the flammable refrigerant.

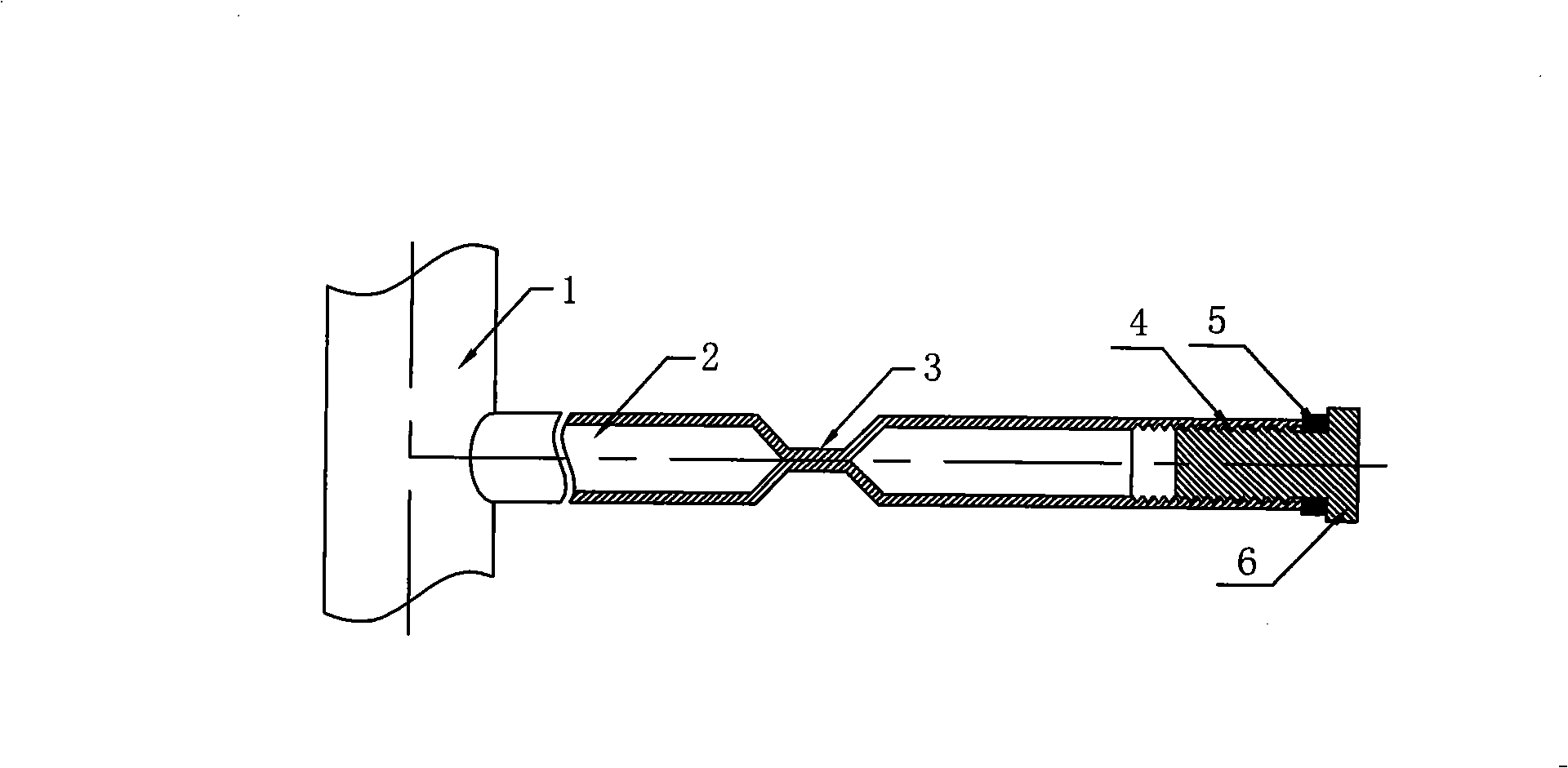

[0014] like figure 1 As shown, the refrigerant charging and sealing device provided by the present invention includes a refrigeration pipeline 1 and a charging pipe 2, wherein the charging pipe 2 is provided with a flattened mouth 3, and the end of the charging pipe 2 is provided with an internal thread, and the sealing The bolt 6 cooperates with the internal thread and is arranged at the end of the charging pipe 2. A sealing washer 5 is arranged between the nail cap of the sealing bolt 6 and the end of the charging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com