Permanent-magnet brushless DC motor

A DC motor, permanent magnet brushless technology, applied in the field of motors, can solve problems such as insufficient performance, and achieve the effects of reducing the difficulty of assembly process, reducing costs, and improving magnetoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

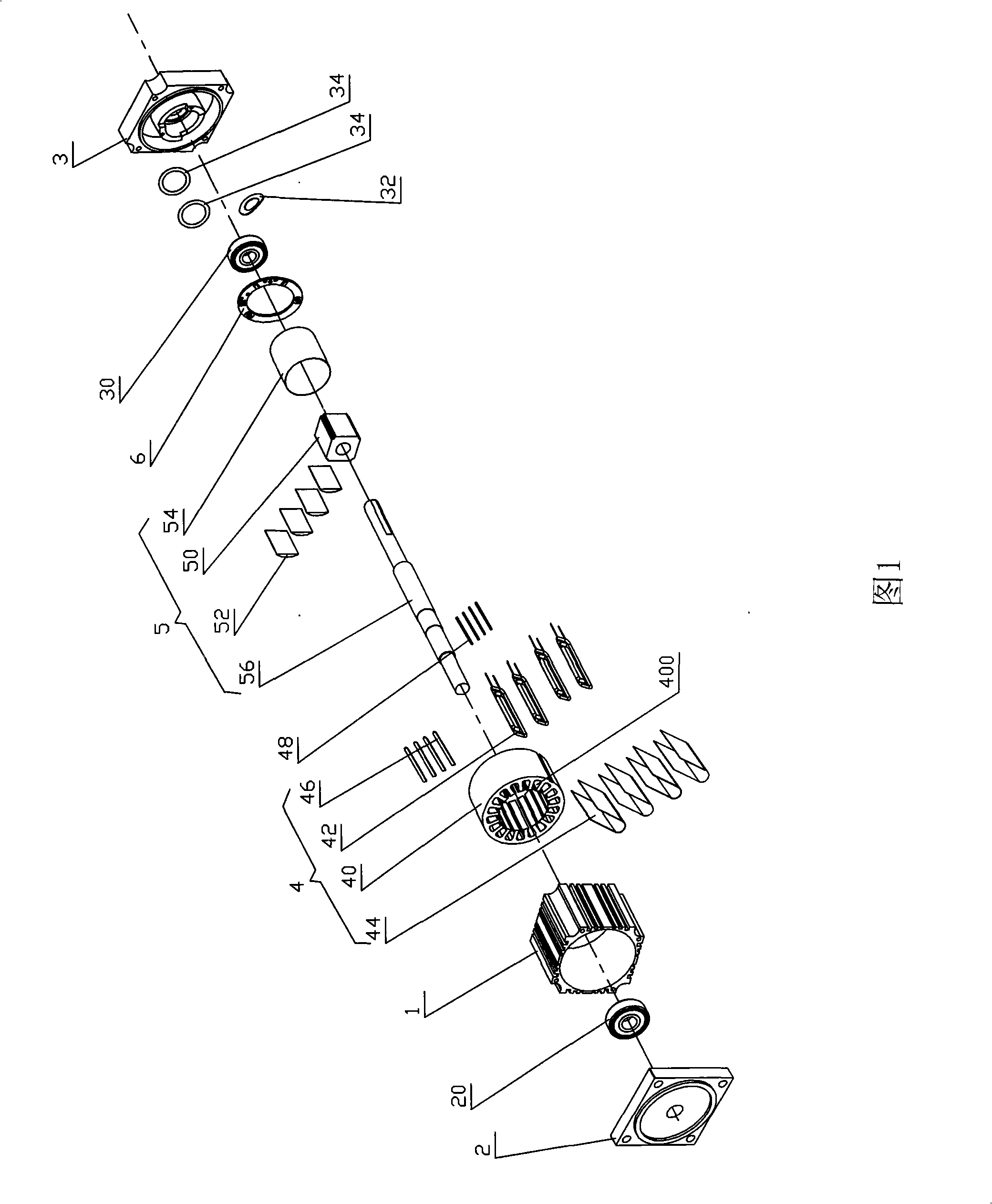

