A double-shield tbm spray-anchor support structure and its construction method

A technology of shotcrete anchor support and construction method, which is applied in the directions of bolt installation, earthwork drilling, vertical shaft equipment, etc., can solve the problems of delaying the progress of the project and increasing the investment of the project, and achieves the improvement of the project progress, high flexibility and timeliness. and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

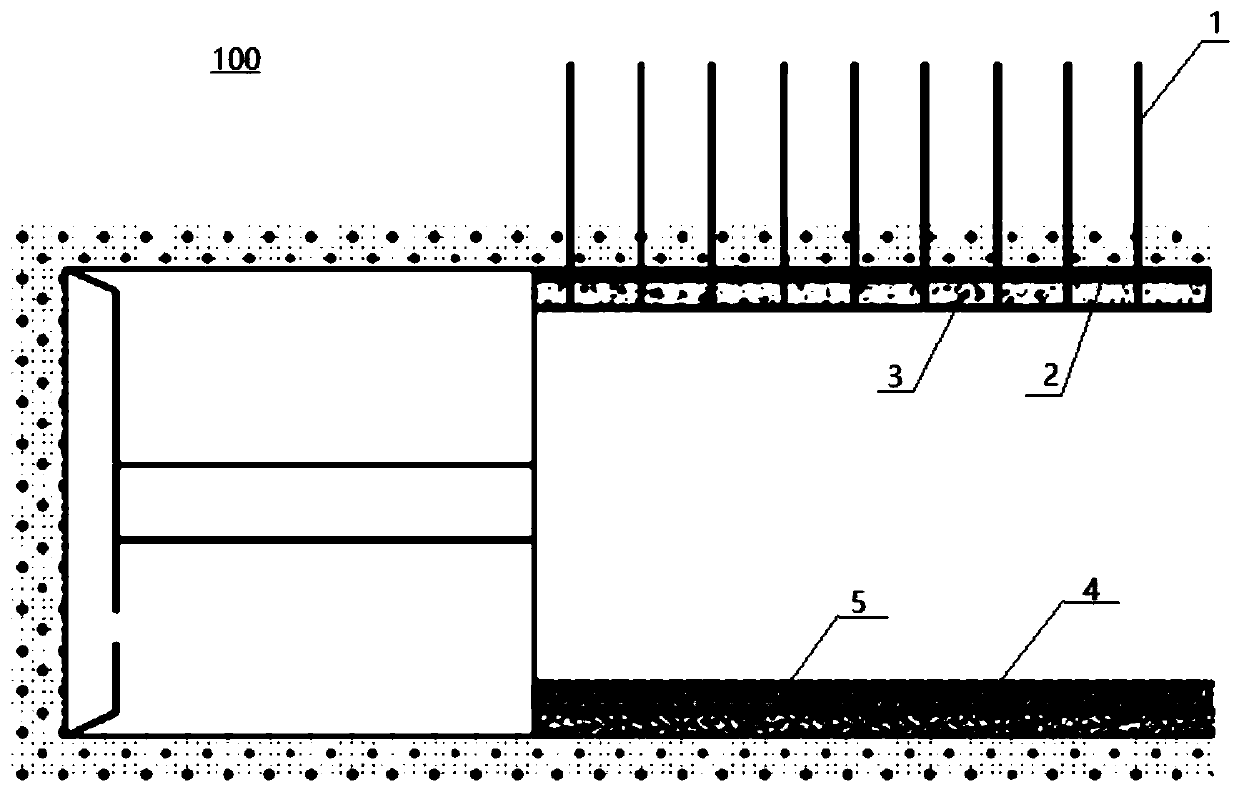

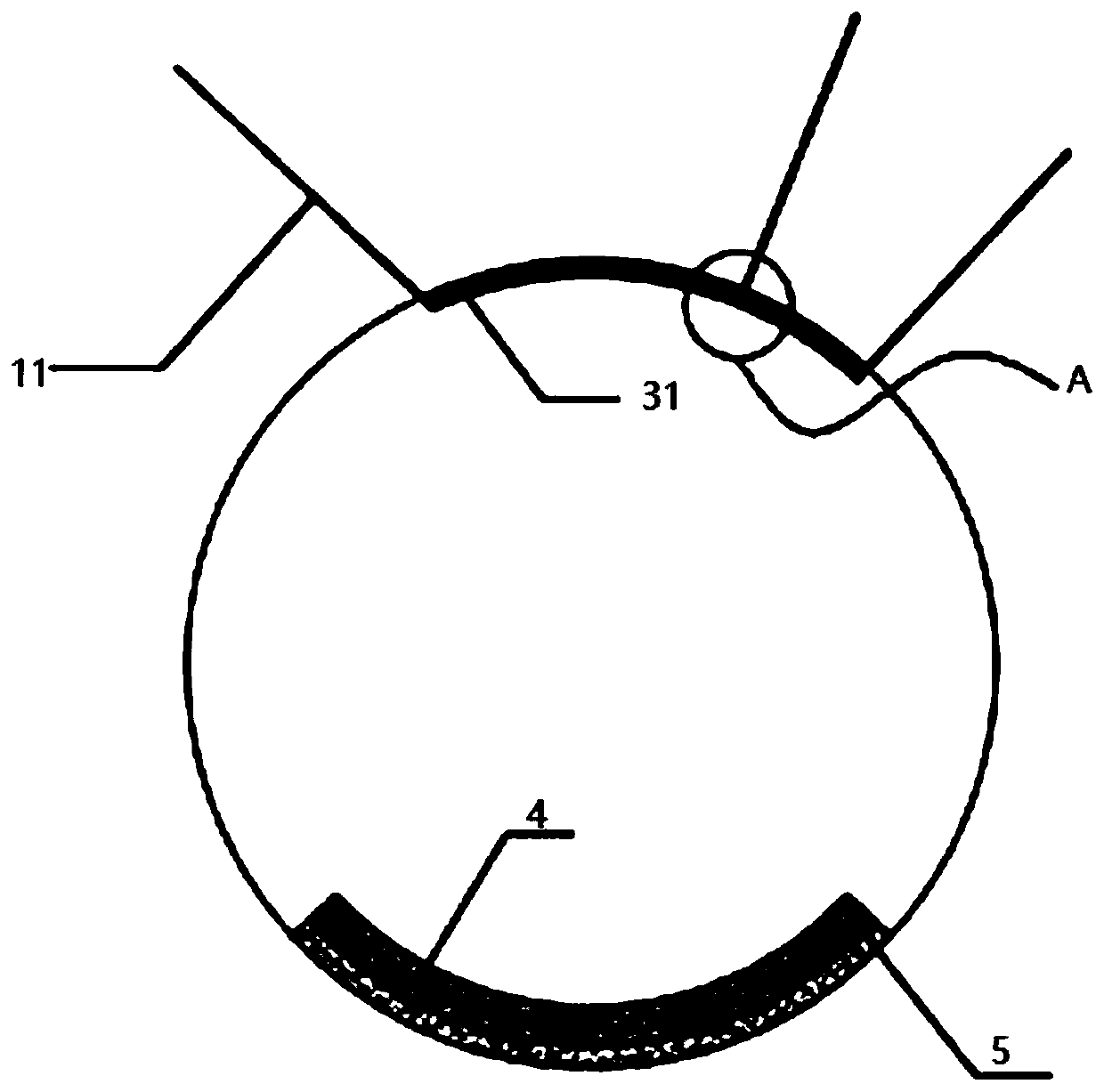

[0069] Figure 4 It is a double-shield TBM spray-bolt support structure 100: two pieces of C35 concrete segment 4 are used for surrounding rock lining at the bottom of the tunnel arch, and self-compacting concrete is filled into the cavity between the segment 4 and the surrounding rock at the bottom of the tunnel arch.

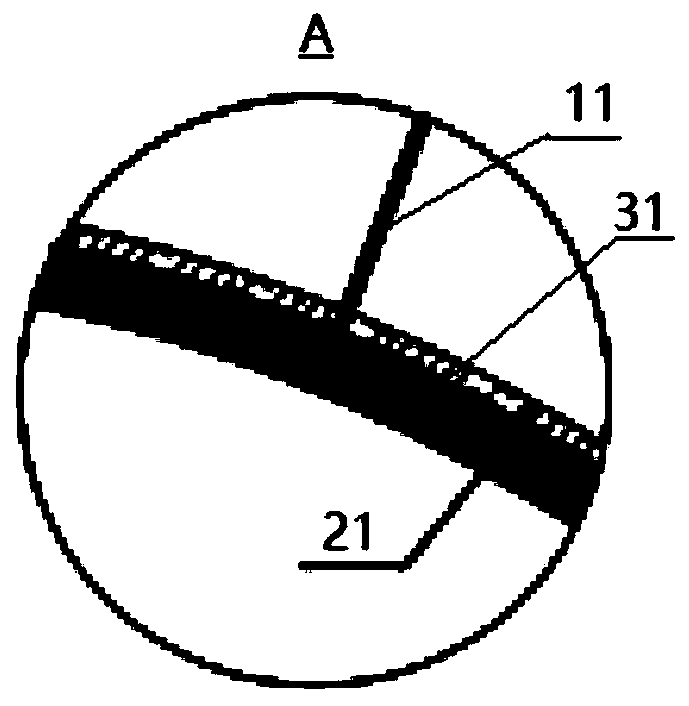

[0070] Both the first anchor rod 11 and the second anchor rod 12 are Φ22mm×L2000mm coiled anchor rods 1, and the initial spray anchor structure includes three first anchor rods 11, the first metal mesh 21 and the first concrete layer 31, and the three first anchor rods 11 Anchor rods 11 are randomly arranged within 30 degrees of the arch top of the tunnel. The first metal mesh 21 is braided by Φ8mm steel bars and hung on the end of the first anchor rod 11. The first concrete layer 31 is made of a C25 No. Formed by wet spraying of concrete, the thickness of the sprayed layer is 40mm.

[0071] The secondary shotcrete anchor structure includes the second anchor ...

Embodiment 2

[0073] Figure 5 It is another double-shield TBM spray-bolt support structure 100: two pieces of C35 concrete segment 4 are used for surrounding rock lining at the bottom of the tunnel arch, and self-compacting concrete is filled into the cavity between the segment 4 and the surrounding rock at the bottom of the tunnel arch . Both the first anchor 11 and the second anchor 12 use Φ22mm×L2500mm coiled anchor 1. The initial spray anchor structure includes five first anchors 11, the first metal mesh 21 and the first concrete layer 31, five The first anchor rods 11 are randomly arranged within 40 degrees of the vault, the first metal mesh 21 is laid on the top surrounding rock fracture zone and fixed at the end of the first anchor rods 11, and the first concrete layer 31 is made of C25 concrete 2 Formed by wet spraying, the thickness of the sprayed wet layer is 50mm.

[0074]The secondary shotcrete anchor structure includes the second anchor rods 12, the second metal mesh, the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com