Flexible supporting mechanism for machining plate workpiece

A flexible support and support column technology, used in metal processing mechanical parts, workpiece clamping devices, metal processing equipment, etc., can solve problems such as workpiece support and positioning, and achieve stable and reliable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

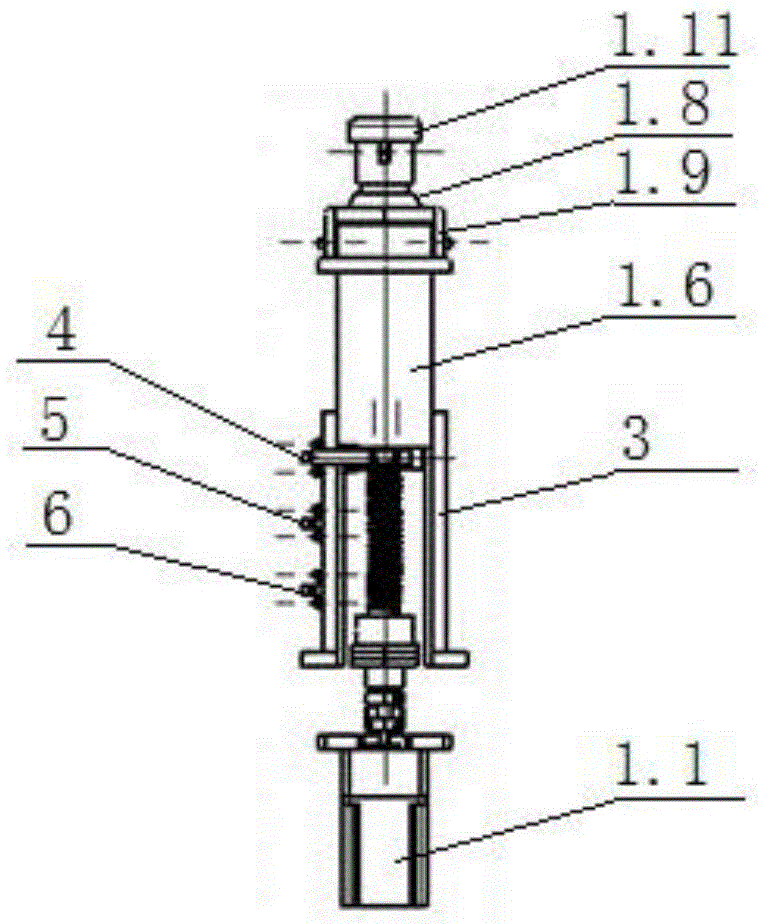

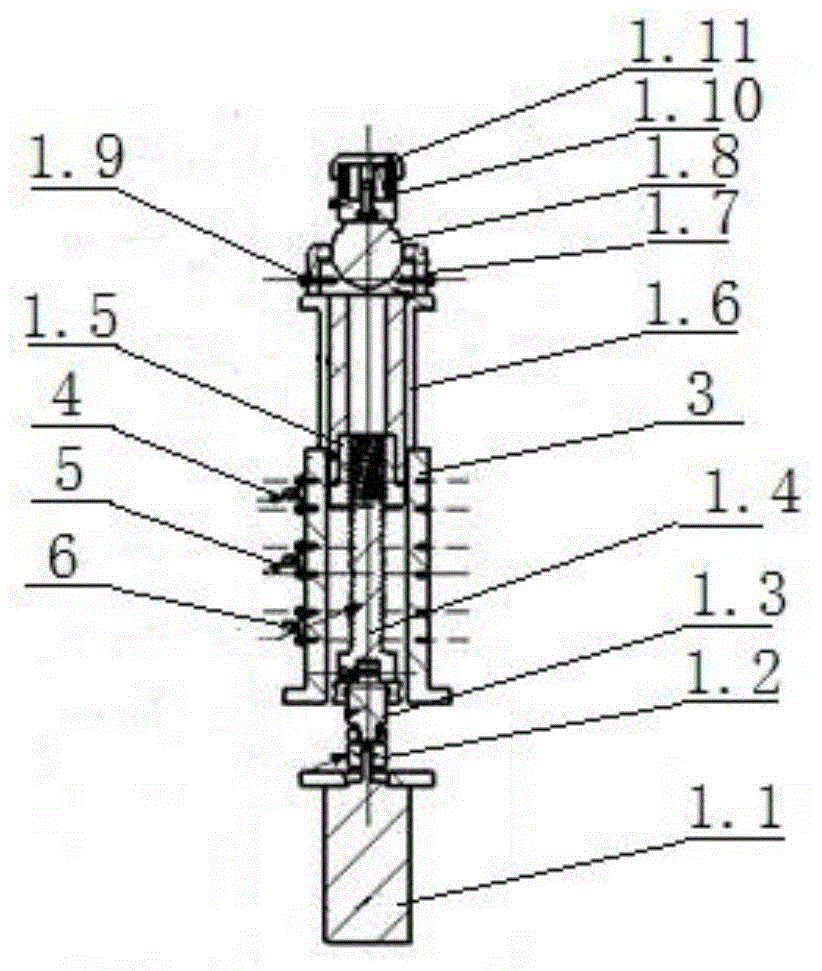

[0019] Embodiment 1: as image 3 As shown, a discrete support column is characterized in that: the shaft of the motor 1.1 is connected to one end of the connecting shaft 1.3 through a coupling 1.2, and the other end of the connecting shaft 1.3 is fixed on the lifting screw 1.4, and the outside of the lifting screw 1.4 has a trapezoidal thread. The nut 1.5 is set on the outside of the lifting screw 1.4, and the inner surface of the lifting nut 1.5 also has trapezoidal threads. The trapezoidal threads on the outside of the lifting screw 1.4 match the trapezoidal threads on the inside of the lifting nut 1.5. The lower end of the lifting sleeve 1.6 is fixed on the lifting nut 1.5. Universal ball joint seat 1.7 is fixed on the upper end of barrel 1.6, universal ball joint 1.8 is installed on universal ball joint seat 1.7, universal ball joint ferrule 1.9 is fixed on the outer side of universal ball joint 1.8, and the upper part of universal ball joint 1.8 is fixed with electromagnet...