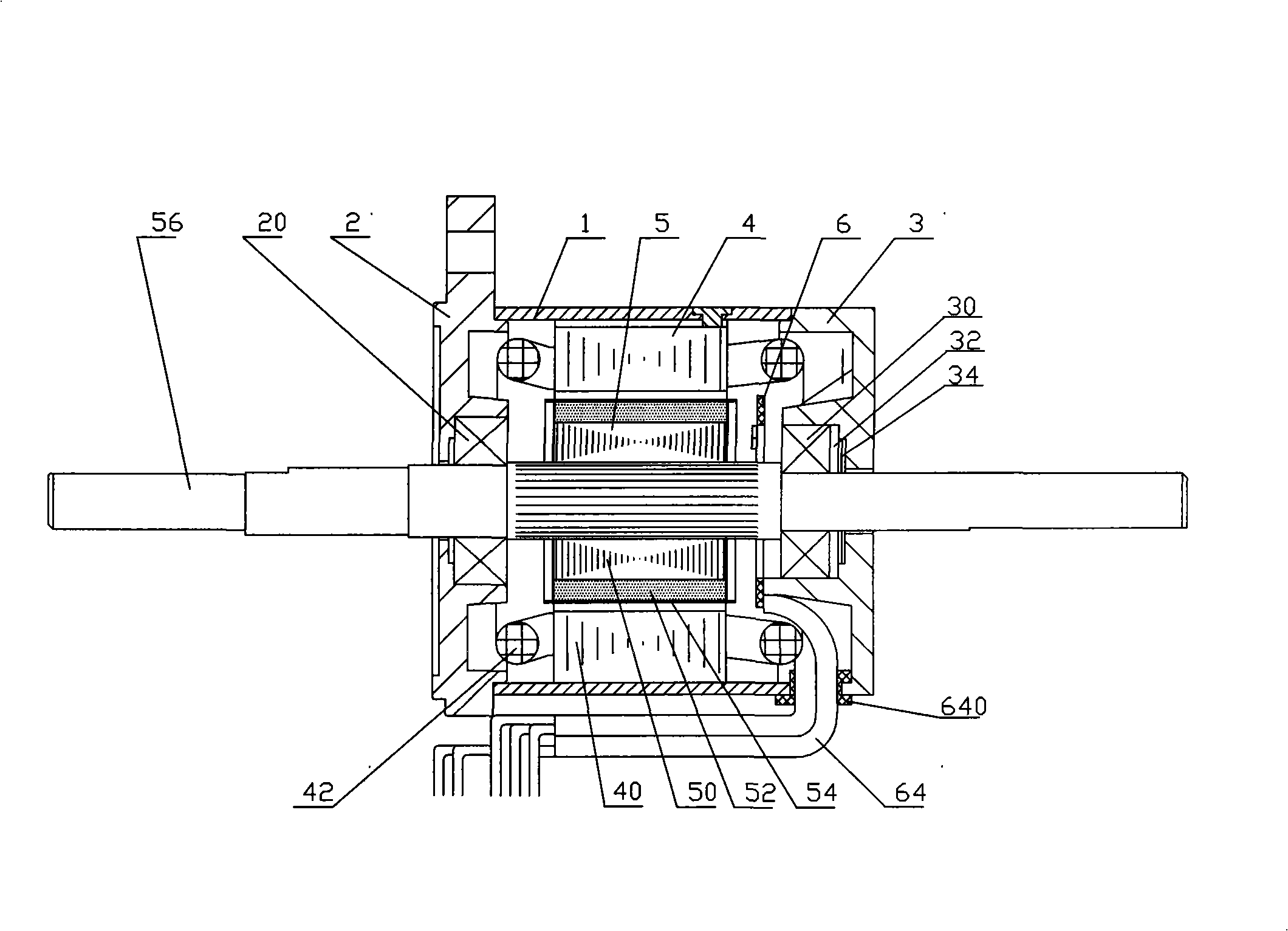

[0028] Please refer to Figure 1 together with figure 2 Shown is the permanent magnet brushless DC motor of the present invention, which includes a casing 1 , a front end cover 2 , a rear end cover 3 , a stator 4 , a rotor 5 and a position sensor 6 . The casing 1 is cylindrical. The stator 4 , the rotor 5 and the position sensor 6 are all disposed inside the casing 1 .

