Preparation method for LED and tool for preparing the LED

A technology of light-emitting diodes and fixtures, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problems of complicated steps and cost of materials, so as to reduce the manufacturing process, reduce the manufacturing process, and reduce the manufacturing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

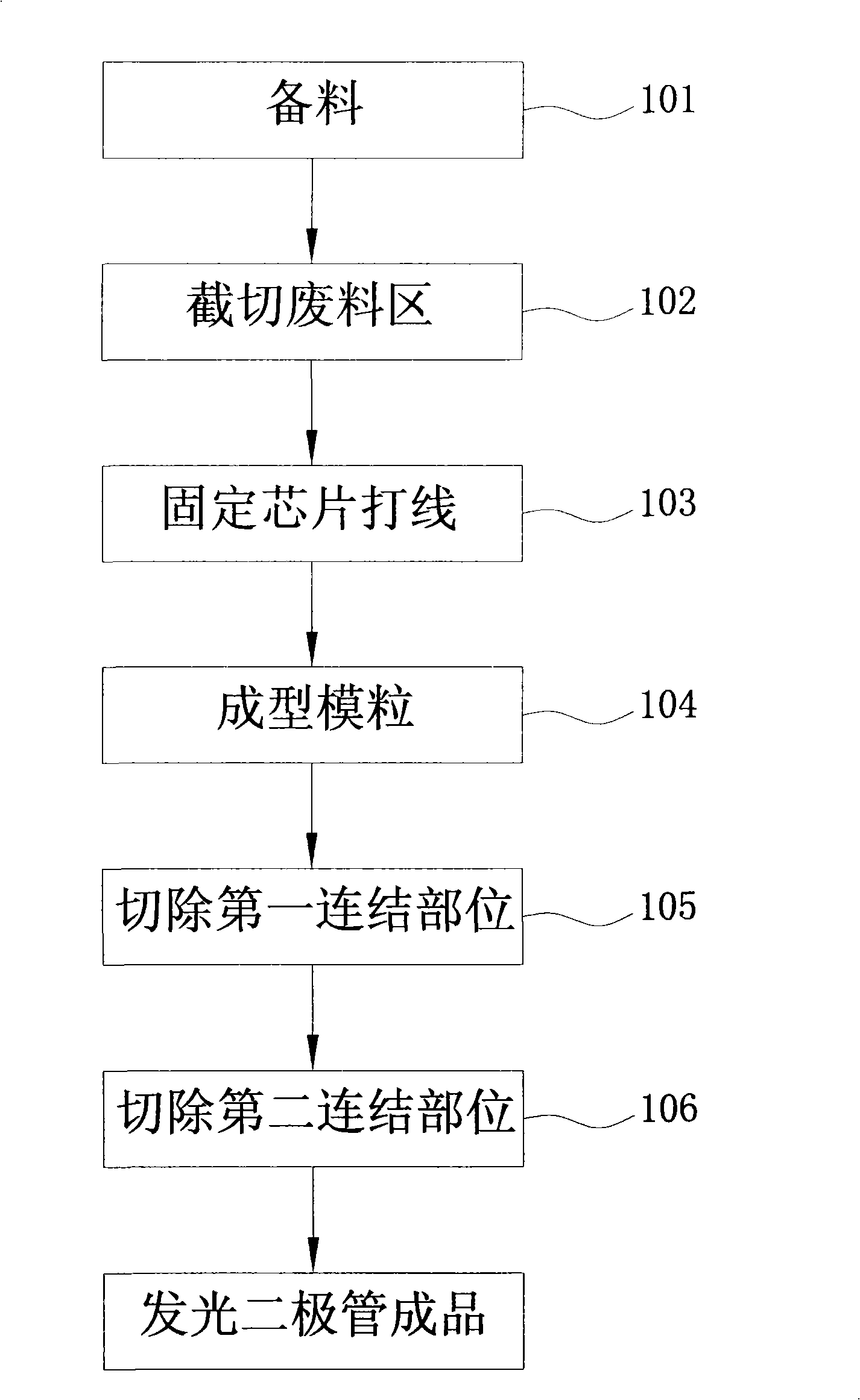

[0056] refer to Figure 8 , is a flowchart of the steps of an embodiment of the present invention.