Embodiment 2

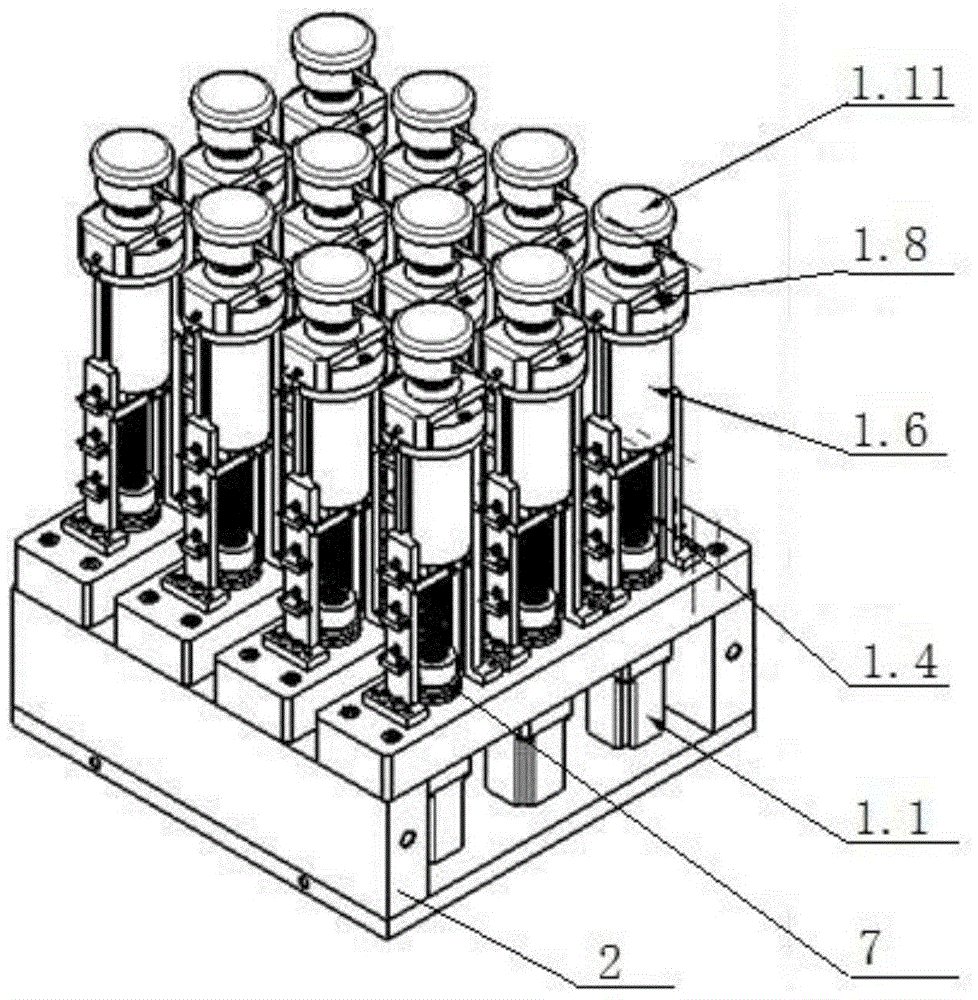

[0020] Embodiment 2: as figure 1 As shown, a flexible support mechanism for processing plate workpieces is characterized in that: the base 2 has two upper and lower layers, the discrete support column 1 passes through the upper layer of the base 2 and is fixed on the lower layer of the base 2, and the motor 1.1 of the discrete support column 1 is fixed On the lower layer of the base 2, the shaft of the motor 1.1 is connected to one end of the connecting shaft 1.3 through a coupling 1.2, the other end of the connecting shaft 1.3 is fixed on the lifting screw 1.4, the connecting shaft 1.3 is set in the thrust ball bearing 7, and the lower end of the thrust ball bearing 7 is placed On the upper layer of the base 2, the upper end of the thrust ball bearing 7 is in contact with the lifting screw 1.4. There is a trapezoidal thread on the outside of the lifting screw 1.4, and the lifting nut 1.5 is set on the outside of the lifting screw 1.4. The thread coincides with the trapezoidal...

Embodiment 3

[0021] Embodiment 3: A flexible support mechanism for processing plate workpieces, characterized in that: the base 2 has two layers, the discrete support column 1 passes through the upper layer of the base 2 and is fixed on the lower layer of the base 2, and the motor 1.1 of the discrete support column 1 Fixed on the lower layer of the base 2, the shaft of the motor 1.1 is connected to one end of the connecting shaft 1.3 through the coupling 1.2, the other end of the connecting shaft 1.3 is fixed on the lifting screw 1.4, the connecting shaft 1.3 is set in the thrust ball bearing 7, and one end of the thrust ball bearing 7 Placed on the upper layer of the base 2, the other end is in contact with the lifting screw 1.4. There is a trapezoidal thread on the outside of the lifting screw 1.4. The lifting nut 1.5 is set on the outside of the lifting screw 1.4. The inner surface of the lifting nut 1.5 also has a trapezoidal thread. The trapezoidal thread on the inner side of the lifti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com