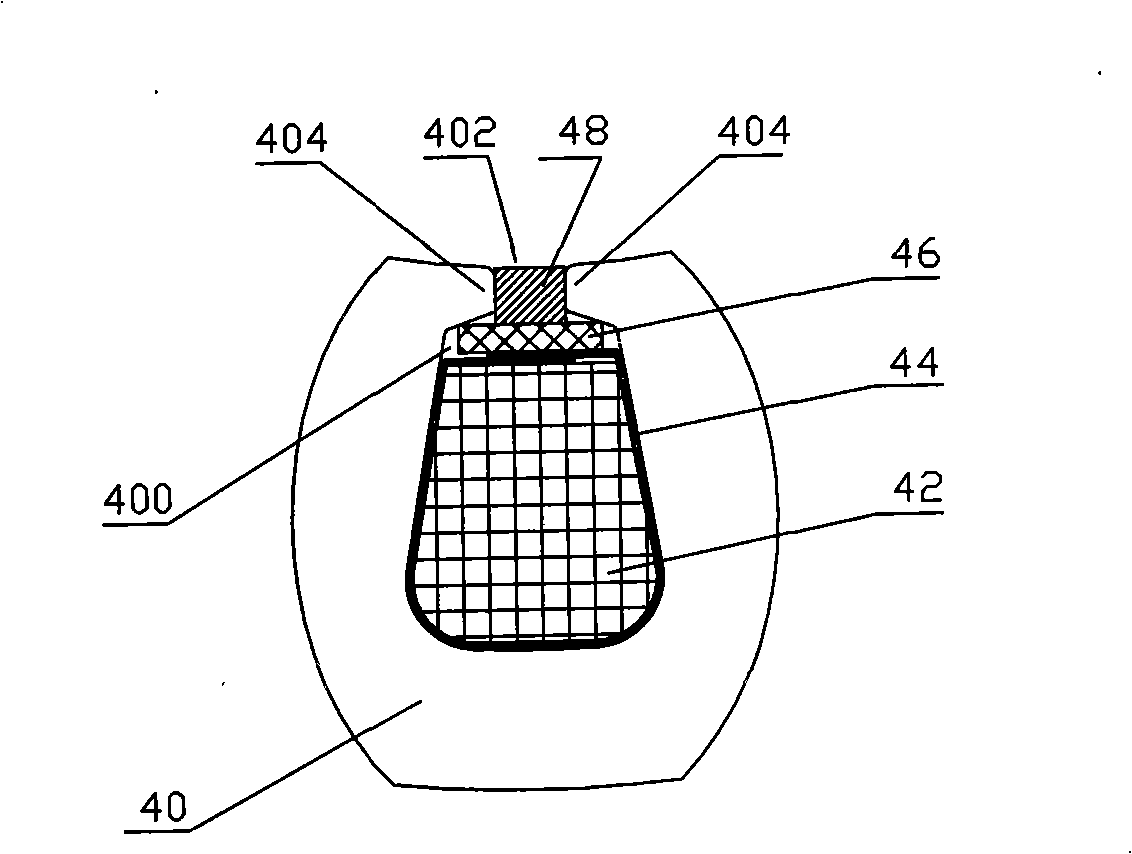

[0029] The stator 4 of the present invention includes a stator core 40 , a winding 42 , an insulating component 44 , a slot wedge 46 and a magnetically conductive insert 48 . The inner edge of the stator core 40 is provided with a plurality of tooth slots 400, and the winding 42 passes through the tooth slots 400 of the iron core 40, and the insulating member 44, the slot wedge 46 and the magnetically conductive insert 48 are all arranged on the stator core 40. 400 per cogging, see image 3 It is an enlarged view of a tooth slot 400 of the stator 4 .

[0030] The gullets 400 have a narrower notch 402 formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com