[0057] The preparation method of the light-emitting diode of the present invention comprises the following manufacturing steps:

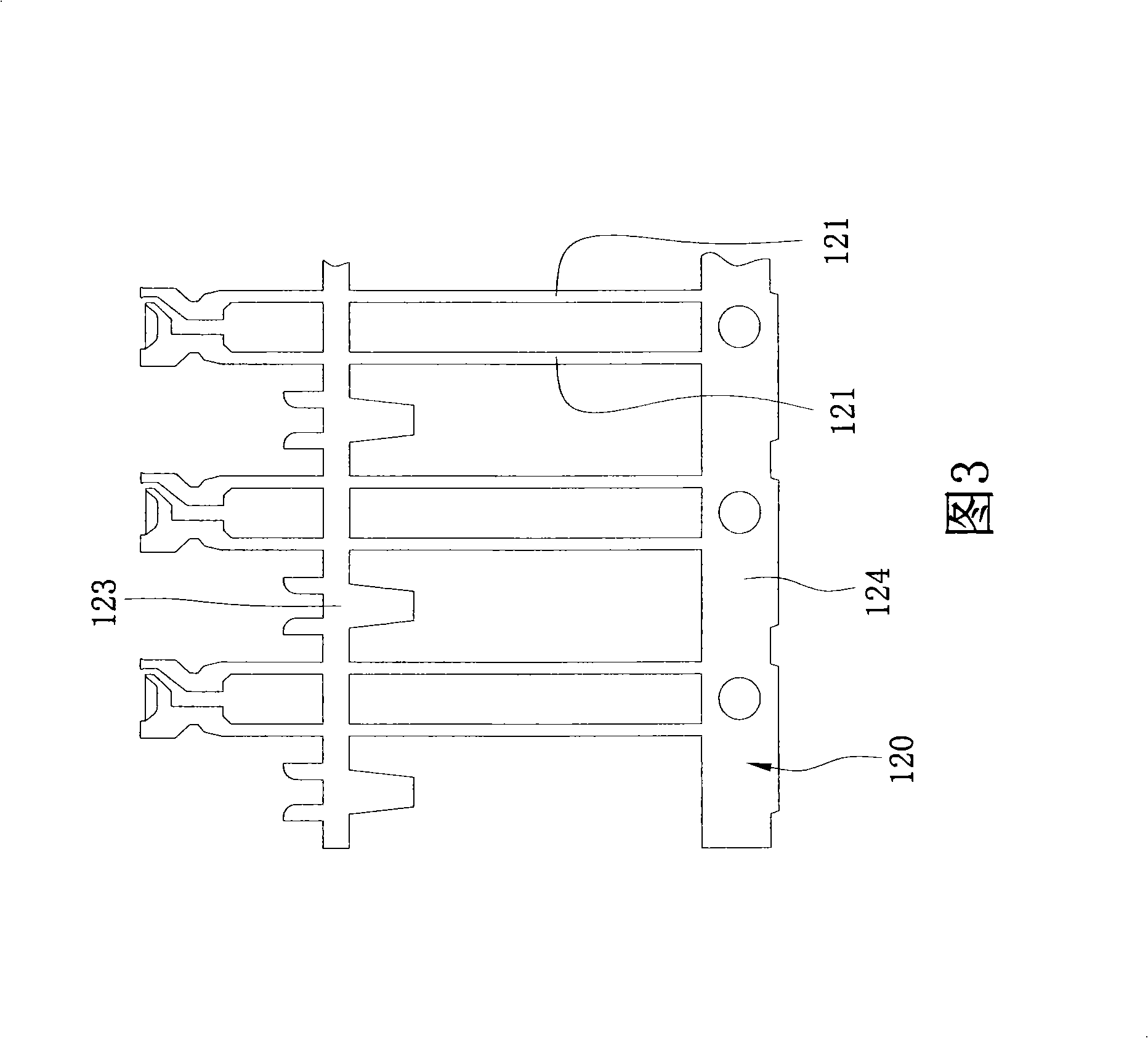

[0058] Step (1): Such as process 201 and reference Figure 9 and Figure 10 , forming a plurality of first brackets 210 and a plurality of second brackets 220 respectively.

[0059]Step (2): As shown in the process 202 and referring to FIG. 11 , the first brackets 210 and the second brackets 220 are fixed in pairs on the plurality of first mounting parts 310 and the plurality of On the loading portion 320 , a first bracket 210 and a second bracket 220 adjacent to each other form a bracket group 230 . And a clamp 400 is coupled to the jig body 300 to fix the first brackets 210 and the second brackets 220 .

[0060] Step (3): such as process 203 and reference Figure 12 , a chip 240 is fixed on a bowl groove 221 of the second bracket 220, and a w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com